why use a metallic junction box Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic .

Conduit Junction Box; Brand: Tripac Cabac Tripac DJB1-20 Deep Conduit Junction Box, Round, 20mm 1Way, PVC, Grey

0 · where are junction boxes located

1 · when to use junction box

2 · residential junction box

3 · junction box vs receptacle

4 · junction box for electrical wiring

5 · function of junction box

6 · different types of junction boxes

7 · are junction boxes safe

UVAIR Solutions Better disinfection performance: From lamps to electronics to installation ease and safety, the UVS-Series is designed to deliver unsur - passed performance. Indoor air as healthy as the great outdoors. Ultravation web site

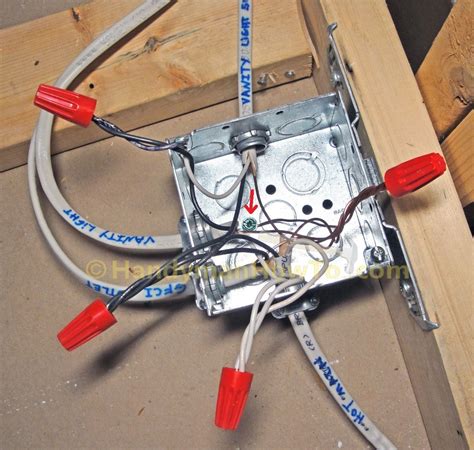

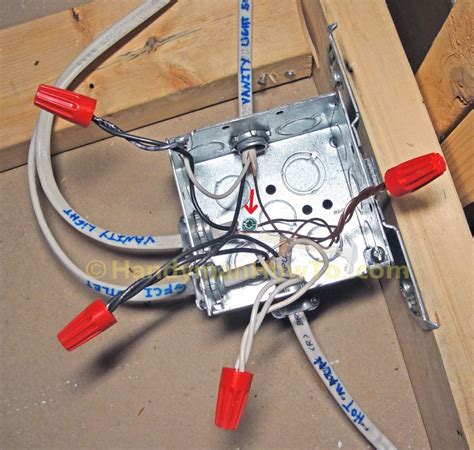

Strong, fireproof, and incapable of melting, metal boxes offer the greatest level of security for all electrical wiring applications. Compared to plastic boxes, metal electrical boxes are very strong: It is virtually impossible to bend, warp, twist, or crush metal electrical or junction .15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .

Going under alternative names such as metallic sheathed cable, type AC, MC, .To install this type of clamp, insert the threaded end into a knockout hole in the . Therefore, we use metallic junction boxes in areas with a high risk of environmental and electrical damage. You may also use metal for an outdoor junction box. They are not affordable, like plastic junction boxes; however, .

Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic . In use for far longer than PVC versions, metal electrical boxes are super-strong, fireproof, and incapable of melting. They offer the greatest level of security for electrical wiring applications . It's also virtually impossible to crush . Junction boxes can be made of either metal or plastic. Plastic junction boxes are typically more affordable and easier to handle. However, it is important to note that certain plastic junction boxes may not offer the same . Metal junction boxes offer durability and grounding capabilities, making them suitable for outdoor and industrial applications. Plastic junction boxes are lightweight and .

Discover the pros and cons of plastic vs metal junction boxes. Learn which is better for your electrical projects based on durability, safety, and cost. Metal boxes are fireproof, strong, do not melt, warp, crack, crush, or bend, and provide excellent security for various electrical wiring applications. Local building codes in .

All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayhomerepairs Do you feel comfortable using metal electrical boxes on your DIY elect. Exception No. 2: Where integral bonding means with a provision for attaching an equipment bonding jumper inside the box are provided between all threaded entries in nonmetallic boxes listed for the purpose, nonmetallic boxes shall be permitted to be used with metal raceways or metal-armored cables. Can you use a metallic cover on a plastic box? The scenario I'm thinking of would be a weatherproof plastic box with GFI's and a metallic in use cover. My thinking is that there would be a bonding issue with the cover. I don't have a cover in front of me. I suppose if the GFI mounts to the cover it would be bonded. But to code?

The use of plastic electrical boxes on metal studs can generally be allowed, but it is advisable to consult your local code enforcement regulations for specific guidelines. Should junction boxes be metal or plastic? Junction boxes can be made of either metal or plastic. Plastic junction boxes are typically more affordable and easier to handle. Why use boxes at all? Oh, right. Okay, if we're using boxes for actual reasons, then every single reason to use a box is better served by a metal box. Plastic boxes are designed to install 10 seconds faster - which only benefits builders. –

Metal conduit and junction boxes outside MUST be grounded for the same reason even low voltage cable must be, it gives static from things like wind a place to go instead of building up and creating a lightning rod (which is a misnomer as a real lightning rod prevents the strike by giving the static an earth/ground path that’s safe). According to this video from homedepot.com and this page from thisoldhouse.com I can use a standard metallic threaded cable connector like this one The thisoldhouse.com page also mentions using Romex from the inside through the wall to the box outside.Plastic is cheaper and probably more easier to work with (don’t need to ground the box), but it flexes more - if it’s for myself I’d probably use the metal and make sure it gets solidly mounted so that it doesn’t flex when you insert/unplug cables - but also like others have said, use single or double gang boxes, not these octagon boxes

where are junction boxes located

Then, remove the existing junction box cover and wiring. Next, install the new junction box according to the instructions. Once the box is in place, secure the fan wiring to the box, then cover the box and restore the power. Types of Ceiling Fan Junction Boxes. There are two main types of ceiling fan junction boxes available: plastic and metal .Please re read my post. I am using an LB on the outside. This metal box is to be mounted inside connecting to the LB using conduit acting as the junction box. Hence why I am asking how to mount it to studs..z

canadian electrical raceways floor boxes

Metal junction boxes are one of the most common types of electrical boxes used in residential and commercial installations. These boxes are typically made of steel or aluminum and offer excellent durability and protection. They are often used in areas where there is a higher risk of physical damage or exposure to moisture, such as basements . Consider the type of electrical cable you are using, too. If the project calls for non-metallic cable, such as Type NM-B (non-metallic sheathed cable), you can use plastic boxes or metal boxes. If you are installing wires enclosed in metal conduit, you must use a metal box. Also, determine whether you need an old work or new work electrical box.

Either move the GFCI to the position before this one, or use a bigger box as Jim Port suggests. Jim is referring to 4x4 boxes with screws on the corners, plus a 1-gang domed cover. Do not try to "2-gang" GFCIs in a 4x4 box, you'll have the same problem as the Handy-Box. Use 4-11/16" boxes for that, which have the breathing room.314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding additional raceways. . If it's listed as a junction box and it's made of metal, according to the NEC it has to have a tapped hole or equivalent for the . Step 3: Attach the Grounding Wire to the Metal Junction Box. If you are using screws, insert the screw into the pre-drilled hole in the junction box and tighten it until snug. Then, attach the grounding wire to the screw. If you . A short demonstration of how to install and attach an electrical ground clip to a metal junction box.

Use a wire nut to secure the connection and don’t forget that there should be a wire that is connected to the grounding screw. How to Tell if the Metal Box Is Grounded? A lot of homeowners might not know if their metal box is already . As we are learning to install a quality electrical product during our apprenticeships, we are constantly reminded to bond our metallic boxes. But why do we b. I reside in CT - Anyone know if I can run my indoor Romex wire through house wall into a metal junction box? From there I'll run Schedule 40 with THHN wire out to endpoints. Core question here is - Can I run Romex through house wall into waterproof junction box mounted on outside wall and still fall within code? Thanks in advance. That’s why it’s so important for junction boxes to be well-designed and have the right performance specs. Electrical junction boxes made from durable, high-grade plastics are increasingly popular. What are the common pros and cons that electrical designers and contractors should be aware of when choosing whether to use plastic junction boxes?

In certain situations, using a metal junction box is not just a good idea but necessary. For Metallic-Sheathed Wires and High-Stress Installations: Metal boxes are a must if you’re working with metallic-sheathed wires, also known as BX cable. These boxes provide grounding, which is essential for safety. .Metal boxes are compatible with metal clad wires. Metal boxes have better shallow options and can easily be combined to make multigang options not available in plastic. Plastic boxes are cheaper and faster to work with but not so much so that it's worth an extra trip to a supply house. Commercial work there is no choice. We use metal boxes.

Gang Junction Box. There are different types of gang junction boxes, from 4-gang, 3-gang, and 2-gang versions. They all have similar structure and are fabricated using metal. Gang junction boxes are ideal as indoor electrical boxes, and you can employ 2-gang versions all through to 4-gang boxes. Outdoor Junction Boxes

If you use a junction box, it has clamps that put pressure on all the wires coming into it. That reduces the chances of the splice pulling apart. But, just in case it does, and the wires become exposed, the box is grounded. So, the live wires will hit that grounded box and the wire will see a near 0 ohm connection to ground, which will . Keep in mind NEC 2014 has new rules broadly allowing grounds to be retrofit by running appropriate sized ground wires from any junction box to the panel, another junction box that has adequate size ground (or non-flex metal conduit back to the same panel, or the bare copper wires of the Grounding Electrode System (can't be cut, you use a split .

when to use junction box

Re: GROUND SCREWS IN METAL JUNCTION BOXES With metal boxes and metal conduit, 250.146 (A) (B) and (C) allows some devices to be installed with out a wire grounding jumper. In my area, we mostly use metal conduit and grounding is done a great deal of the time with listed self grounding devices, and no jumper.

residential junction box

$11.99

why use a metallic junction box|are junction boxes safe