blanking in sheet metal In sheet metal blanking operation, the cut material is a finished part and the . Explore & source all the CNC replacement parts you need to keep your machine in top working order. Connect with us if you need help finding the correct part.

0 · sheet metal flat length calculation

1 · semi piercing in sheet metal

2 · perforating operation in sheet metal

3 · how to calculate blanking force

4 · difference between shearing and blanking

5 · difference between blanking and stamping

6 · blank size calculator sheet metal

7 · blank length calculator

Your aluminum machined parts manufacturer providing cost-effective solutions for CNC machined lightweight components.

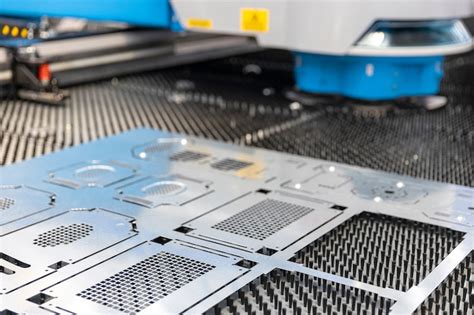

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. In this article, we will discuss how blanking punching, and piercing operations are different .In sheet metal blanking operation, the cut material is a finished part and the .

Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and . From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. .

Dive into the intricacies of sheet metal blanking, from its pivotal role in manufacturing to tips for entrepreneurs and emerging trends.Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the .

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of . In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find .

Piercing, punching, and blanking are crucial processes in sheet metal fabrication, and understanding the differences is essential for achieving precise and efficient operations. .

Sheet metal blanking is a vital metalworking process that shapes thin metal sheets into precise tolerances for numerous applications. From material selection to finishing .Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. In this article, we will discuss how blanking punching, and piercing operations are different from one another. What Is Sheet Metal Blanking? In sheet metal blanking, you will use punch and die system to extract suitable part from a large sheet metal. The extracted piece is the blank and one machine operation can blank multiple sheets simultaneously. Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and construction, .

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.

electric horse box

sheet metal flat length calculation

Dive into the intricacies of sheet metal blanking, from its pivotal role in manufacturing to tips for entrepreneurs and emerging trends.Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the blanking process that are essential for achieving high precision in sheet metal products. Read on to unlock more!

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find all information right here. Piercing, punching, and blanking are crucial processes in sheet metal fabrication, and understanding the differences is essential for achieving precise and efficient operations. The processes offer several benefits, including high precision, dimensional accuracy, surface quality, and cost efficiency.

Sheet metal blanking is a vital metalworking process that shapes thin metal sheets into precise tolerances for numerous applications. From material selection to finishing operations, each phase of the blanking process plays an important role in producing quality parts while minimizing waste.

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. In this article, we will discuss how blanking punching, and piercing operations are different from one another. What Is Sheet Metal Blanking? In sheet metal blanking, you will use punch and die system to extract suitable part from a large sheet metal. The extracted piece is the blank and one machine operation can blank multiple sheets simultaneously. Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and construction, .

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.Dive into the intricacies of sheet metal blanking, from its pivotal role in manufacturing to tips for entrepreneurs and emerging trends.

Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components. In this ultimate guide, you will discover the 6 key steps in the blanking process that are essential for achieving high precision in sheet metal products. Read on to unlock more!

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find all information right here.

semi piercing in sheet metal

Piercing, punching, and blanking are crucial processes in sheet metal fabrication, and understanding the differences is essential for achieving precise and efficient operations. The processes offer several benefits, including high precision, dimensional accuracy, surface quality, and cost efficiency.

electric hot water heater electric shut off box

Shop online for wholesale cnc machine part? Global Sources has a full-scale list of wholesale cnc machine part products at factory prices featured by verified wholesalers & manufacturers from China, India, Korea, and other countries to satisfy all the requirements!

blanking in sheet metal|perforating operation in sheet metal