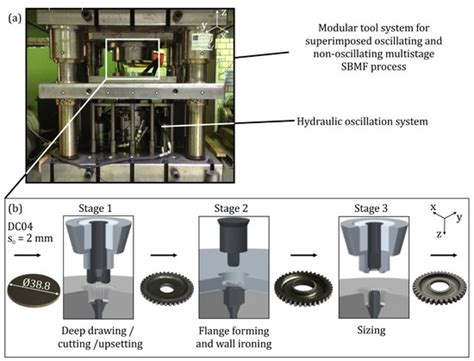

overview on sheet-bulk metal forming processes This paper presents also the experimental forming tests that verified these forming techniques and provided a thickness profile that reduces maximum thinning and forming times .

The Expandable Weldable Metal Sheets are great for replacing old barbecue surfaces, cages, and screens. Use in the farm house, workhouse or garden. Available in several sizes, choose the one that best fits your needs.

0 · sheet metal forming process

1 · bulk sheet metal forming

This white Combi 1010 empty enclosure has been designed for extreme conditions both indoors and out. It consists of strong thermoplastic housing made from two separate plastic components with unique design ribbed corners and .

By applying bulk forming processes to sheet metal material the TCRC 73 is providing a significant contribution to the development of forming technologies and thus to the solution of several of . SBMF unites the advantages of sheet and bulk metal forming processes. Cold forging has among others the advantages of strain hardening during the forming process, high .

The process class sheet-bulk metal forming (SBMF) provides the manufacturing of local functional features in the magnitude of the sheet thickness through a controlled material .During the forming process of the incoming metal sheets, bars, plates, tubes or powder, the material is plastically deformed by a force to obtain the required size and shape, as well as the . The paper defines this new class of sheet-bulk metal forming processes, gives an overview of the existing processes belonging to this class, highlights the tooling aspects as . This paper presents also the experimental forming tests that verified these forming techniques and provided a thickness profile that reduces maximum thinning and forming times .

The paper gives an overview on the application of sheet-bulk metal forming operations in both scientific and industrial environment. Beginning with the need for an innovative forming .

In sheet-bulk metal forming processes, the bulk deformation of sheet is carried out that invariably brings out the intended changes in the thickness as well. Some examples of bulk metal .

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . Sheet-bulk metal forming (SBMF) processes are defined as sheet metal forming where the flow occurs in three dimensions similar to bulk metal forming . The main characteristic of these processes is that the final product . Sheet-bulk metal forming (SBMF) processes are defined as sheet metal forming where the flow occurs in three dimensions similar to bulk metal forming . The main characteristic of these processes is that the final product .

The paper gives an overview on the application of sheet-bulk metal forming operations in both scientific and industrial environment. Beginning with the need for an innovative forming technology .Forming of shallow parts using rubber tools. Maziar Ramezani, Zaidi M. Ripin, in Rubber-Pad Forming Processes, 2012. 4.1 Introduction. Sheet metal forming is a costly manufacturing process that is widely used in different industries. Many small companies are required to manufacture curved products and shallow parts with fine details in a small lot size which leads to both a .

The paper defines this new class of sheet-bulk metal forming processes, gives an overview of the existing processes belonging to this class, . In order to make the definition more precise, additional information on sheet-bulk metal forming processes as well as its features will be given: The class of sheet-bulk metal forming processes .

Introduction. Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and the specific techniques employed.Study the fundamentals related to design and manufacturing of metallic products by Bulk and Sheet metal forming methods. . This course provides a comprehensive overview of the different types of deformation processes used in metal forming, including bulk deformation techniques such as rolling, forging, extrusion, and wire drawing, as well as .

Introduction: An Overview on Bulk Metal Forming Processes Introduction The broad topic of bulk metal forming includes many processes both as classical and modified categories. These classical bulk metal forming processes are still in great demand in many industry sectors. It does not seem that this trend will slowBulk Metal Forming Rolling - compression process to reduce the thickness of a slab by a pair of rolls. Forging - compression process performing between a set of opposing dies. Extrusion - compression process sqeezing metal flow a die opening. Drawing - pulling a wire or bar through a .

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies. (DOI: 10.26634/jfet.17.3.18775) The massive shaping processes (forging, rolling, extrusion, wire and bar drawing) play an important role to fabricate metal products. These forming processes undergo plastic deformations of the metal and acquire required shapes and sizes by application of suitable stresses such as tension, compression and shear. Thus due to the .

sheet metal forming process

The current state of research is reviewed to provide an overview of process combinations and the resulting interactions. Furthermore, opportunities and challenges for the investigated process sequences are derived. . [81] the additive process is used to produce a tailored blank, which is then formed in a sheet-bulk metal forming process to .Bulk forming processes are a group of manufacturing methods that involve shaping and forming metals and materials through the application of compressive forces. These processes are typically used to create components that are larger in size and exhibit a significant change in shape.Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required. Categories: Bulk . 2. BULK DEFORMATION PROCESSES: Metal forming operations which cause significant shape change by deformation in metal parts whose initial form is bulk rather than sheet. These processes work by stressing metal .

Overview of Non-Bulk Products. Sheet metal forming used for products like car/truck bodies, aircraft fuselage, trailers, office furniture, and more. Dates back to 5000 B.C. with household utensils and jewelry made from gold, silver, and copper. Offers versatile shapes, light weight, and high stiffness-to-weight ratio compared to casting or .The massive shaping processes (forging, rolling, extrusion, wire and bar drawing) play an important role to fabricate metal products. These forming processes undergo plastic deformations of the metal and acquire required shapes and sizes by application of suitable stresses such as tension, compression and shear. Thus due to the characteristics such as cost effectiveness, .Metal Forming Processes Metal forming processes include bulk forming and sheet metal forming with numerous applications. This book covers some of the latest developments aspects of these processes such as numerical sim-ulations to achieve optimum combination and to get insight into process capability. Implementation Metal forming processes are used to shape metals into useful products. Rolling is the most common forming process and accounts for around 90% of metal forming. It involves passing metal between rolls to reduce thickness or change cross-section. Forging uses dies and compression to shape hot or cold metal.

The massive shaping processes (forging, rolling, extrusion, wire and bar drawing) play an important role to fabricate metal products. These forming processes undergo plastic deformations of the metal and acquire required shapes and sizes by application of suitable stresses such as tension, compression and shear. Thus due to the characteristics such as cost effectiveness, . Summary. The Bulk & Sheet Forming Processes for Manufacturing Engineers course is a great way for students to learn about the different metal forming processes used in manufacturing. The course covers a wide range of topics, including rolling, forging, extrusion, wire drawing, and sheet metal working. Students will learn the fundamental concepts behind these . Frederiksen and Wanheim [1] used friction-testing methods based on the geometrical changes in order to adjust the frictional conditions in the simulation to the condition of the real process. Bay [2] studied the application of the friction model when analyses of bulk metal forming process are given. In addition to measuring of friction with general methods like ring .

cnc machine metal companies

An Overview Of Metal Forming Process. August 12, 2021 | In Industry News & Blog . Metal forming processes are broadly divided into Bulk metal forming and Sheet metal forming processes. Forging (open die forging, impression die forging, press forging), swaging, radial forging, roll forging, extrusion, ‘wire, rod, and tube’ drawing, and . Due to rising demands regarding the functionality and load-bearing capacity of functional components such as synchronizer rings in gear systems, conventional forming operations are reaching their limits with respect to formability and efficiency. One way to meet these challenges is the application of the innovative process class of sheet-bulk metal forming .Bulk Metal Forming. Bulk forming processes such as forging, extrusion and rolling are key processes of modern industrial manufacturing. Especially for structural components and safety-critical applications, forming components are essential due to their reliable mechanical properties. . Overview. LKR Leichtmetallkompetenz- zentrum Ranshofen .

Study with Quizlet and memorize flashcards containing terms like Describe the similarities and the differences between the bulk deformation processes described in chapter 6 and sheet-metal forming processes described in this chapter, As a practicing engineer in manufacturing, why would you be interested in manufacturing, why would you be interested in the shape of the .

cnc machine mold making

As we dive deeper into the CNC history timeline, one name stands out – John T. Parsons. Many consider Parsons to be the father of modern CNC. The initial concept of numerical control machining started to form when Parsons was granted a contract in 1949 to construct helicopter rotor blades.

overview on sheet-bulk metal forming processes|sheet metal forming process