dinking process in sheet metal Explore the three primary shearing processes (shearing, blanking, punching) utilised by the metalworking industry along with their subprocesses and unique characteristics. Shearing Operation Working Principle. $16.98

0 · what is dinking metal

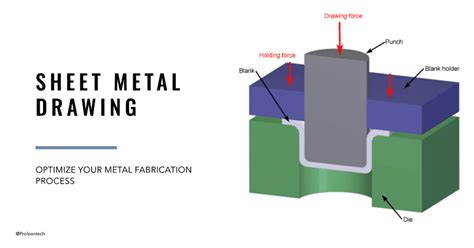

1 · sheet metal process

2 · sheet metal drawing process

3 · sheet metal design process

4 · sheet metal cutting process

5 · sheet metal blanking process

6 · sheet metal blanking

7 · deep drawing of sheet metal

Is It Okay To Cover a Utility Box? 1. Gorgeous Plant Combination by Backyard Neophyte. 2. Hide Those Utility Boxes with a Gorgeous Garden. 3. Rustic Garden Hideaway for Utility Boxes. 4. Bright and Fun Utility Box Cover. 5. Hide It With Hydrangeas and Wood. 6. DIY Lattice Screen for Utility Boxes. 7.

Dinking: This is a method that cuts out small and irregular shapes from sheet metal, such as washers, gaskets, or buttons. It uses a hand-operated tool called a dinking machine, which .

Rubber Pad Forming (RPF) RPF is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and . Explore the three primary shearing processes (shearing, blanking, punching) utilised by the metalworking industry along with their subprocesses and unique characteristics. Shearing Operation Working Principle.Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fibre, foil, cloth, paper, corrugated fibreboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal. In the metalworking and leather industries, the process is known as clicking and the machine may be referred to as a clicking machine. When a dinking die or .• Dinking is a modified shearing operation that is used to blank shapes from low-strength materials, primarily rubber, fiber, and cloth. II. Bending . III. Drawing. at the uniform elongation .

Sheet metal processes involve plane stress loadings and lower forces than bulk forming • Almost all sheet metal forming is considered to be secondary processing • The main categories of sheet metal forming are: • . Stamping Includes a variety of operations, such as punching, blanking, embossing, bending, flanging, and coining; simple or complex shapes formed at high production rates; tooling and equipment costs can be high, but .

Sheet Metal Forming Involves methods in which sheet metal is cut into required dimensions and shape; and/or forming by stamping, drawing, or pressing to the final shape Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. .

•Sheet metal processes involve plane stress loadings and lower forces than bulk forming •Almost all sheet metal forming is considered to be secondary processing •The main categories of sheet metal forming are: –Shearing –Bending –Drawing

Dinking: This is a method that cuts out small and irregular shapes from sheet metal, such as washers, gaskets, or buttons. It uses a hand-operated tool called a dinking machine, which has a sharp steel punch and a rubber pad. Rubber Pad Forming (RPF) RPF is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. Explore the three primary shearing processes (shearing, blanking, punching) utilised by the metalworking industry along with their subprocesses and unique characteristics. Shearing Operation Working Principle.

Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fibre, foil, cloth, paper, corrugated fibreboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal.• Dinking is a modified shearing operation that is used to blank shapes from low-strength materials, primarily rubber, fiber, and cloth. II. Bending . III. Drawing. at the uniform elongation region. In sheet materials, material properties usually change with rolling directions. IV. Shapes other than Cylindrical Cups. Sheet metal processes involve plane stress loadings and lower forces than bulk forming • Almost all sheet metal forming is considered to be secondary processing • The main categories of sheet metal forming are: • Shearing • Bending • Drawing 17.1 Introduction Stamping Includes a variety of operations, such as punching, blanking, embossing, bending, flanging, and coining; simple or complex shapes formed at high production rates; tooling and equipment costs can be high, but labor costs are low.

Sheet Metal Forming Involves methods in which sheet metal is cut into required dimensions and shape; and/or forming by stamping, drawing, or pressing to the final shape Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. 2. Deep drawing uses a die and punch to shape flat sheets into cup-shaped parts.•Sheet metal processes involve plane stress loadings and lower forces than bulk forming •Almost all sheet metal forming is considered to be secondary processing •The main categories of sheet metal forming are: –Shearing –Bending –DrawingDinking: This is a method that cuts out small and irregular shapes from sheet metal, such as washers, gaskets, or buttons. It uses a hand-operated tool called a dinking machine, which has a sharp steel punch and a rubber pad.

Rubber Pad Forming (RPF) RPF is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. Explore the three primary shearing processes (shearing, blanking, punching) utilised by the metalworking industry along with their subprocesses and unique characteristics. Shearing Operation Working Principle.

Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fibre, foil, cloth, paper, corrugated fibreboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal.• Dinking is a modified shearing operation that is used to blank shapes from low-strength materials, primarily rubber, fiber, and cloth. II. Bending . III. Drawing. at the uniform elongation region. In sheet materials, material properties usually change with rolling directions. IV. Shapes other than Cylindrical Cups. Sheet metal processes involve plane stress loadings and lower forces than bulk forming • Almost all sheet metal forming is considered to be secondary processing • The main categories of sheet metal forming are: • Shearing • Bending • Drawing 17.1 Introduction Stamping Includes a variety of operations, such as punching, blanking, embossing, bending, flanging, and coining; simple or complex shapes formed at high production rates; tooling and equipment costs can be high, but labor costs are low.

Sheet Metal Forming Involves methods in which sheet metal is cut into required dimensions and shape; and/or forming by stamping, drawing, or pressing to the final shape

what is dinking metal

garage metal roof sheets

$34.99

dinking process in sheet metal|sheet metal design process