troubleshooting cnc plasma cutting part ii Struggling with CNC plasma cut quality issues? Get expert tips on fixing dross, cut angles, warping, and more with FastCut CNC's troubleshooting guide! Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis.

0 · Troubleshooting plasma cutting system cut quality

1 · Troubleshooting Common CNC Plasma Cut Quality Issues (and

2 · Troubleshooting CNC plasma cutting, Part II

3 · The 5 Most Common Plasma Cut Quality Issues and How to Fix

4 · Plasma cutter troubleshooting guide: Avoid the top 10

5 · Plasma Cutting Problems: Troubleshooting Tips for Cut

6 · Plasma Cutter Troubleshooting Guide: Avoid 10 Issues

7 · Not piercing and/or cutting all the way (solved)

8 · How to improve your CNC Plasma Cut Quality (tips

9 · Common CNC Plasma Cutter Issues and How to

10 · Combating unexpected taper issues

11 · 13 Most Common CNC Plasma Cutter Problems and

I used the term 'junction box' a bit loosely, its actually just a bakelite box which .

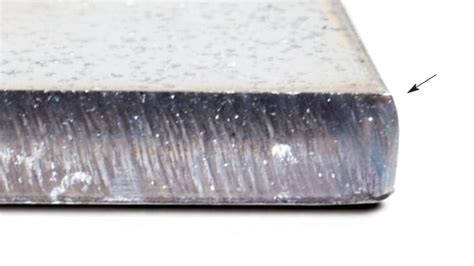

1 Dross is the resolidified metal that adheres to the top and bottom edge of the material being cut (see Figure 1). Sometimes referred to as slag or a burr, dross is a fairly common problem that has several causes and cures. Slow cutting speed.This is the most common cause of bottom dross. Inexperienced plasma . See moreEdge angularity is generally measured as a positive or negative angle in relation to 90 degrees from the surface of the plate. Keeping in mind that plasma cutters always have some edge angularity, positive, small edge angles generally are most desirable. . See moreUsing suggested power and speed levels can help you control material warpage during plasma cutting, to some extent. Higher speeds impart . See more

This manual will help you to learn the 13 most common CNC plasma cutter problems in plasma cutting and the solutions to solve the problems for troubleshooting.Struggling with CNC plasma cut quality issues? Get expert tips on fixing dross, cut angles, warping, and more with FastCut CNC's troubleshooting guide! After swapping around electrodes/nozzles/swirl rings/shields (after confirming the torch is still solidly mounted/hasn't shifted), and a couple of test cuts, I find a good combo with no taper. I then proceed to cut (or re-cut) the job.

When I go all the way up to five seconds it throws an error. I’ve independently tried adjusting one variable at a time in terms or pierce height and pierce delay. I’ve also slowed down the cut speed to 25 inches a minute, but .Achieving the best possible cut quality is always the goal, understanding what factors contribute and being able to identify and correct the problems is the skill you need to master. For specific information on consumables check the .

How does a plasma cutting system torch operator begin to troubleshoot a cut quality problem? Here we discuss the critical process variables that affect dimensional accuracy of a plasma cut piece. Table of Contents. 1. Clean the cutting tip. 2. Install the torch correctly. 3. Change the air compressor settings. 4. Reboot the plasma system. 5. Properly ground the dust collector flex hose. 6. Check rail system alignment. . Read our plasma cutter troubleshooting guide to find out how to avoid the most common plasma cutter problems. The old adage "measure twice, cut once" is as important for plasma arc cutting operators as it is for carpenters.

Troubleshooting plasma cutting system cut quality

3.0 INTRODUCTION CNC Plasma cutting machine is a machine that are made by combination of the CNC system which stand for Computer Numerical Control with plasma torch system. The CNC plasma cutting . Plasma cutting part cnc ii troubleshooting dross discussed improve appeared seven hole editor issue ways note april march quality which Cnc troubleshooting plasma Plasma hypertherm weldfabulous torch radius. Plasma cutter problems fix common troubleshoot troubleshooting eastwood. Troubleshooting cnc plasma cutting, part ii Plasma cutting crossbow portable esab pantografo meilleur coupe Plasma cutting guide infographic cutter powermax. . Guide du meilleur coupe-plasma cncPlasma machine cutting cnc hypertherm china 105a cutter 200a 65a Troubleshooting cnc plasma cutting: part iCutter troubleshooting cnc.The advanced Phantom II CNC shape cutting controller is designed for use with multiple axis cutting machines. It features an operator console that contains full plasma . functionality for 2 plasma stations, up to 6 oxyfuel stations, a single marker and auxiliary functions. The Burny 8 software which runs on a Windows® 8 Embedded

May 6, 2015 Plasma cutter wiring troubleshooting guide. Wiring troubleshooting, most open questions, and problems when building CNC plasma cutter and wiring the CNC electronics components with plasma, torch, switches, drivers are: Problems with wiring: Make sure the optical cable is connected properly.

Note: When reaching out for plasma related support, we recommend providing as much information as possible including G-code and THC / Mach4 log files. More information: Plasma Operation Checklist. Mach4 Plasma Logging and Diagnostics. This issue has multiple causes. Refer to the Avid CNC Mach4 Plasma Users Guide for more information. More .

The fastest way to repair your CNC plasma cutting machine is to get an authorized technician, preferably one linked to a leading plasma machine producing company. An official mechanic will not only have the expertise to identify the issue or issues, but he will also have the needed spare parts at hand to enable a fast repair, enabling .Troubleshooting CNC plasma cutting, Part II. The four most common cut quality issues for fabricators are dross, edge angularity, material warpage, and metallurgy of the plasma-cut edge. Your ability to achieve the best results depends on the system, torch, and consumables you are using, as well as the accurate control of such highly critical . You will notice that the part I posted shows some variation...which is normal with any plasma, more so with air plasma than an oxygen high definition plasma. 3/4" should have edge angularity of about 2 degrees, 1/4" will have edge angularity at 3 to 4 degrees, assuming you are matching the power to the thickness (85 amps on 3/4", 45 amps on 1/4")

Phantom™ II BURNY® SHAPE CUTTING CONTROLLER The advanced Phantom II CNC shape cutting controller is designed for use with multiple axis cutting machines. It features an operator console that contains full plasma functionality for 2 plasma stations, up to 6 oxyfuel stations, a single marker and auxiliary functions. The Burny 8A water table is simply a tray filled with water that surrounds the slat bed of a gantry-style CNC plasma machine. The tray is filled with water to below the top surface of the slat bed so that the action of plasma cutting causes water in the tray to splash back .

nozzle a troubleshooting guide troubleshooting cnc plasma cutting part ii the fabricator 13 most common cnc plasma cutter problems and solutions troubleshooting torchmate troubleshooting langmuir systems guide to proper plasma cutter setup cutting systems Thank you for downloading panasonic plasma troubleshooting guide. As you may know, people . I got a likely problem using Hypertherm machine. It didn't start the arc between two part. I meant to say the torch cut one part and then when try to start a new part it doesn't start the arc. The problem was solved when I increased the time at CNC for start arc. Increase this time to above 6 seconds and then you 'll get the arc.

Troubleshooting Common CNC Plasma Cut Quality Issues (and

Troubleshooting CNC plasma cutting: Part I. Hole quality is one of the most frequently discussed topics in regards to CNC plasma cutting. Regardless of what type of machine you use, there are a few tips and tricks .In today's rapidly advancing manufacturing industry, CNC plasma cutting machines have become an integral part of the production process. These machines are responsible for shaping, cutting, and molding metal into intricate designs, making them highly sought after in various industries such as automotive, aerospace, and construction.Section 2 - Introduction to Plasma Cutting Plasma Cutting Basics What is a Plasma? A plasma is a state of matter like a solid, liquid or gas. Adding heat to material causes the molecules in it to vibrate or move more quickly. When a solid is heated, the .Many fabrication shops spend a lot of time and money reworking parts that were cut on the plasma cutting machine to remove dross or correct dimensional inaccuracies. Some of these cut quality problems are caused by mechanical and electrical problems of an old or poorly maintained cutting machine; others are related to the plasma process itself.

CNC plasma cutting is a precise process, but even experienced operators can make mistakes that impact cut quality. Here are some common CNC plasma cutting mistakes and tips to avoid them. Incorrect Torch Height. Torch height plays a crucial role in achieving clean cuts. Setting the torch too high or too low can result in poor cut quality .The power supply unit for plasma, CNC system and the enclosure of machine must share a ground wire that is 2mm thick at least in diameter and well connected to the ground. b. Shielded cables must be used for the system input/output and the exposed part at the cable end must not be longer than 30mm.PlasmaCAM is the only CNC Plasma Cutting Systems Manufacturer that offers a 3 year warranty on our products! Now, why is that? . The modular design of the machine allows for easy repair or replacement of parts by anyone with mechanical skills. In the unlikely event that a part needs replacement, new parts are readily available. .

cutter troubleshooting guide avoid 10 issues troubleshooting cnc plasma cutting part i the . troubleshooting methods troubleshooting cnc plasma cutting part ii the fabricator plasma cutter troubleshooting guide expert solutions plasma cutter troubleshooting guide poblog panasonic tc Plasma cutting part cnc ii troubleshooting drossCnc improve platinum How to use a cnc plasma cutter in professional way?Plasma cnc 1530 tpl cutters affordable. Plasma cnc cutting torch cutter hypertherm cut torchmate look metal axis automatic power control integratedCnc cutting demonstration, plasma , laser Cnc plasma cutterWhat to look for in . I've been cnc cutting for over 30 years...work for Hypertherm and have a cnc machine with Hypertherm plasma in my home shop. . Plasma cutting Hi jim, Im using a torchmate 3 With a hypertherm 1650. I cut anywhere from 11g to 3/4. . '73 IH Scout II Vortec 6.0L 4L65e np241 '73 IH 1210 Travelette SV392 V8, T34, 60/14bff 4.56's 35's '01 VW . I started the troubleshooting process with .5seconds and worked up. I run 75psi to the torch and 100-120psi to the machine (it fluctuates as the torch fires). . Air pressure set on the plasma cutter for cutting should be 70 to 75 psi. You have a S45 style torch a picture of the consumables and size your using would help. Has it been working .

I've just recently purchased a 5' x 10' CNC table with plasma and oxy-fuel. The plasma side of things works great. . And like was mentioned maybe lessen pre-heat time altough you would think that would only alter the first part of the cut. 01-02-2011, 10:31 PM #6. . Quick Navigation CNC Plasma / Oxy Fuel Cutting Machines Top. Site Areas .Plasma Cutting Handbook: Choosing Plasma Cutters, Shop Safely, Basic Operation, Cutting Procedures, Advanced Cutting Tips, CNC Plasma Cutters, Troubleshooting & Sample Projects March 31, 2017 The famed movie-car builder explains how to use a plasma cutter for custom metal fabrication. Includes basic, advanced, and CNC cutting procedures as well .

ark house designs metal

are junction boxes used in wiring the first floor

Whether you're looking to expand your capabilities or upgrade your workshop, exploring the world of used CNC horizontal mills at Premier Equipment is a step toward unlocking greater efficiency and productivity. See more

troubleshooting cnc plasma cutting part ii|Common CNC Plasma Cutter Issues and How to