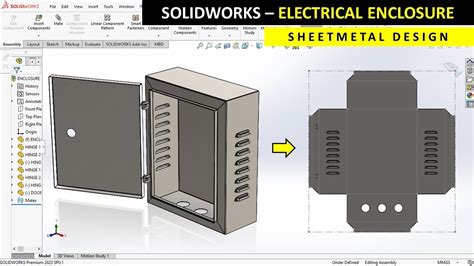

designing sheet metal enclosure fabrication cleco How do you design a sheet metal enclosure? The first step is to get familiar with product requirements, both functional and aesthetical. Then, you can go ahead with choosing the material that best fits your manufacturing needs.

And as long as Romex is permitted in your location, your use of the box clamps is fine too.

0 · welding sheet metal enclosure

1 · sheet metal enclosure design guide

2 · sheet metal enclosure bending

3 · metal enclosure design and fabrication

4 · manufactured metal enclosure design

5 · how to fabricate metal enclosure

6 · how to design a metal enclosure

7 · carbon steel enclosure design

$12.88

welding sheet metal enclosure

The fabrication process of these enclosures requires precision and efficiency to ensure a perfect fit and optimal performance. One essential tool that can make a significant difference in the . Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It . Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.

Explore essential principles of sheet metal enclosure design, from materials to testing standards, ensuring durability and functionality for various applications.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

How do you design a sheet metal enclosure? The first step is to get familiar with product requirements, both functional and aesthetical. Then, you can go ahead with choosing the material that best fits your manufacturing needs. Designing a sheet metal enclosure requires careful consideration of material selection, design considerations, manufacturability, and finishing options. By following these . The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished .

Sheet metal enclosures are protective casings made from thin metal sheets that house electronic components or machinery. They provide shielding, durability, and aesthetic appeal to the .

The fabrication process of these enclosures requires precision and efficiency to ensure a perfect fit and optimal performance. One essential tool that can make a significant difference in the quality of sheet metal enclosure fabrication is the Cleco fastener. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t)

Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.Explore essential principles of sheet metal enclosure design, from materials to testing standards, ensuring durability and functionality for various applications. Sheet metal enclosures offer numerous manufacturing advantages, including faster turnaround times and reduced manufacturing costs. Explore tips and best practices for designing sheet metal enclosures.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

How do you design a sheet metal enclosure? The first step is to get familiar with product requirements, both functional and aesthetical. Then, you can go ahead with choosing the material that best fits your manufacturing needs. Designing a sheet metal enclosure requires careful consideration of material selection, design considerations, manufacturability, and finishing options. By following these guidelines, engineers can create functional, durable, and aesthetically pleasing enclosures for a wide range of applications.

sheet metal enclosure design guide

The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished enclosure meets all technical specifications and quality standards.Sheet metal enclosures are protective casings made from thin metal sheets that house electronic components or machinery. They provide shielding, durability, and aesthetic appeal to the enclosed equipment.The fabrication process of these enclosures requires precision and efficiency to ensure a perfect fit and optimal performance. One essential tool that can make a significant difference in the quality of sheet metal enclosure fabrication is the Cleco fastener. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t)

Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.

Explore essential principles of sheet metal enclosure design, from materials to testing standards, ensuring durability and functionality for various applications. Sheet metal enclosures offer numerous manufacturing advantages, including faster turnaround times and reduced manufacturing costs. Explore tips and best practices for designing sheet metal enclosures.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. How do you design a sheet metal enclosure? The first step is to get familiar with product requirements, both functional and aesthetical. Then, you can go ahead with choosing the material that best fits your manufacturing needs.

Designing a sheet metal enclosure requires careful consideration of material selection, design considerations, manufacturability, and finishing options. By following these guidelines, engineers can create functional, durable, and aesthetically pleasing enclosures for a wide range of applications. The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished enclosure meets all technical specifications and quality standards.

Update: for all the good answers I received, I cannot find a device for making a waterproof 4-way underground splice. If you can't do 4 cables all .

designing sheet metal enclosure fabrication cleco|carbon steel enclosure design