what is sheet metal operations Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions. This black and gold oval wall mirror with brackets adds style and depth to any living space. This artfully crafted mirror showcases a sleek black metal frame with contrasting gold-finished wall brackets that create a stunning visual effect. The mirror is made of metal, glass, and reclaimed wood for a durable and stylish look.Tru-Duct, Inc. is a family owned and operated sheet metal fabrication company. Since it’s founding in 2001, Tru-Duct has become one of the largest sheet metal fabricators in Southern California. Drew Miles, owner and founder, attributes the company’s success to his and his .

0 · types of bending sheet metal

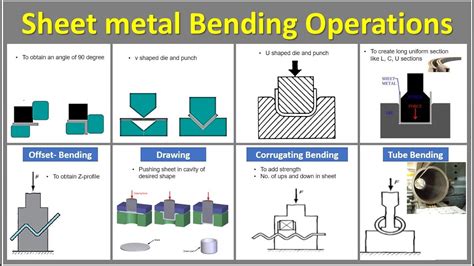

1 · sheet metal operations with diagrams

2 · sheet metal operations pdf

3 · perforating operation in sheet metal

4 · parting operation in sheet metal

5 · name various sheet metal operations

6 · forming operation in sheet metal

7 · drawing operation in sheet metal

Septic System Distribution Box Review and Setup Tuf-Tite Distribution Box Setup y Review Tuf-Tite 4 Hole Distribution Box with fitting (For 4 inch Pipe)Discr.

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, .

Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions.

Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.

Punching Blanking and piercing are sheet metal shearing operations to shape the sheet metal parts using a pneumatic or hydraulic press. Sheet metal drawing, a crucial manufacturing process, stands as a cornerstone in the creation of hollow, multifaceted components with a sharp focus on precision. This technique is instrumental in the production of a diverse .SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. . Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet .

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the . Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped, or other complex-curved, hollow parts. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity.

Sheet Metal Engineering Operations and Techniques. There are several techniques are approved in the market that are involved in custom sheet metal engineering. Most of these techniques combine different tech tools to . Hi Friends,In this video you will learn Different types of Cutting operation in sheet metal | Sheet metal cutting operationsShearingCutoff Parting offBlankin.The term is used because most sheet metal operations are performed on presses. The three basic sheet metalworking operations are. bending, drawing, and shearing. What makes shearing different from the other two operations? Shearing involves cutting of sheet metal, whereas the other two operations do not.

The sheet metal operation in which we remove certain parts of the sheet metal from the bigger part is known as blanking. The removed or punched out part takes the shape of the die by which it got punched and it is the useful part. Simply put, cutting operations cause the sheet metal to be stressed beyond its final/very best strength, therefore, breaking its structure and separating into different parts. Shearing is the process of separating the sheet metal into two or more pieces, (usually/ is a common and regular way) by cutting along a line. Commonly used to cut into .Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. The shearing operation in sheet metal fabrication involves a setup that aligns the metal sheets correctly and allows for uniform pressure distribution across the cutting area. Mechanics of Metal Shearing. The mechanics behind metal shearing primarily involve the role of the blades and cutting edges. The shear blades have specific angles and .

hensel electric box

Nibbling Operation in Sheet Metal The nibbling operation is a cornerstone in sheet metal fabrication, especially when detailed, intricate cuts are required. Unlike traditional cutting, where a large part of the material is removed at once, nibbling is a gradual process, ensuring a higher degree of precision and material integrity.Sheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Various special tools are used in this process to convert sheet metals into useful components by minimal efforts. It is a value-added process to create machines, structures, or component parts following engineering drawings which usually serves as the .

Below are the tools used in sheet and other metal fabrication processes to carry out operations like shearing, blanking, shaping, punching, etc. . Sheet Metal Forming Tools. Shrinker stretchers: It is one of the most used and common forming tools, used to shape materials. The operation does not require the need of heating, cutting, or welding .

Many sheet metal cutting operations are based on computer numerically controlled (CNC) laser cutting or multi-tool CNC punch press. CNC laser involves moving a lens assembly carrying a beam of laser light over the surface of the metal. Oxygen, nitrogen or air is fed through the same nozzle from which the laser beam exits.

hensel junction box pdf

Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal. Although the technique is suitable for most grinding operations in sheet metal fabrication, the grinding wheel degrades faster. Additionally, the length is limited and the process may require more power. In the current sheet .What is Sheet Metal Processing?. At the heart of numerous industries, sheet metal processing stands as a foundational practice that allows for the creation of myriad products, tools, and structures. But what exactly does the term entail? . #sscje #mechanical #gearinstitute Click here to download our apphttps://edumartin.page.link/jLFrJoin telegram channelhttps://t.me/gearinstituteJE की .

शीट मेटल में प्रयोग होने वाली धातुएं. Sheet Metal Use In Hindi : जैसा कि हम सब जानते हैं शीट मेटल अलग-अलग उपकरण वस्तुओं को बनाने के लिए इस्तेमाल की जाती है लेकिन सभी . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few. Keep reading to learn more.Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. .

types of bending sheet metal

A sheet metal stamping process is a metalworking process carried out at room temperature wherein parts are both cut and shaped from a parent metal strip or. . How is more than one cutting operation accomplished in the sheet metal stamping process? More than one distinct operation can be accomplished in a stamping die. Two cutting operations .Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine. A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees. Thinner sheets are easier to turn.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped, or other complex-curved, hollow parts. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. The estimated total pay for a Sheet Metal Operations Manager is ,955 per year, with an average salary of ,318 per year. These numbers represent the median, which is the midpoint of the ranges from our proprietary Total Pay Estimate model and based on salaries collected from our users. The estimated additional pay is ,637 per year. Punching, a common sheet metal cutting operation, involves the use of a punch and die to create holes or cut out shapes from the metal sheet. Punching operation is highly efficient for creating repetitive patterns or shapes. Applications of Punching in Sheet Metal Cutting: Commonly used for creating holes, slots, or shapes in metal sheets. #sscje #mechanical #gearinstitute Click here to download our apphttps://edumartin.page.link/jLFrJoin telegram channelhttps://t.me/gearinstituteJE की .

sheet metal operations with diagrams

herramientas para torno cnc

CNC Tube Benders Manufactured by Hines Bending. Hines CNC tube bending machines– 3-axis- are computer numerically controllable (CNC) and servo-driven for distance between bends (DBB), plane of bend (POB) and degree of bend (DOB).

what is sheet metal operations|types of bending sheet metal