cnc machine shop rate The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime . When you peer out into your front yard, you may have noticed those inconspicuous metal boxes that likely blend into the surroundings. These unassuming structures are known as padmounted transformers, and they play a crucial role in powering your home.

0 · machine shop hourly rate calculator

1 · machine shop hourly rate

2 · how expensive is cnc machining

3 · cnc machining hourly rate

4 · cnc machining cost

5 · cnc machine hourly rate calculator

6 · cnc cutting cost

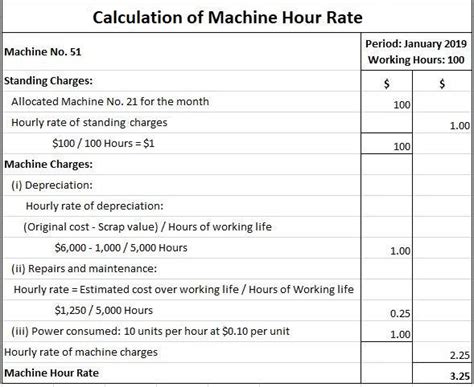

7 · calculating machine cost per hour

We've rounded up 34 specific colors that look beautiful with black fridges, ovens, .

I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the . The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime .In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I . CNC Machine Hourly Rate Calculator. The basic strategy is to determine the machine’s Total Cost of Ownership (TCO) over its useful life .

Here's the formula I use: Gross Sales – Materials/number of work days per month/number of production employees/direct man hours per day per employee = shop rate. This gives you .

Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that . Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.

In time of low work, its amazing how quickly shop rates drop to break-even or even in the red just to keep the cash flow going. The best way to keep and secure a profitable rate .According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors .

machine shop hourly rate calculator

I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the 0 - 0 range depending on how much the job should cost to run. The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate. 60 to 80 dollars per hour is the average machine shop rate in most parts of the U.S.. Electricity is and overhead costs play an important role in what a shop is charging. However, the most important factor would be quality and type of shop.

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I could. Some values could be argued as too low or too high, but the idea is the same. The plan is as follows:

CNC Machine Hourly Rate Calculator. The basic strategy is to determine the machine’s Total Cost of Ownership (TCO) over its useful life and then divide that by how many hours it will be used. Here’s a quick video demo of the hourly rate calculator:

Here's the formula I use: Gross Sales – Materials/number of work days per month/number of production employees/direct man hours per day per employee = shop rate. This gives you your loaded shop rate, meaning overhead and profit are already included. If you want to calculate an unloaded rate, you would delete those 2 numbers from the equation. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes. In time of low work, its amazing how quickly shop rates drop to break-even or even in the red just to keep the cash flow going. The best way to keep and secure a profitable rate is to offer services that are specialized, in demand, and with very few local competitors. Of .

According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors above.I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the 0 - 0 range depending on how much the job should cost to run. The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate. 60 to 80 dollars per hour is the average machine shop rate in most parts of the U.S.. Electricity is and overhead costs play an important role in what a shop is charging. However, the most important factor would be quality and type of shop.

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I could. Some values could be argued as too low or too high, but the idea is the same. The plan is as follows: CNC Machine Hourly Rate Calculator. The basic strategy is to determine the machine’s Total Cost of Ownership (TCO) over its useful life and then divide that by how many hours it will be used. Here’s a quick video demo of the hourly rate calculator:Here's the formula I use: Gross Sales – Materials/number of work days per month/number of production employees/direct man hours per day per employee = shop rate. This gives you your loaded shop rate, meaning overhead and profit are already included. If you want to calculate an unloaded rate, you would delete those 2 numbers from the equation. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense.

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.

In time of low work, its amazing how quickly shop rates drop to break-even or even in the red just to keep the cash flow going. The best way to keep and secure a profitable rate is to offer services that are specialized, in demand, and with very few local competitors. Of .

moody's sheet metal works

most advanced cnc machine

What do metal stars on houses actually mean? These metal stars allegedly originate from German settlers who came to Pennsylvania between 1727 and 1775, all of whom emigrated from the Rhine region of Germany.

cnc machine shop rate|cnc cutting cost