cnc machine tool offset CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting

0 · what is tool offset

1 · what is tool length offset

2 · tool offset meaning

3 · tool offset definition

4 · offset turning on cnc lathe

5 · offset meaning in cnc programming

6 · fixture offset cnc

7 · cnc tool offsets explained

John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s.

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

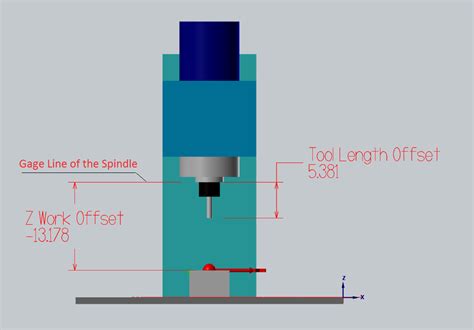

By letting the machinist set a z-axis datum for each part, the tool length offset enables the CNC machine to compensate for many tools of different lengths. This ultimately enables machinists to use multiple tools without .

what is tool offset

what is tool length offset

CNC Tool Length Offsets Explained. This video is talking about the 3 most common Tool Length Offsetting methods used on CNC milling machines, and the pros and cons of each.CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best .Tool Length Offset remains the same between many machines. You can just pull the tool out of one machine, Put it into the other one, Type in its Tool Offset and off you go. There is no need to touch off the tool again. Positive offsets are the . How to Identify Tool Length Offset? 1. Check the simulation results and actual workpiece to ensure they match. If the edges are not properly processed, or the thickness is .

The CNC machine needs some way of knowing how far each tool extends from the spindle to the tip. This is accomplished using a Tool Length Offset (TLO). G43 is the code which directs the .Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By .This video is talking about the 3 most common Tool Length Offsetting methods used on CNC milling machines, and the pros and cons of each method. Method 1 - For this first method, you will assemble the tool and load it into the spindle of . The machine should know the offset between the reference point of first tool and that of the next tool, when the tools are brought into the cutting positions. This is called tool offset. If the WCS is set up using a particular tool, it may be called the master tool, for which tool offset would be zero (in ideal case).

What are cnc machine offsets? Cnc machine offsets or work coordinate system (WCS) are positions you set that are referenced from your machines home position. You can set multiple offsets in a program.This is usually done when .Make sure that the tool offsets you’re setting for your work offset, match the work offset that your machine is actually running. If you’re trying to set tool offsets for a g54 work offset but your machine is still running, say g57 , from a previous program, .Tool Offsets Explained. Have you ever looked at the tool offset screen on your Haas mill and wondered what all those columns are for? In this Tip of the Day, Mark covers the topic in detail, giving you all the answers. Whether you set your tool offsets manually or with a probe, anyone who programs or operates a machine needs to watch this video.

Hi thanks for adding me. This is a new problem and we are stumped. Mazak Quickturn Nexus350myII Using G-code Mastercam 2017. (Same issue with Mastercam X5) Something changed we believe in a parameter or setting.In lathe mode used to be able to use 2 offsets for 1 tool. Eg. tool 1 offset 21 or. 2 Global Offset System 2.1 Why Global Offset A CNC machine tool is designed with a table to mount a fixture and locate a part on the fixture for machining. The fixture is aligned to the table and the table is installed on the CNC machine. Due to imperfections in the machine and fixture manufacturing, the actual table center and fixture center . Tool offset is the relative displacement applied to the coordinate axes of a machine tool during all or a specified part of a machining program. . In the CNC machine tool-turning process, using the tool compensation function can be programmed according to the size of the workpiece profile.

2 Global Offset System 2.1 Why Global Offset A CNC machine tool is designed with a table to mount a fixture and locate a part on the fixture for machining. The fixture is aligned to the table and the table is installed on the CNC machine. Due to imperfections in the machine and fixture manufacturing, the actual table center and fixture center . When the conditions and therefore the targets change, we’ve to vary the work offset. On the opposite hand, the tool offset remains equivalent. Tool offsets -Depend on the change in geometrical shapes and sizes. Work offsets- depend upon the workload and therefore the required output. Tool offset has three main components. CNC programming is essential for accuracy and efficiency in machining operations within the manufacturing industry. This article explains what G10 CNC code does, a command to set tool offsets and manage coordinate systems on CNC machines. We have tried to give an all-around comprehension of the working of G10 commands backed up by theoretical concepts . Tool radius compensation allows the CNC machine to adjust the toolpath based on the actual size of the cutting tool used. With G41 (left-hand side) or G42 (right-hand side) active, the machine offsets the programmed path inward or outward by half of the tool’s diameter, resulting in accurate cuts.

tool offset meaning

The global offset for a machine tool is estimated through a model while utilizing the computed deviation between the measured and nominal dimensions of the part. Furthermore, the paper presents several other compensation concepts supporting the global offset method. . CNC machine tool is universal machinery in industry, and each product has . You also learn that a tool table is done by programming offsets. Crawfordsn: . Begin by referencing your CNC machine’s manual or seeking online tutorials for guidance tailored to your specific machine model. Typically, the process involves homing the machine, setting the workpiece in place, and then defining the work offset coordinates. .Use Macros to Speed Up Setting Tool Offsets - Haas Automation Tip of the Day. We've made lots of videos where Mark looks at setting the tool and work offsets on your mill. Now he's adding another one and showing us a quick way to set one tool offset or many tool offsets using some simple to understand macro statements. Learn the process of finding and storing a Work Offset on a 3-Axis CNC Mill.

The machine adds the two values together to determine the total tool length offset. This point will be explained later in your CNC training. Fig. 2.3 Ways to Set Tool Length Offset (TLO) (Image: “Vertical Milling Center Machine Motion” by LamNgeun Virasak, Manufacturing Processes 4-5 is licensed under CC BY-SA 4.0) and it works the way I want, it goes to the Z reference position and the tool length offset is gone. If I use "G91 G49 Z5.0" or "G91 H0 Z5.0" the machine will first make a Z movement in rapid that is equal to the inverse of the tool offset, meaning that if my tool is 1" long, the machine will first rapid Z-1" and then move up 5" incrementally.

With the development of the high-speed machine tools, linear guide has been an important element in machine tools. It is important to analyze the kinematic errors to improve the positioning precision.

.001 to.002 is not a sufficient move to make a cut. You are rubbing the tool with a cut adjustment of that depth. You need to adjust by more than the width of the radius/edge of your tool to produce a proper chip and not rub/burn your tool. You run your tool depth for your chamfer, measure it, adjust to depth, then cut a new chamfer. In this video, I talk about coordinate systems, types of CNC machines, tool offsets, and how to understand the axes on a CNC machine. For further informatio.On almost all cnc machine controls the tool offset setting and cnc machine zero offset setting ( workshift value, shift value, machine zero offset value) are given on separate pages. But these cnc controls also allow the cnc programmer to add offset values through cnc program. On Fanuc cnc controls we can use G10 (Programmable Offset Setting .I currently set all my tool offsets using a Renishaw tool setting arm on a fanuc lathe. I select T1(with no offset called) and touch off the probe in Z and X. This automatically alters offset 01. . A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc Members Online.

The Global Offset for a machine tool is estimated through a model while utilizing the computed deviation between the measured and nominal dimensions of the part. Examples are provided to . The general format for tool length compensation commands is G43 or G44, followed by the Z-axis end value and the tool length offset storage address (H). For example: G43 Z H or G44 Z H. The H represents the tool length compensation offset number, ranging from H00 to H99. Example of tool length compensation with G43 code (3-aix milling machine . The formulas are as if the machine X0Z0 is the C/L of the B-axis rotation and the probed bore is programmed X0Y0 with the probed face as Z0. If you have a machine where machine X0Z0 are in another location (usually all the way plus) you would need to .

G49 is a G-code command that cancels the tool length offset (TLO) applied by G43 or G44. TLO is a method of compensating for the difference in length between different tools used in CNC machining. TLO allows the CNC machine to adjust the Z-axis position according to the length of the current tool, so that the programmed coordinates are always .

tool offset definition

This video is talking about the 3 most common Tool Length Offsetting methods used on CNC milling machines, and the pros and cons of each method.Method 1 - Fo.

offset turning on cnc lathe

offset meaning in cnc programming

fixture offset cnc

The detector’s rod extensions and also the arm cuff are easily adjusted with silver colored push buttons. I was very pleased with the amount of supporting documentation that is included with the M6.

cnc machine tool offset|offset turning on cnc lathe