bend sheet metal 90 degrees They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent . Need a drawing or design ? We can help. Custom dollies and tables made per your specs. Custom Water Tanks small or large. Custom flashing or downspouts for the roofing industry. Maintenance repair for dozens of local companies. .

0 · sheet metal bending strength

1 · sheet metal bending drawing

2 · sheet metal bending diagram

3 · sheet metal bending chart

4 · sheet metal bending angle chart

5 · radius of regular 90 bend

6 · large radius sheet metal bending

7 · calculate bend radius sheet metal

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent .

In this guide, we will explore the step-by-step process of bending sheet metal 90 degrees, including the tools you will need, the different types of bends you can make, and some helpful tips to ensure you get the perfect bend .

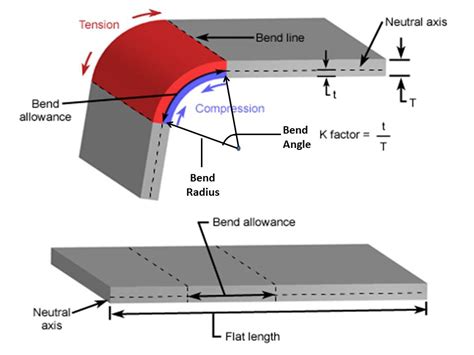

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with 90 degrees bend which is the most simple scenario. Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees. We will start by calculating the Bend Allowance. From there we can calculate the .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

sheet metal bending strength

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent to 160 degrees complementary. In this guide, we will explore the step-by-step process of bending sheet metal 90 degrees, including the tools you will need, the different types of bends you can make, and some helpful tips to ensure you get the perfect bend every time.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with 90 degrees bend which is the most simple scenario. Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees. We will start by calculating the Bend Allowance. From there we can calculate the K-Factor and the Bend Deduction. After bending the sheet we need to do some measurements as shown in Figure 2. To achieve a 90-degree bend, you must overbend the material past the desired bend angle and allow it to return to the desired shape with the springback. Figure 1 shows perhaps one of the simplest die designs that can achieve a 90-degree bend. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now.

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece.

quality sheet metal and welding factory

They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent to 160 degrees complementary. In this guide, we will explore the step-by-step process of bending sheet metal 90 degrees, including the tools you will need, the different types of bends you can make, and some helpful tips to ensure you get the perfect bend every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

quaser cnc machines

Let’s start with 90 degrees bend which is the most simple scenario. Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees. We will start by calculating the Bend Allowance. From there we can calculate the K-Factor and the Bend Deduction. After bending the sheet we need to do some measurements as shown in Figure 2.

sheet metal bending drawing

sheet metal bending diagram

Our catalogs include Non-metallic Junction Box, Wall Plate, GFCI, Switch, etc. With years of experience exploring the industry, we've got the ETL/UL Certificate and passed the 2 Hour Fire Resistance Test with 19 invention patents.

bend sheet metal 90 degrees|sheet metal bending chart