sheet metal working operations However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what . At 1stDibs, there are several options of vintage doll houses available for sale. Each of these unique vintage doll houses was constructed with extraordinary care, often using fabric, wool .

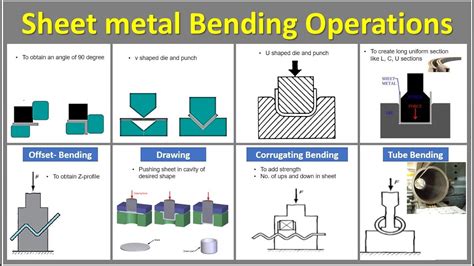

0 · types of bending sheet metal

1 · sheet metal operations with diagrams

2 · sheet metal operations pdf

3 · perforating operation in sheet metal

4 · parting operation in sheet metal

5 · name various sheet metal operations

6 · forming operation in sheet metal

7 · drawing operation in sheet metal

$12.99

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. There are a large variety of processes with subtle differences that .SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. . Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions. What is it exactly? How does it work? And most importantly, how can it benefit your business or project? This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need .

types of bending sheet metal

There are various types of sheet metal operations for making products. Some basic operations list is below. Blanking. Punching. Piercing. Cut-off. Parting off. Notching. Bending. Let we will discuss the types of sheet metal operations in .Sheet Metalworking. Cutting and forming operations performed on relatively thin sheets of metal which are produced by rolling. Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) . SHEET METAL WORKING OPERATIONS AND APPLICATIONS

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations, In conventional sheet metalworking operations (a). what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet metal part, is the clearance applied to the punch diameter or the . Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually . Which working methods of sheet metal presses to choose will vary depending on specific application requirements. So, let’s have a look at them. Sheet Metal Cutting Operations: Sheet metal cutting operations are essential processes in metalworking, where press operation in sheet metal is subjected to various stresses to achieve precise cuts .Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. . an operation is performed on a work piece during a stroke of the press. 40. THANK YOU 4. Sheet Metal Working Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Operations usually performed as cold workingProgressive Work and Tool & Die Design. Progressive stamping is a metal forming process that uses a series of dies to create complex parts from sheet metal. The sheet metal is fed into the press by a coil or strip, and each die station performs a different operation on the metal, such as cutting, bending, punching, or drawing.

Sheet metal forming is commonplace in a variety of industries and everyday items. Read on to find out everything you need to know about sheet metal forming, how it works, and where it’s used. . This process adds a hollow circular roll to the edge of the sheet metal it’s working on to smooth them out, improve safety when handling, and add . Sheet Metal Operations, Blanking, Notching, Drawing, Punching, Perforating, Nibbling, Bending, Embossing

Sheet metal cutting operations involves the separation of metal piece from larger sheet by shearing forces of the punch and die. . Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us .

In sheet metal work, various operations such as shearing, blanking, piercing, trimming, shaving, notching, forming, bending, stamping, coining, embossing etc. are to be performed on sheet metal using hand tools and press machines to make a product of desired shape and size. Generally metals used in sheet metal work are black iron, galvanized . 3. 1.0 Introduction Sheet metal is simply metal formed into thin and flat pieces. Sheet metal is essentially metal pressed into sheets. These sheets are used at various places. These sheets can be bent, cut and molded into any shape for use anywhere. Sheet metal is generally produced in sheets by reducing the thickness of work piece by compressive forces . 7. 5: Notching: This is cutting operation by which metal pieces are cut from the edge of the sheet , strip or blank. 6: Perforating: This is a process by which multiple holes are very small and close together are cut in a flat sheet metal. 7: Slitting: It refers to the operation of making incomplete holes in a work piece. 8: Lancing: This is a cutting operation in which a .

Hot Rolled Steel: Steel created via several rolling operations at temperatures more than 1700 degrees Fahrenheit is referred to as hot-rolled steel. Because of their malleability, steels of this kind may be readily shaped . Study with Quizlet and memorize flashcards containing terms like The three basic types of sheet metalworking operations are (1) cutting, (2) bending, and (3) drawing., The die diameter equals the blank diameter, and the punch diameter is smaller by twice the clearance., In V-bending, a simple punch and die that each have the included angle are used to bend the .The term is used because most sheet metal operations are performed on presses. The three basic sheet metalworking operations are. bending, drawing, and shearing. . This is a compression process in which the work metal is forced to fl ow through a die opening, thereby taking the shape of the opening as its own cross section. .Study with Quizlet and memorize flashcards containing terms like Sheet metal working includes both forming and cutting operations. true or false, most sheet metal working operations are performed as a)cold working b)hot working c)warm working, in a sheet metal cutting operation used to produce a flat part with a hole in the center, the part itself is called a blank, and the .

The document discusses various sheet metal press working operations like cutting, bending, forming, drawing, blanking, piercing, flanging, and notching. It provides the theory, terminology, and design considerations for these operations. Key operations covered include blanking, bending, cylindrical cup drawing, rectangular shell drawing, and irregular shape drawing. .One of the simplest types of press working operations is a sheet metal cutting process called a straight cutoff. A punch separates a length of stock along a straight line. Industrial sheet metal cutting operations such as this will usually incline the punch so as to reduce the maximum force needed by distributing the required force over the .Study with Quizlet and memorize flashcards containing terms like 1. Sheet metalworking includes both forming and cutting operations: (a) True or (b) false?, 2. Typical sheet-metal thicknesses are between 0.4 mm (1/64 in) and 6 mm (1/4 in). When thickness exceeds the upper limit of this range, the stock is usually referred to as which one of the following: (a) bulk stock, (b) .In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) . Stretch forming of sheet metal consists of simultaneously stretching and bending the sheet-metal work part to achieve shape change. Identify the principal components of a stamping die that performs blanking.

Like ductile metals, the ductile materials are rolled or hammered into a thin sheet in some special cases. This property of the material is known as Malleability.So, malleability is the property of the material that gives an identity of sheet metal. the sheet metal or malleable material should be plastic but it is not compulsory to be so strong.Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .

It defines press working as a chipless manufacturing process that uses a press machine to form sheet metal components by applying force. It then describes common sheet metal cutting operations like blanking, punching, trimming, shaving, notching, and shearing. Forming operations like bending and embossing are also summarized. The document aims . Introduction • Cutting operations are very important part of sheet metal working. • Cutting is used I. to separate large sheets into smaller pieces II. to cut out a part perimeter. III. to make holes in a part • The tooling used to perform cutting operation is called a punch and a die. • They are perform on machine tools called presses.

sheet metal operations with diagrams

Sheet metal operations are cold-working processes that can manufacture low-cost metal parts in high volumes quickly. Sheet metal is metal between 0.006-0.25 inches thick that can be cut, bent, or stretched into various shapes. Common sheet metal operations include embossing to add raised or sunken designs using heat and pressure, coining to add .

sheet metal operations pdf

perforating operation in sheet metal

rustic houses with metal roofs

$1,944.00

sheet metal working operations|parting operation in sheet metal