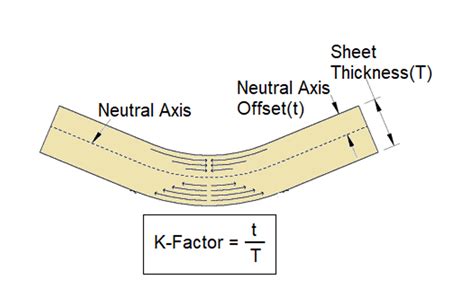

k factor in sheet metal bending is calculated by We calculate k-factor by dividing t by the material thickness (Mt): k-factor = t/Mt, The k-factor is nothing more than a multiplier that can give you an accurate value for the . Search for used steel drawer cabinets. Find Lista, Clinton, Adrian Steel, Amtekco, and VWR for sale on Machinio.

0 · k factor sheet metal chart

1 · k factor sheet metal calculator

2 · k factor for stainless steel

3 · k factor for 5052 aluminum

4 · k factor calculator excel

5 · how to calculate k factor

6 · bend allowance k factor chart

7 · 304 stainless steel k factor

Pure metal / Used as an alloy element for aluminum, lead, zinc, and other .

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the . We calculate k-factor by dividing t by the material thickness (Mt): k-factor = t/Mt, The k-factor is nothing more than a multiplier that can give you an accurate value for the .

The K-factor is the ratio of the location of the neutral axis to the material thickness for sheet metal. The neutral axis divides the cross-section into two regions — compressive and tension . Its position shifts when the sheet undergoes the .To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left. After bending the sheet, .K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness.

The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. The K Factor is calculated using the formula: \ [ K = \frac {D} {T} \] where: \ (K\) represents the K Factor, \ (D\) denotes the distance from the inside radius of the bend to the . The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending .

To enhance the readers’ understanding of basic concepts in sheet metal design calculation, the following points will be summarized and explained:. The definitions of the two bending algorithms: bend allowance and bend .Why Use Our Sheet Metal Bend Calculator? When bending sheet metal, precise calculations are crucial to achieve the desired results. Incorrect bend allowances can lead to material wastage and production delays. Our Sheet Metal Bend . An incorrect K factor can lead to inaccuracies in the fabricated parts, potentially leading to issues with assembly or the part not meeting its intended design requirements. How is the K Factor Calculated? The K factor is calculated as a ratio of the distance from the inside face of the bend to the neutral axis over the thickness of the sheet .

The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. . The K-Factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. . The K-Factor for a 180° bend is going to be meaningless because it’s tied to the Outside Setback which .

k factor sheet metal chart

Our online calculator is your go-to tool! The K factor is a crucial parameter in sheet metal bending, but it can be tricky to determine. It depends on factors like material, thickness, inner radius, and bend angle. We've created a comprehensive guide to explain the K factor, its formula, and its implications. Simply input your material . For instance, if the distance from the inside radius of the bend to the neutral bend line (D) is 5 mm and the thickness of the sheet metal (T) is 2 mm, the K Factor would be calculated as follows: \[ K = \frac{5}{2} = 2.5 \] The SkyCiv K-Factor Calculator for sheet metal is pretty straightforward and requires just a few simple inputs via the left panel, mainly: Material Thickness (T): The initial thickness of your metal sheet before the bend Inner Radius (Ri): This is the radius on the inside curve of the bend.A smaller radius implies a sharper bend What is K-Factor in Sheet Metal Bending? The k-factor is the ratio between the thickness of the metal being bent and something called the “neutral axis/line.” The neutral axis is an invisible line that splits the thickness of the metal in half and runs all the way through the part. . Later on, we will be showing the formulas necessary to .

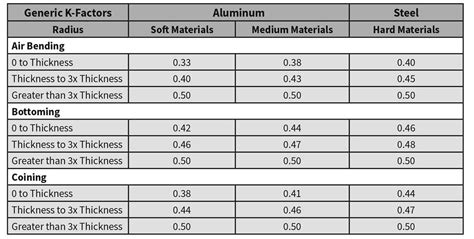

Hi I’m new to sheet metal design, can somone explain in simple terms what bend deduction, k factor is etc. and how it’s calculated? Guy who’s training me seems ignorant and rather than explain gave me a list of figures to use, he said use 4mm bend deduction for 2mm thickness, and 5.5 for 3mm thickness which is what we commonly use. In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples. SOLIDWORKS. 3D CAD . Many designers reference a chart like this or use test pieces to calculate the K-Factor for specific projects.

K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.

The K-Factor is calculated using the formula: K-Factor = (t / 2) / (t + r), where ‘t’ is the material thickness, and ‘r’ is the inside bend radius. The K-Factor value ranges from 0 to 0.5, representing different bend allowances based on the material and bending operations. Why is the K-Factor important in metal bending? The K-Factor is . Calculation of K factor for sheet metal bending. In the bending process, the outer layer of the sheet metal is subjected to tensile stress while the inner layer experiences compressive stress. Between the outer and inner layers lies a transition layer known as the neutral layer, which experiences neither tensile nor compressive stress.I'm pretty sure this isn't done and k-factor only applies to sheet metal bending, but is there an equivalent "stretch" type calculation that can be applied to tubing? I'm struggling to find good resources online describing how to deal with stretch when bending tube, probably because I don't even know what terms to use. You can accurately calculate the value of the K-factor using the following K-factor calculator: Bend Allowance Formula for Aluminum Bend allowance is a critical factor in the sheet metal bending process, particularly .

Elastic modulus (also known as Young's modulus): the greater the material thickness, the greater the K-factor. In precision sheet metal manufacturing, the K-factor is a crucial factor. The K-factor is used to calculate . The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is . Learn how the Y-Factor is used to calculate the unfolded length of a sheet metal part in bending. Discover how material type affects the Y-Factor, and how to calculate it using the K-Factor.In conclusion, the K factor plays a vital role in sheet metal bending, as it affects the calculation of bend allowance and bend deduction. By considering the material type and thickness, as well as the bend angle and inside bend radius, manufacturers can achieve precise and accurate results in sheet metal bending, ensuring that the final .

At last, when you have got the value for the Bend Allowance, you can use a formula to calculate the K-Factor. The formula, I have shared below. K Factor Calculator Formula. The K Factor Formula that is used to determine the value of the K-Factor for the available tooling, material, etc is given below: Here in this formula, BA = Bend Allowance This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical engineers, and sheet metal workers to know about the K factor. . Impact on Bending; Thickness of the sheet metal: Thicker sheets have a higher K-factor, resulting in less bending: Bend angle:

The neutral axis is a theoretical place within the sheet metal material thickness that experiences no expansion or compression. . There is another way to calculate the k-factor without bending any test pieces. It’s not perfect, but then again, neither is bending a test piece. Not only can material properties change, but so can the exact .The K-factor is essential in precision sheet metal bending, used to calculate bend allowances, bend deductions, and other parameters crucial for accurate fabrication. It represents the ratio of the neutral axis's shift to the material's thickness, expressed as K-factor = t/Mt, where t is the neutral axis shift and Mt the material thickness.K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Easily calculate the K-Factor to be used in your 3D design software. Reverse engineer the K-Factor from your own shop validated data. Find out how much tonnage will be required for .

The K-Factor is a dimensionless constant used in sheet metal bending to calculate the location of the neutral axis and ultimately predict the developed length of the flat pattern. It represents the ratio of the distance from the inside radius of the bend to the neutral bend line (R) and the thickness of the material (T). With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! This tool calculates bend allowance/deduction based on material thickness, bend angle, inside radius, and k-factor, as you will learn from the bend .

k factor sheet metal calculator

Capacities: 10' X 18 Ga Mild Steel; Sheet Metal Manual Brake For HVAC and Roofing Applications, and More; Approx. Weight: 2,000 LBS; Approx. New List Price: $6,000.00; Location: CPM Warehouse

k factor in sheet metal bending is calculated by|k factor calculator excel