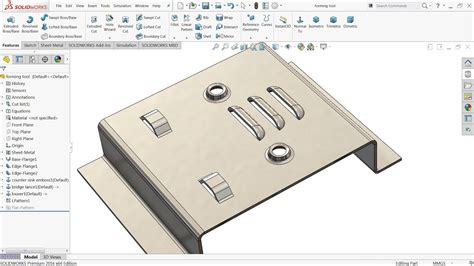

amke an extruded part into a sheet metal in solidworks Relief Type: Select the type of relief cut to be added: Rectangular; Obround; Tear; . Inspiration for a coastal kitchen remodel in Geelong with an integrated sink, open cabinets, light wood cabinets, stainless steel countertops, metallic backsplash and an island.

0 · solid work to sheet metal converter

1 · solid work to sheet metal

2 · solid to sheet metal worksheets

3 · convert solid part to sheet metal

4 · convert sheet metal to solid worksheet

5 · convert SolidWorks to sheet metal

6 · SolidWorks sheet metal conversion tool

7 · SolidWorks edge to sheet metal

Tom Silva shows the apprentices how to properly install wood shingles.#ThisOldHouse #AskTOHSUBSCRIBE to This Old House: http://bit.ly/SubscribeThisOldHouseTh.

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part.Relief Type: Select the type of relief cut to be added: Rectangular; Obround; Tear; .You can create a sheet metal part by converting a solid or surface body using .You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .

This tutorial walks you through how to convert a solid body into sheet metal, enabling you to flatten it into a flat pattern for manufacturing, without having to recreate the . This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. Design high quality, manufacturable sheet metal parts in SOLIDWORKS by learning how to create Solid Bodies and how to use the Create to Sheet Metal, Rips and Insert Bend tools. By converting a solid part to sheet metal within SOLIDWORKS, you can simulate these fabrication processes, ensuring the part can be manufactured accurately and efficiently.

In this blog you’ll learn how to use the Convert to Sheet Metal tool to build sheet metal assemblies with multiple sheets the easy way.Assuming a .5 k factor, draw a construction arc with a small gap -> dimension the length of the arc to your given flat length -> offset from the arc by half the material thickness -> extrude a sheet .The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal .The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part.

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. This tutorial walks you through how to convert a solid body into sheet metal, enabling you to flatten it into a flat pattern for manufacturing, without having to recreate the entire part.

Converting a regular solid or surface body to a sheet metal model that can be flattened (unfolded), can help facilitate the manufacturing of the part. Flattened parts can be saved in either DXF or DWG formats, which can be directly read into laser/plasma cutting software.This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. Design high quality, manufacturable sheet metal parts in SOLIDWORKS by learning how to create Solid Bodies and how to use the Create to Sheet Metal, Rips and Insert Bend tools. By converting a solid part to sheet metal within SOLIDWORKS, you can simulate these fabrication processes, ensuring the part can be manufactured accurately and efficiently.

In this blog you’ll learn how to use the Convert to Sheet Metal tool to build sheet metal assemblies with multiple sheets the easy way. Assuming a .5 k factor, draw a construction arc with a small gap -> dimension the length of the arc to your given flat length -> offset from the arc by half the material thickness -> extrude a sheet metal base flange.The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part.You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. This tutorial walks you through how to convert a solid body into sheet metal, enabling you to flatten it into a flat pattern for manufacturing, without having to recreate the entire part.

Converting a regular solid or surface body to a sheet metal model that can be flattened (unfolded), can help facilitate the manufacturing of the part. Flattened parts can be saved in either DXF or DWG formats, which can be directly read into laser/plasma cutting software.This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. Design high quality, manufacturable sheet metal parts in SOLIDWORKS by learning how to create Solid Bodies and how to use the Create to Sheet Metal, Rips and Insert Bend tools. By converting a solid part to sheet metal within SOLIDWORKS, you can simulate these fabrication processes, ensuring the part can be manufactured accurately and efficiently.

cnc machine time on hardened steel

In this blog you’ll learn how to use the Convert to Sheet Metal tool to build sheet metal assemblies with multiple sheets the easy way. Assuming a .5 k factor, draw a construction arc with a small gap -> dimension the length of the arc to your given flat length -> offset from the arc by half the material thickness -> extrude a sheet metal base flange.

solid work to sheet metal converter

solid work to sheet metal

solid to sheet metal worksheets

Why I prefer Metal Raised Garden Beds. Metal beds last longer overall. Galvanized or Aludized metal last 20 years plus. This against typical wood beds only reaching 5-10 years on average. Metal beds may seem expensive, but over time are actually cheaper owing to the short term nature of wood and the possible cost of treatment over the years.

amke an extruded part into a sheet metal in solidworks|solid to sheet metal worksheets