cnc machine layout design In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your . The earliest metal milk cans are from the Island of Guernsey about 1,000 years ago, where they were made by hammering sheets of metal into a set form in the same way armor of the era was made. The design changed over time to create the standard shape you are likely to see in antique stores.

0 · machine shop tool room organization

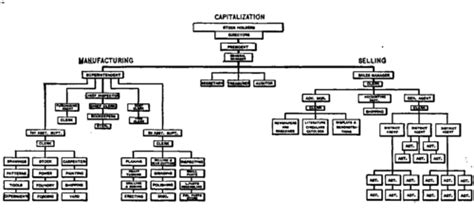

1 · machine shop organizational chart

2 · machine shop organization chart

3 · machine shop layout planner

4 · machine shop layout examples

5 · machine shop layout drawings

6 · machine shop floor plan layout

7 · lean manufacturing machine shop

In this section, we’ll explore some creative and fun real-life examples that can help middle school students understand and apply distributive property in their everyday lives. So grab a snack (or two) and let’s dive in! Mastering the distributive property: Through everyday applications! 1. Buying in bulk:

machine shop tool room organization

One crucial aspect of maximizing productivity in a CNC machine shop is the layout design. This blog post aims to provide a comprehensive guide to CNC machine shop layout drawings, .

Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface . It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different . The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials .

sheet metal fabrication sacramento ca

machine shop organizational chart

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your .

By using 3D design models to visualize your CNC machine layout, you can make sure it all fits ahead of time, and get back to cutting chips quickly. Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Designing a machine-shop’s layout will directly impact efficiency and workflow, promoting contentment among the workers and increasing productivity, for more satisfied clientele. Find the best positions for each . Setting up a new CNC machine or relocating to a new space requires thoughtful planning, especially in terms of shop layout. This guide is tailored for both new machine shop owners and existing CNC business .

A CNC machine shop’s layout can make a big difference. Find out the best ways to organize your shop for maximum work flow right here. Learn more today!

One crucial aspect of maximizing productivity in a CNC machine shop is the layout design. This blog post aims to provide a comprehensive guide to CNC machine shop layout drawings, exploring their significance, best practices, and how they can optimize workflow and efficiency.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials and personnel must cover.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. By using 3D design models to visualize your CNC machine layout, you can make sure it all fits ahead of time, and get back to cutting chips quickly.

sheet metal fabrication redlands

Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines.

Designing a machine-shop’s layout will directly impact efficiency and workflow, promoting contentment among the workers and increasing productivity, for more satisfied clientele. Find the best positions for each machine and workstation for the most optimized machine shop environment.

Setting up a new CNC machine or relocating to a new space requires thoughtful planning, especially in terms of shop layout. This guide is tailored for both new machine shop owners and existing CNC business owners facing a move.

A CNC machine shop’s layout can make a big difference. Find out the best ways to organize your shop for maximum work flow right here. Learn more today!One crucial aspect of maximizing productivity in a CNC machine shop is the layout design. This blog post aims to provide a comprehensive guide to CNC machine shop layout drawings, exploring their significance, best practices, and how they can optimize workflow and efficiency.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials and personnel must cover.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining.

By using 3D design models to visualize your CNC machine layout, you can make sure it all fits ahead of time, and get back to cutting chips quickly. Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Designing a machine-shop’s layout will directly impact efficiency and workflow, promoting contentment among the workers and increasing productivity, for more satisfied clientele. Find the best positions for each machine and workstation for the most optimized machine shop environment.

machine shop organization chart

Pros of metal door frames: Environmentally friendly, since no trees are used to manufacture them. Cons of metal door frames: Choosing the material for your door frame is as important as choosing your door. Learn the pros and cons of metal door frames here.

cnc machine layout design|machine shop layout planner