creating a curved sheet metal part in solidworks A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern. Make . There are different sheet metal welding techniques, but do you know which is best for your industrial applications? This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications.

0 · sheet metal bending in SolidWorks

1 · curved cylinder in SolidWorks

2 · SolidWorks sheet metal round bend

3 · SolidWorks sheet metal flange

4 · SolidWorks sheet metal edge flange

5 · SolidWorks sheet metal cylinder

6 · SolidWorks sheet metal curved bend

7 · SolidWorks fold sheet metal

This article covers everything you need to know about welding thin sheet metal: from tips for beginners to advanced welding techniques that experienced professionals use under difficult circumstances.

Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, .Base flange/tab lets you do native sheet metal parts with no flat sections. Standard models without flat sections can be converted to sheet metal using .

A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern. Make .You can sketch an ellipse and a create sheet metal part that has elliptical bends. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet .This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command ( GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend ). When creating a sheet metal part in SOLIDWORKS, one of the key features is the capability to “Flatten” the model into a sheet so it can be manufactured. This allows the manufacturing entity to have a flat pattern .

When bending sheet metal, you can create round bends instead of sharp bends. The Insert Bends feature also allows you to create rips. Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can .

sheet metal bending in SolidWorks

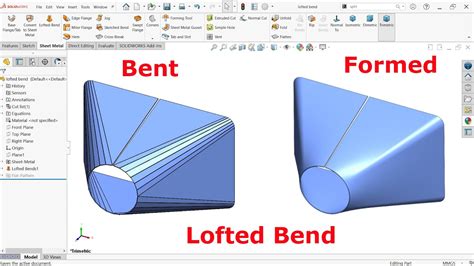

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .Bends in the sheet metal module must be sections of a cylinder. Not true, you can achieve more complex bends using the lofted bend tool. However, you cannot create a compound bended . Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities.

Base flange/tab lets you do native sheet metal parts with no flat sections. Standard models without flat sections can be converted to sheet metal using "insert bends" with a straight edge as the fixed entity.

curved cylinder in SolidWorks

A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern. Make sure your sketch is fully defined and that straight entities are tangent to arcs.You can sketch an ellipse and a create sheet metal part that has elliptical bends. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create a configuration in a sheet metal part that shows the flattened part.

This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command ( GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend ).

When creating a sheet metal part in SOLIDWORKS, one of the key features is the capability to “Flatten” the model into a sheet so it can be manufactured. This allows the manufacturing entity to have a flat pattern drawing derived from the created part.When bending sheet metal, you can create round bends instead of sharp bends. The Insert Bends feature also allows you to create rips. Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or .

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the Insert Bends feature. 3. Use the Convert to Sheet Metal feature. When using the Insert Bends or Convert to Sheet Metal features, apply the features as early Bends in the sheet metal module must be sections of a cylinder. Not true, you can achieve more complex bends using the lofted bend tool. However, you cannot create a compound bended surface, i.e. one that curves in 2 directions at once. Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

cnc machining steel parts suppliers

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities. Base flange/tab lets you do native sheet metal parts with no flat sections. Standard models without flat sections can be converted to sheet metal using "insert bends" with a straight edge as the fixed entity.

A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern. Make sure your sketch is fully defined and that straight entities are tangent to arcs.You can sketch an ellipse and a create sheet metal part that has elliptical bends. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create a configuration in a sheet metal part that shows the flattened part. This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command ( GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend ).

When creating a sheet metal part in SOLIDWORKS, one of the key features is the capability to “Flatten” the model into a sheet so it can be manufactured. This allows the manufacturing entity to have a flat pattern drawing derived from the created part.When bending sheet metal, you can create round bends instead of sharp bends. The Insert Bends feature also allows you to create rips. Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the Insert Bends feature. 3. Use the Convert to Sheet Metal feature. When using the Insert Bends or Convert to Sheet Metal features, apply the features as early

cnc machining steel pipe

SolidWorks sheet metal round bend

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and characteristics.

creating a curved sheet metal part in solidworks|sheet metal bending in SolidWorks