12 axis cnc machine diagram There are three main components to multiaxis machines: The machines physical . The best way to weld galvanized steel, regardless of welding process, is to remove the zinc coating from the joint. This adds two operations: removing the coating and re-spraying or painting the weld seam after welding to regain corrosion resistance.

0 · rotating x axis machine

1 · multi axis machining process

2 · multi axis cnc machines

3 · mill xyz axis

4 · cnc axis explained

5 · axis identification in cnc machine

6 · 12 axis cnc mill

7 · 12 axis cnc machine price

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

Thanks to the features of the machine: - Double productivity (comparing with the conventional single head cnc working centers) - Possibility to machine from the bottom to the top thanks to the.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various . There are three main components to multiaxis machines: The machines physical .

From 3-axis to 12-axis CNC milling: Learn how different axes impact production capabilities and choose the right machine for your project.

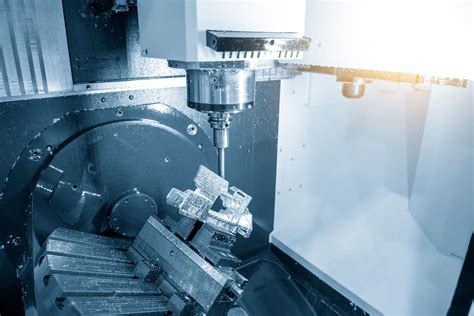

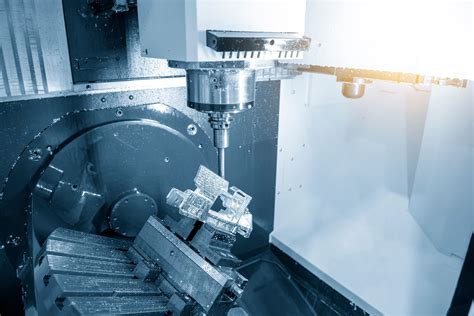

– Axis Mechanisms: CNC machines can have multiple axes of motion, typically referred to as X, Y, and Z axes for three-dimensional machining. Each axis is equipped with linear guides, ball screws, and other mechanisms . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .Common CNC routers typically have 3 to 5 axes, but there are also advanced machines with up to 12 axes. Whether you are looking to take production in-house or source custom CNC parts for your next project, it’s worth .

Clear diagrams with key components is marked out and explained. The available accessories and tools are reviewed. Next the control software is explained, how it works and the minimum .A computer numerical control (CNC) system, showcasing the block diagram of cnc machine, consists of three basic components: CNC software which is a program of instructions, a machine control unit, and processing equipment, .In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

Thanks to the features of the machine: - Double productivity (comparing with the conventional single head cnc working centers) - Possibility to machine from the bottom to the top thanks to the. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.From 3-axis to 12-axis CNC milling: Learn how different axes impact production capabilities and choose the right machine for your project.

– Axis Mechanisms: CNC machines can have multiple axes of motion, typically referred to as X, Y, and Z axes for three-dimensional machining. Each axis is equipped with linear guides, ball screws, and other mechanisms to control . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This .

rotating x axis machine

Common CNC routers typically have 3 to 5 axes, but there are also advanced machines with up to 12 axes. Whether you are looking to take production in-house or source custom CNC parts for your next project, it’s worth understanding which machines are capable of .Clear diagrams with key components is marked out and explained. The available accessories and tools are reviewed. Next the control software is explained, how it works and the minimum features needed to know. This is followed by a quick introduction of the CAD/CAM software.A computer numerical control (CNC) system, showcasing the block diagram of cnc machine, consists of three basic components: CNC software which is a program of instructions, a machine control unit, and processing equipment, also called machine tool.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

cnc cutting machine factories

Thanks to the features of the machine: - Double productivity (comparing with the conventional single head cnc working centers) - Possibility to machine from the bottom to the top thanks to the. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.

cnc custom machining surrey

multi axis machining process

From 3-axis to 12-axis CNC milling: Learn how different axes impact production capabilities and choose the right machine for your project. – Axis Mechanisms: CNC machines can have multiple axes of motion, typically referred to as X, Y, and Z axes for three-dimensional machining. Each axis is equipped with linear guides, ball screws, and other mechanisms to control . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This .

Common CNC routers typically have 3 to 5 axes, but there are also advanced machines with up to 12 axes. Whether you are looking to take production in-house or source custom CNC parts for your next project, it’s worth understanding which machines are capable of .

Clear diagrams with key components is marked out and explained. The available accessories and tools are reviewed. Next the control software is explained, how it works and the minimum features needed to know. This is followed by a quick introduction of the CAD/CAM software.

multi axis cnc machines

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results.

12 axis cnc machine diagram|mill xyz axis