sheet metal bend chart Bend forming 0°L=A+B-0.43T, T=Thickness, Deduction=0.43T Formula: L(unfold length)=A(Outside size)+B(Outside size)-K(K-factor) None-90° bend unfold according to the neutral layer, the distance from neutral to sheet inner side is T/3, . See more Our No Assembly Box Spring is not your average foundation. Its folding design not only makes set-up insanely easy, but it also comes in handy on moving day, maneuvering easily in and around tight hallways and corners.Storage Star Twin Falls has the space you need to organize your home or business right here in Twin Falls. Our clean, fully fenced storage facility is loaded with convenient features and security measures, like drive-up access,. read .

0 · sheet metal minimum bend length

1 · sheet metal bending radius chart

2 · sheet metal bending angle chart

3 · sheet metal bending allowance charts

4 · sheet metal bend tolerance chart

5 · sheet metal bend table

6 · sheet metal bend allowance table

7 · fractory sheet metal folding chart

In this blog, we will explore the process of how to tune a sealed subwoofer enclosure for maximum performance. We'll dive into the basics of sealed subwoofer enclosures, the role of Thiele/Small parameters, the advantages of sealed subwoofer enclosures, and the steps involved in tuning your subwoofer box.

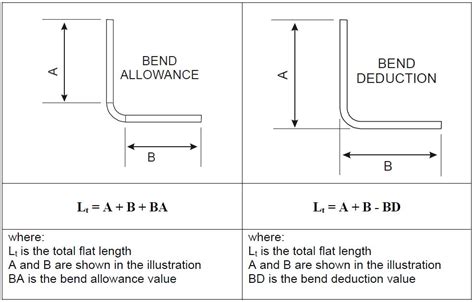

Bend allowance is a critical concept in sheet metal fabrication, particularly in the design and manufacturing of press-bent parts. It refers to the additional length of material required to accommodate a bend in the sheet metal. This allowance ensures that the final dimensions of the bent part match the design . See moreAfter learning about bend allowance, the next step is to calculate it. Bend allowance is a critical factor in sheet metal fabrication, as it determines the amount of material needed to accommodate a bend. This ensures that the final dimensions of the part are accurate . See moreOne of the easiest ways to calculate bend allowance is by using a bend allowance calculator. These calculators are designed to quickly and . See moreBend forming 0°L=A+B-0.43T, T=Thickness, Deduction=0.43T Formula: L(unfold length)=A(Outside size)+B(Outside size)-K(K-factor) None-90° bend unfold according to the neutral layer, the distance from neutral to sheet inner side is T/3, . See more

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend .The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

sheet metal minimum bend length

Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our .Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors .

Introduction. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being .

With this chart, you can save time and increase efficiency in your bending process.. Additionally, our press brake tonnage calculator can assist you in calculating the required bending force for your specific sheet metal product.. .

In sheet metal fabrication, curving sheets according to a specific bend radius is one of the most common operations used to create flanges, curls, seams etc.Moreover, bending imparts much strength to the sheet metal . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .Sheet Metal Bend Gains Chart Attention Sheet Metal CAD Experts Don’t settle for K factor .5, use these specific bend gains so your manufacturer can use your native CAD model without them wasting time by having to recreate a flat pattern of your sheet metal fabricated parts. The below Microsoft Excel chart is for even numbered gauges 8 through 24 and has a default K-Factor of .33 for each. Calculation Example. Bend allowance is important because it gives us the information to cut sheet metal to produce a bent metal piece accurately.

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.Bend Allowance Chart K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33Bending diagram Image credit: https://www.custompartnet.com Bending Direction. Sheet metal displays anisotropic behavior when being bent, and direction matters to prevent general manufacturing defects like cracks and tears during the bending process. If sheet metal is bent in line with the direction of the metal fibers, the likelihood of experiencing a crack or tear at the . Thus, understanding the bend allowance or bend deduction is a crucial first step to understanding how sheet metal parts are fabricated for the metal forming and fabricating industry. 1. Bend allowance calculation formula:

Bend Deduction Chart K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33 K factor 0.33An Air Bend Force Chart, or Force Chart breaks down a number of key components of sheet metal bending in an easy to reference format. Being able to read a bend force chart is crucial for any Brake Press operator and sheet metal engineer. The gauge, inside radius, die opening, and minimum flange length are all interconnected through different equations and relationships, the . For instance, if the sheet metal to be bent is mild steel, with a thickness of 4mm and a bending length of 3.2m, the theoretical width of the bottom die opening should be 8 times the thickness, which is 32mm. Input these figures into the calculator above (remember the units are in mm), and we get a value of 106.12 Ton. This means you’ll need a minimum bending . Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. Our Sites . FMA; The Fabricator; FABTECH; . This chart shows a minimum bend radius of 0 to 1 times the material thickness for 0.125-in.-thick 5052-H32. This is slightly different .

Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into:

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii. The minimum permissible radii will also vary with the design and condition of the tooling. How to design bend reliefs for sheet metal with CAD software. There are two common ways to add bend relief to your design. One way is to do it manually. This is an option in any tool you use to create your design. The .Use this Air Bending Force Chart to help you select the correct V opening in your die to get the bend that you want and ensure your tool selection is safe.

EXEMPLE 2 for metal sheet bending tables. We have a metal sheet of 5 m/m thickness in INOX (with a hardness of 70Kg/mm2), in this case we must look at the small square inserted in the table. We observe in the lower part the value T (N/mm2), the hardness of this material is 700 N/mm2, that is to say 70Kg/mm2, if we go to the C value it gives us . Sheet metal bending is a versatile field that allows for designs ranging from complex to simple to be created in a cost effective and efficient manner.As with all manufacturing processes and design applications, specific rules of thumb should be used to ensure that appropriate features are created that allow for ease of manufacture.

A sheet metal bend radius chart is a valuable tool that provides engineers and fabricators with essential information. It typically lists various materials and their corresponding recommended bend radii. Think of it as a cheat sheet for ensuring your metal sheets stay intact during the bending process. 3. The Rule of Thumb for Sheet Metal Bend . We use the Bend Deduction formula every day at Approved Sheet Metal to compute our standard sheet metal bend gains chart. This chart serves as a handy reference for bend deductions with a variety of materials and thicknesses, and is a valuable resource for understanding how sheet metal stretches when bent. However, this design also has some drawbacks, such as low bending strength and a tendency for the sheet metal to fracture easily. The pressing process is a type of stamping process where a partially extruded material is used to force a groove onto the sheet metal, making it easier to bend and improving bending accuracy. This example demonstrates how to apply the K-factor calculation formula to determine the K-factor for a specific sheet metal bending scenario. K Factor Chart. The following are K-factors for common metal materials. Soft copper or soft brass: K=0.35; Semi-hard copper or brass, mild steel, aluminium etc.: K=0.41 .

Understanding the Bend Deduction and consequently the Bend Allowance of a part is a crucial first step to understanding how sheet metal parts are fabricated. When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched. As this happens you gain a small amount of total length in your part. If a bending radius different from the plate thickness is required, a special die must be used for processing. When the sheet metal drawing calls for a 90-degree bend with a particularly small bending radius, the sheet metal should first be grooved and then bent.. Special press brake tooling, such as punches and dies, can also be used.

distribution box bunnings

distribution box l6-30r

American Turned Products specializes in the machining of high volume, highly complex components for the Automotive, Fluid Power, Oil & Gas, and other markets both domestically and worldwide.

sheet metal bend chart|sheet metal minimum bend length