3 axs cnc milling machine Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike. Find Weatherproof junction boxes at Lowe's today. Shop junction boxes and a variety of electrical products online at Lowes.com.

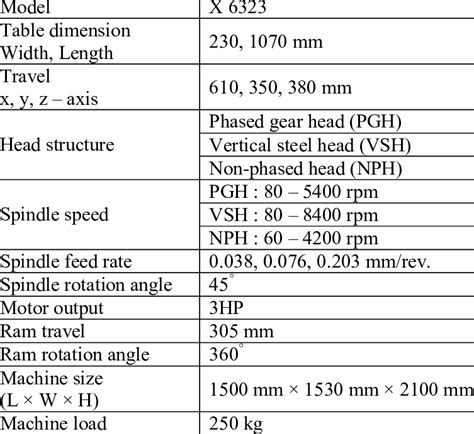

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

Metal is highly susceptible to thermal bridging making it more costly to design or insulate properly and with r-values increasing for residential properties it simply is not the best use of the material.

A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances.The VM Series 3-axis CNC machining centers are designed for job shops that need high performance in limited space. Featuring the powerful WinMax control system, these machines cater to both conversational users and G-code programmers, offering flexibility for .The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level.

With an energy-efficient design, a DATRON CNC mill consumes less than 2.7kW on average. The smallest 3-axis machine, the neo, is available as a single-phase, making it easy to plug in just about anywhere.In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.3-axis milling machinery features three main axes (X, Y, and Z) to create components, perform hole drilling, or sharpen product edges. As their name implies, 4-axis and 5-axis milling add additional axes to their fabrication systems, allowing for advanced rotational movement and multidimensional processing.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.

A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances.The VM Series 3-axis CNC machining centers are designed for job shops that need high performance in limited space. Featuring the powerful WinMax control system, these machines cater to both conversational users and G-code programmers, offering flexibility for .The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level.

With an energy-efficient design, a DATRON CNC mill consumes less than 2.7kW on average. The smallest 3-axis machine, the neo, is available as a single-phase, making it easy to plug in just about anywhere.In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.

steel cooler box

specifications of cnc milling machine

steel divers sub wars game box

small 3 axis cnc mill

If you have a grounded conduit going in to a metal box (no ground wires), do you need to attach a grounding pigtail to the metal box and then to the outlet ground screw? Or is .

3 axs cnc milling machine|3 axis cnc machine price