3-axis cnc milling machines Applications: cone cleaning, tool data monitoring, safe withdrawal movement, . Most load centers (that I am aware of) allow 2 or 3 #14 or #12 EGCs per hole. As I recall, SquareD allows 2, CH allows 3. You just need to check the panel itself. It is usually located on the chart that shows the various torque values.

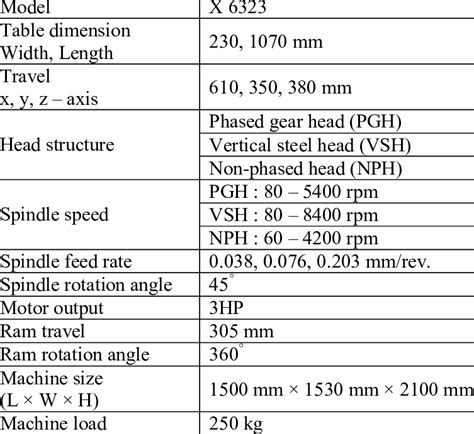

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

type ‘b’ cast iron frame, grate & vertical inlet details for nos. 10, 12, 14, 16 & 17 type .

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table .Applications: cone cleaning, tool data monitoring, safe withdrawal movement, .Z-axis drop prevention function, ideal for blackouts; Oil cooler (separate type) .The NVD4000 DCG focuses on advanced CNC control, high-precision positioning, .

The NVD 5000 α1 focuses on advanced CNC control, high-precision positioning, .Machine size : 61.3 × 128.9 × 104.3 in. Mass of machine: .

Highest precision, rigidity as well as maximum flexibility in the field 3-axis .Applications: cone cleaning, tool data monitoring, safe withdrawal movement, .The monoBLOCK series has a machine concept for every sector: Be it 5-axis .

3-axes or 5-axes machining with B-axis and integrated NC table Spindle versions .Universal machining center for 5-axis machining. These 5-axis machines with .

Need help finding the right machine? A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC .Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.The VM Series 3-axis CNC machining centers are designed for job shops that need high performance in limited space. Featuring the powerful WinMax control system, these machines cater to both conversational users and G-code .

In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because .These German-engineered CNC mills are versatile enough to keep up with your prototyping, industrial production, and precision machining needs. With an energy-efficient design, a DATRON CNC mill consumes less than 2.7kW on .Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.

Need help finding the right machine? A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.The VM Series 3-axis CNC machining centers are designed for job shops that need high performance in limited space. Featuring the powerful WinMax control system, these machines cater to both conversational users and G-code programmers, offering flexibility for .In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.

These German-engineered CNC mills are versatile enough to keep up with your prototyping, industrial production, and precision machining needs. With an energy-efficient design, a DATRON CNC mill consumes less than 2.7kW on average. The smallest 3-axis machine, the neo, is available as a single-phase, making it easy to plug in just about anywhere.

The high-speed milling solution that set the standard for performance and precision. The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge .Our high-performance line of 3-axis mills, the VMX Series is where expert design and advanced technology meet . These CNC machining centers deliver high-performance capabilities to any machining application.

Clausing CNC Knee Mill, 3 axis (column) Fanuc Oi-MF or Delta NC50E-FE control, 49" Long x 9" wide Table, 5Hp spindle motor, BT30 spindle taper. . The Clausing 2KV30CNC Vertical Milling Machine delivers a powerful, versatile, and precise solution for modern machining needs. Built for efficiency and enhanced performance, this CNC mill features .While relatively simplistic in relation to 4-axis and 5-axis milling, 3-axis CNC milling still provides an effective solution for precision machined parts. Miller CNC performs superior 3-axis machining services to meet or exceed your expectations.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.

specifications of cnc milling machine

Need help finding the right machine? A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Tormach 1100M - Compact 3-Axis CNC mill with PathPilot controller and is Ideal for one-offs, short-run production, rapid prototyping, secondary operations, and educational institutions alike.The VM Series 3-axis CNC machining centers are designed for job shops that need high performance in limited space. Featuring the powerful WinMax control system, these machines cater to both conversational users and G-code programmers, offering flexibility for .

In their simplest design, milling machines are set up for 3-axis machining: the tool moves over the workpiece in the X, Y and Z direction. A rotary axis, in the headstock or the table for example, extends the range of machining because components can also be positioned at an angle.

These German-engineered CNC mills are versatile enough to keep up with your prototyping, industrial production, and precision machining needs. With an energy-efficient design, a DATRON CNC mill consumes less than 2.7kW on average. The smallest 3-axis machine, the neo, is available as a single-phase, making it easy to plug in just about anywhere.The high-speed milling solution that set the standard for performance and precision. The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge .Our high-performance line of 3-axis mills, the VMX Series is where expert design and advanced technology meet . These CNC machining centers deliver high-performance capabilities to any machining application.Clausing CNC Knee Mill, 3 axis (column) Fanuc Oi-MF or Delta NC50E-FE control, 49" Long x 9" wide Table, 5Hp spindle motor, BT30 spindle taper. . The Clausing 2KV30CNC Vertical Milling Machine delivers a powerful, versatile, and precise solution for modern machining needs. Built for efficiency and enhanced performance, this CNC mill features .

where to get sheet metal near me

where is smart junction box on ranger

Now you get to face me!, in a Twisted Metal fight to death!

3-axis cnc milling machines|axis identification in cnc machine