rolling a cone out of sheet metal How to roll a cone on a steel slip roller. Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is compressed. There are various types of fabrication processes or techniques applied in modern production, choose the right metal fabrication method based on the material, tolerances, strength requirements, quantity, surface finish, and other factors.Metal electrical boxes are best for metal-sheathed cable or metal conduit. Weatherproof metal boxes for outdoor use are generally made of aluminum. Capable of being grounded

0 · sheet metal layout cone

1 · sheet metal cone rolling calculation

2 · sheet metal cone roller

3 · sheet metal cone development formula

4 · sheet metal cone calculator

5 · how to layout a cone

6 · cone weight calculator in kg

7 · cone layout calculator

Sheet metal fabrication is used across many industries, offering flexibility and precision in creating everything from small components to large structures. This process involves cutting, bending, and assembling metal sheets to form various products, each suited to specific needs.

Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S. Rolling a Long Cone from Sheetmetal. Ron Covell. 207K subscribers. Subscribed. 4.4K. 134K views 1 year ago. See how to roll a long cone from 16-gauge (1.6mm) sheetmetal. .more..

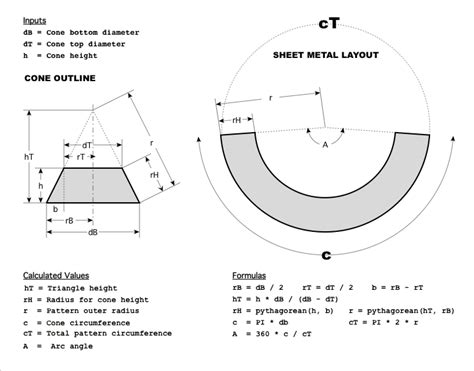

How to roll a cone on a steel slip roller. Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is compressed. Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

Rolling that cone will be a trick especially so the ends lie on the surface of the cone. There's a sheet metal trick to fix that. What is it?

The slip rollers provided by the company are engineered to provide you with astounding results irrespective of your level of proficiency to form curved cylinders or panels. Learn how to use slip rollers for perfect curves in . How to Roll a Cone Out of Sheet Metal? Have you ever wondered how complex shapes like cones and cylinders are crafted from flat metal sheets? This article explores the fascinating process of roll bending, breaking down the .

In this video I make a sheet-metal slip roll for shaping cones and cylinders. The tool I made is quite small, but yet very rigid due to the variable width design. The design can of .

Sheet metal rolling is another method of bending steel, but in this case the goal of manufacturing is to achieve a rounded circular bend, under specific radius, rather than a V-shaped angular form. Some of the main .

Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this . To lay out the flat cone: Draw an arc w/36in radius and 3.14x4in long Measure 18in from end of arc along radius and mark From center draw arc through mark to other radius . When you roll sheet metal, the spacing of the third, opposing roller determines the radius of the curve. I have misadjusted the two ends of this roller on my sheet metal .

Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted several weeks ago and you . See how to roll a long cone from 16-gauge (1.6mm) sheetmetal.You can help me create new videos by becoming a Patreon. Here’s the link:https://www.patreon.com.

Video showing the processes involved in producing a steel cone. It a job that requires a little skill and a lot of patience! About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Sheet metal is used to form these parts and they can be made through pressing or roll bending method, also known as rolling plate. The pressing method typically uses a universal die while a roll bending machine is used to perform continuous three-point bending on the plate, causing plastic deformation to achieve the required bending radius . JD goes over this BEAST of a Slip Roll and Why you want one in your garage! MORE INFO: https://www.eastwood.com/eastwood-heavy-duty-50-inch-slip-roller-with-.A Paper About Sheet Metal Cone Rolling. The cylinder and the cone can be regarded as the cylinder and the cone of the workpiece are rotated 360 degrees around the rotation centerline in the same plane. The bar of the cylindrical workpiece is parallel to the rotation center line, and the busbar and the rotation center of the cone workpiece. Tilt .

Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry. This app helps to Fabrication Engineer, Fabrication Fitter .

In California we hear “roll a cone”, and think something totally different. . Lots of math and knowledge of tool and die making but mostly it's confined by the radius and arc length of the metal sheet . This is not an official Klipper support channel and poorly moderated so ymmv. Check Klipper out on discord, discourse, or Klipper3d.org . I am using sheet metal cones in a series of bird feeders that I make. The problem is that since the apex of the cone has a small opening I have been unsuccessful rolling them with my slip roller. Consequently I have been forming them manually. . The patern of the cones are a half circle cut out of a 13" wide strip of sheet metal. So the .

A cone was formed by rolling a thin sheet of metal in a form of a sector of a circle 72 cm in diameter with a central angle of 150°. Find the volume of the cone. A. 7733 cc C. 7744 cc B. 7722 cc D. 7711 cc ZVX bending machine to roll metal sheet into a conecontact us: [email protected]

Learn how to roll sheet metal with ease using these simple steps and tips from expert inventors. Master this skill and take your metalworking projects to the. Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", .Sheet Metal Cone Rolling,Model: W12-8×2000, bending thickness 8mm, pre-bending 6mm, width effective 2100mm, top roller 210mm, PLC control, short flat ends, different shapes, smaller diameter, top crane, side supports and cone bending optional.

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at Large End, Tori Cone with knuckle radius at Both Ends . Refere Outpt Image to understand out . Rolling Techniques: A Palette of Possibilities. Sheet metal rolling machines offer a vast repertoire of techniques designed to cater to diverse applications. Whether it’s the classic 3-roll bending, where the sheet metal is shaped between three rolls, or the intricate cone rolling, where a conical shape is imparted, the versatility of these . Four roll plate bending machines are capable of satisfying the entire range of sheet metal rolling requirements and can be equipped with high levels of automation, including automatic up and down feeding devices. Disadvantage: However, the pre-curving linear segment is greater than 1.5 times the thickness of the plate.

Learn how to use a Slip Roller and form perfect sheet metal rolls.Roll sheet metal, roll cones and more with a slip roller.00:00 Intro00:24 How a Slip Roller.cone rolling machine rolling a cone sheet metal【sheet metal cone roller】sheet metal cone rolling The plate roller is a versatile machine that can be utilized to create cone-shaped pieces of metal. Rolling steel plate into cones requires careful preparation and precise execution. In this article, we will explore the process of rolling steel plate into Cut out the cone from sheet metal, and maybe slip roll to start the rolling then worked with a hammer over the horn shaped anvil. Figure to lose about .040" per cut to cut/rotate/weld for fitment. So, in other words, once you get the dyno pipes working, make the cone sections .040" long for each cut/rotate you are planing on.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

ZVS cheap rolling bending machine for turning a metal sheet into a cone Select one of the edges along the length of the cut to be the fixed edge. Now specify the desired K-factor or bend allowance. SOLIDWORKS automatically adds a sequence of features to designate the part as sheet metal to process the bends and create the flat pattern. Use the Flatten command to toggle between the flattened and rolled state.. How to make sheet metal .

sheet metal layout cone

sheet metal cone rolling calculation

A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. They are more accurate than belt drive. A Rack and Pinion system can carry more load than belt drives. They are capable of being driven very fast.

rolling a cone out of sheet metal|cone weight calculator in kg