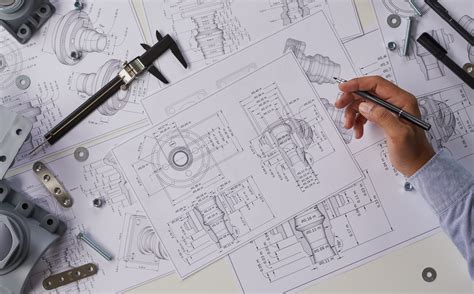

can a cnc machine use a hand drawing Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and . Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere!

0 · technical drawings for cnc

1 · engineering drawing for cnc manufacturing

2 · cnc machining drawings

3 · cnc drawing process

4 · basic drawings for cnc

Aluminum fencing requires significantly less maintenance than wrought iron. .

Below are some things to consider when trying to figure out can a cnc machine use a hand drawing. How much faster is CNC? CNC machines are faster and produce less waste than their manual counterparts.

This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and .

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and .This Instructable documents my process of converting a 3-axis CNC milling tool (a machine designed for cutting 2D and 3D forms out of wood, foam, and metal) into an interactive tool for painting.

In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your . You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, . The technical drawings for CNC machining are often created using Computer Aided Design (CAD) software or by hand with drafting tools. The accuracy of these drawings is critical as they serve as a blueprint for the CNC .Modern CNC machining systems can interpret the geometry of a part directly from CAD, which means that additional documentation, such as technical drawings, isn’t always required. However, while technical drawings are not necessary to .

Below are some things to consider when trying to figure out can a cnc machine use a hand drawing. How much faster is CNC? CNC machines are faster and produce less waste than their manual counterparts.

Technical drawings for CNC machining can be hand-drawn or scanned into digital files, and they may either be scaled down to a smaller size for use on CNC machines or enlarged for easier viewing. Regardless of their format, technical drawings must always include accurate information regarding dimensions, tolerances, material types, and . This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part.

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.

This Instructable documents my process of converting a 3-axis CNC milling tool (a machine designed for cutting 2D and 3D forms out of wood, foam, and metal) into an interactive tool for painting.In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your pencils and let's get started! You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, preparing the CAD files for CNC machining is advisable. The technical drawings for CNC machining are often created using Computer Aided Design (CAD) software or by hand with drafting tools. The accuracy of these drawings is critical as they serve as a blueprint for the CNC machine to follow when producing the part.

Modern CNC machining systems can interpret the geometry of a part directly from CAD, which means that additional documentation, such as technical drawings, isn’t always required. However, while technical drawings are not necessary to request a quote for CNC machining, they are still very important and widely used in manufacturing. Below are some things to consider when trying to figure out can a cnc machine use a hand drawing. How much faster is CNC? CNC machines are faster and produce less waste than their manual counterparts. Technical drawings for CNC machining can be hand-drawn or scanned into digital files, and they may either be scaled down to a smaller size for use on CNC machines or enlarged for easier viewing. Regardless of their format, technical drawings must always include accurate information regarding dimensions, tolerances, material types, and .

electrical box for light fixture basement

This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part. CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.This Instructable documents my process of converting a 3-axis CNC milling tool (a machine designed for cutting 2D and 3D forms out of wood, foam, and metal) into an interactive tool for painting.

In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your pencils and let's get started! You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, preparing the CAD files for CNC machining is advisable. The technical drawings for CNC machining are often created using Computer Aided Design (CAD) software or by hand with drafting tools. The accuracy of these drawings is critical as they serve as a blueprint for the CNC machine to follow when producing the part.

technical drawings for cnc

If you can’t make the connections in an existing electrical box, you need a junction box. The box needs to be facing out from the wall to make sure the wires are easy to reach. The edge of the opening should be flush with the wall.

can a cnc machine use a hand drawing|cnc machining drawings