sheet metal fabrication formlabs Formlabs is proud to announce Form 4L, our next-generation large-format resin 3D printer that takes the speed, accuracy, and reliability of Form 4 to a completely new scale. Learn More. .

The Wright Foam Cube is constructed of 32 shore hardness foam and wrapped in a Heavy Duty 20oz Vinyl shell. With indicator marks easily showing the height setting. This foam box weighs 55LBS which allows for safe storage and moving around your box.

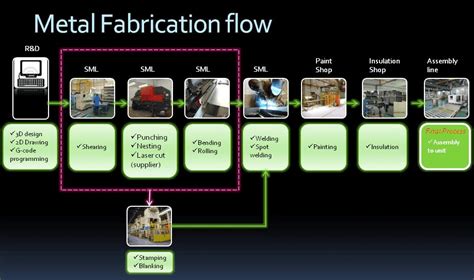

0 · sheet metal manufacturing process

1 · sheet metal forming tools

2 · sheet metal forming techniques

3 · sheet metal forming machine

4 · sheet metal forming cost

5 · sheet metal forming

6 · sheet metal formation process

7 · how does sheet metal forming work

Buy RegulatorFix Window Regulator Repair Clip Bracket Metal (1) w/Spacer (1) - Rear (Left or Right) Compatible with BMW 5 Series E39: Clips - Amazon.com FREE DELIVERY possible on eligible purchases

In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies. For a .In this white paper, learn how engineers can leverage the speed and flexibility of .

Formlabs is proud to announce Form 4L, our next-generation large-format resin .In this white paper, learn how engineers can leverage the speed and flexibility of 3D printing without the expense of direct metal printers by using metal casting workflows, including .

Combine 3D printed rapid tooling with traditional manufacturing processes to produce limited quantities of parts in common plastics, silicones, rubbers, composites, or metals, with a flexible, agile, scalable, and cost-efficient tooling .Formlabs is proud to announce Form 4L, our next-generation large-format resin 3D printer that takes the speed, accuracy, and reliability of Form 4 to a completely new scale. Learn More. .

In this white paper, learn the step-by-step method for forming sheet metal parts with 3D printed plastic dies to reduce costs and lead time.In this webinar, Shane Wighton, engineering lead at Formlabs, will teach you how to form sheet metal with SLA 3D printed tools. Learn specific design considerations and application .

The sheet metal forming process is straightforward: 1 . A sheet of metal is cut out from a stock metal to create individual blanks . 2 . The blank is placed in the forming machine in between .

Sheet Metal Fabrication. From easy quoting to quick-turn production and finishing options, get up to 500 quality sheet metal parts in your hands in days from a single supplier. Learn More3D printing is a powerful tool and Formlabs resin 3D printers make it easy to start printing. By adding advanced techniques to your 3D print process, you can expand what it’s possible to .Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and .The sheet metal forming process is straightforward: 1 . A sheet of metal is cut out from a stock metal to create individual blanks . 2 . The blank is placed in the forming machine in between two tools . 3 . Subjected to the high forces of the machine, the upper tool pushes the sheet metal around the matching lower tool and bends it in the .

Join Formlabs if you want to bring groundbreaking professional 3D printers to the desktop of every designer, engineer, researcher, and artist in the world. . Are familiar with a variety of manufacturing techniques including injection molding and sheet metal fabrication;

bleach steel box collection

sheet metal manufacturing process

0 (0 die + sheet metal stock) 0 (0 die + sheet metal stock) Outsourced metal tool: Pressing machine, metal cutting equipment: 25 business days: 0 (0 die + sheet metal stock) 0 (0 die + sheet metal stock) Outsourced metal part: None - fully outsourced: 15 business days: 0: 0Those familiar with rapid prototyping may find themselves asking about the differences between rapid prototyping and rapid tooling.. Rapid prototyping is the group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. Because these parts or assemblies are usually constructed using additive .

Typically in FRP fabrication, the continuous straight fibers are joined in the matrix to form individual plies, which are laminated layer-by-layer onto the final part. . thermoforming or sheet metal forming to deliver low-volume batches. . Additionally, the Formlabs Resin Library has engineering materials with mechanical and thermal .Join us to explore how The Factory Amsterdam (TFA), a CNC Machine Shop focused on automation, leverages Formlabs SLS technology to gain flexibility and adapt faster to customer needs. After an overview of the step-by-step method, our guest speaker will share practical examples with cost analysis, design considerations, and best practices to 3D .Fabrication. Basic model making and fabrication are similar in approach, but the latter makes use of power tools and superior materials to create prototypes that are stronger, more accurate, and include functional aspects. . Materials range from easy-to-assemble modular systems like 80/20® aluminum extrusions, to sheet metal, plastic, and .

3D printing is a powerful tool and Formlabs resin 3D printers make it easy to start printing. By adding advanced techniques to your 3D print process, you can expand what it’s possible to create. From finishing to assemblies to fabrication, advanced 3D printing techniques open up possibilities for 3D printed molds, electroplating, surface textures, fittings, prints larger than .

Xometry offers a wide selection of metal and plastic materials with various finishes and post-processing options. These high-performance materials are matched to an extensive list of manufacturing capabilities from CNC machining to sheet metal fabrication, to 3D printing, to plastic injection molding and urethane casting to meet the specific requirements of your projects.Typically in FRP fabrication, the continuous straight fibers are joined in the matrix to form individual plies, which are laminated layer-by-layer onto the final part. . thermoforming or sheet metal forming to deliver low-volume batches. . Additionally, the Formlabs Resin Library has engineering materials with mechanical and thermal . In sheet metal fabrication CAD software offers advanced features such as automatic gauge adjustment, . (Source: formlabs.com) Geometric Dimensioning and Tolerancing (GD&T) is a crucial tool used in CAD to ensure that sheet metal fabrication drawings meet key quality metrics. GD&T helps in defining the geometry of parts and assemblies, which .

Digital Fabrication Tools 3D Printers. Additive manufacturing (AM) or 3D printing processes create parts by successively adding material layer by layer until a physical part is created.. Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filament, which a print nozzle then deposits layer by layer in the build area.FDM is the most affordable 3D printing .In this webinar, Shane Wighton, engineering lead at Formlabs, will teach you how to form sheet metal with SLA 3D printed tools. Learn specific design considerations and application examples for printed tools suitable for your machine shop or assembly line.

Digital Fabrication Tools 3D Printers. 3D printing or additive manufacturing (AM) technologies create parts by successively adding material layer by layer until a physical part is created. Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filament, which a print nozzle then deposits layer by layer in the build area.FDM is the most affordable 3D printing .

If the application requires a metal jig of fixture, for a high heat or high force application, machining is the appropriate fabrication method. However, as 3D printing technologies advance in terms of accuracy and material availability, .Those familiar with rapid prototyping may find themselves asking about the differences between rapid prototyping and rapid tooling.. Rapid prototyping is the group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. Because these parts or assemblies are usually constructed using additive .

sheet metal forming tools

Fabrication; Cost $$ Production or Lead time: A few hours to days: Accuracy ★★★☆☆ Materials: 80/20 aluminum extrusion, sheet metal, plastics, wood, mechanical fasteners: Tools required: Variety of power tools for cutting, forming, welding, and assembly: ProsFormlabs.com Store. White Paper How to do Rapid Tooling for Sheet Metal Forming with 3D Printed Dies. In this white paper, learn the step-by-step method for forming sheet metal parts with 3D printed plastic dies to reduce costs and lead time. . Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts at .Digital Fabrication Tools 3D Printers. Additive manufacturing (AM) or 3D printing processes create parts by successively adding material layer by layer until a physical part is created.. Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filament, which a print nozzle then deposits layer by layer in the build area.FDM is the most affordable 3D printing .

Those familiar with rapid prototyping may find themselves asking about the differences between rapid prototyping and rapid tooling.. Rapid prototyping is the group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. Because these parts or assemblies are usually constructed using additive .In this white paper, learn how engineers can leverage the speed and flexibility of 3D printing without the expense of direct metal printers by using metal casting workflows, including detailed walkthroughs of sand casting and investment casting processes with .Typically in FRP fabrication, the continuous straight fibers are joined in the matrix to form individual plies, which are laminated layer-by-layer onto the final part. . thermoforming or sheet metal forming to deliver low-volume batches. . Additionally, the Formlabs Resin Library has engineering materials with mechanical and thermal .Formulas: Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern. Material Thickness (MT) – The gauge of the material in decimal form. Bend Angle (B<) – The inside angle between the two legs or flanges of a bend.

Typically in FRP fabrication, the continuous straight fibers are joined in the matrix to form individual plies, which are laminated layer-by-layer onto the final part. . thermoforming or sheet metal forming to deliver low-volume batches. . Additionally, the Formlabs Resin Library has engineering materials with mechanical and thermal .Digital Fabrication 101. Guide. Introduction to Vacuum Forming. Guide. . How to do Rapid Tooling for Sheet Metal Forming with 3D Printed Dies. inar. Sheet Metal Forming: Quickly Produce Tools In-House with 3D Printing . Everything You Have Come to Expect from Formlabs, Now 4x Faster. inar. Discover the Complete Form 4 Workflow in 20 .Property Value Mechanical Properties Ultimate tensile strength 18.6 (green) or 31.8 (post-cured) MPa Young’s modulus (modulus of elasticity) 0.45 (green) or 1.26 (post-cured) GPa Elongation at break 67 (green) or 49 (post-cured) % Physical Properties UV resistance No Thermal Properties Thermal expansion coefficient 117 (green) or 145.1 (post-cured) × 10-6/ºC Electrical Properties .

Property Value Mechanical Properties Ultimate tensile strength 38 (green) or 65 (post-cured) MPa Young’s modulus (modulus of elasticity) 1.6 (green) or 2.8 (post-cured) GPa Elongation at break 12 (green) or 6.2 (post-cured) % Post Treatments Post-Processing Post-curing Common Applications High-detail prototypes Customised parts and models Light pipes Millifluidic devices

blood of the dead electric junction boxes

I was watching a program about disaster preparedness, and it was suggested that the metal enclosure of a common shipping container (of the intermodal variety) would be sufficient to protect its contents from a large electromagnetic pulse (the kind that could affect an .

sheet metal fabrication formlabs|sheet metal forming