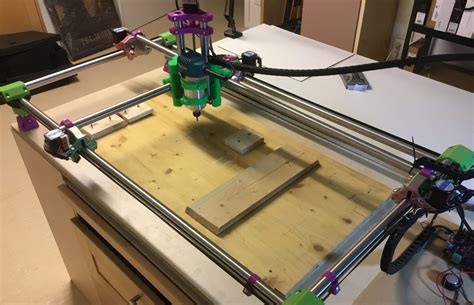

building a cnc from an old machine CNC Basics (Building a Cnc Machine Part 1): So you want to know more about how to make a CNC machine? Whether it is a 3D printer or a mil of some sort, this will take you through the basics a give you a nice idea of how they work, . Shop for exclusive NASCAR race used memorabilia from the Hendrick Motorsports Team including sheet metal, track shirts, banners, and other gear.

0 · make your own cnc machine

1 · homemade cnc router machine

2 · homemade cnc machine plans

3 · do it yourself cnc machine

4 · building your own cnc router

5 · build your own cnc mill

6 · build your own cnc machine

7 · build it yourself cnc router

The Wm. J. Donovan Co. is able to meet the needs of any client and any size project utilizing our state-of-the-art 45,000 square foot facility in Philadelphia, along with a 15,000 square foot warehouse just across the street from our main facility and a 7,000 square foot warehouse and office space in North Wales, PA.

make your own cnc machine

What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers. In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the vid. My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.CNC Basics (Building a Cnc Machine Part 1): So you want to know more about how to make a CNC machine? Whether it is a 3D printer or a mil of some sort, this will take you through the basics a give you a nice idea of how they work, .

led mounted to junction box

If you are looking to build a CNC machine, you can opt to create a custom one from scratch or purchase a CNC kit. The former approach takes much longer than the latter and requires you to possess advanced skills. Despite appearances, [This Old Tony]’s latest series has little to do with CNC-ifying an Etch A Sketch. Although he certainly achieves that, more or less, automating the classic toy is just the.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers.

In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the vid. My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to.Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have made in the first two weeks of using the . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

CNC Basics (Building a Cnc Machine Part 1): So you want to know more about how to make a CNC machine? Whether it is a 3D printer or a mil of some sort, this will take you through the basics a give you a nice idea of how they work, operate and what parts you will need or can choose from. .

If you are looking to build a CNC machine, you can opt to create a custom one from scratch or purchase a CNC kit. The former approach takes much longer than the latter and requires you to possess advanced skills. Despite appearances, [This Old Tony]’s latest series has little to do with CNC-ifying an Etch A Sketch. Although he certainly achieves that, more or less, automating the classic toy is just the.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.

What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers. In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the vid. My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to.

Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have made in the first two weeks of using the . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

homemade cnc router machine

homemade cnc machine plans

CNC Basics (Building a Cnc Machine Part 1): So you want to know more about how to make a CNC machine? Whether it is a 3D printer or a mil of some sort, this will take you through the basics a give you a nice idea of how they work, operate and what parts you will need or can choose from. .

If you are looking to build a CNC machine, you can opt to create a custom one from scratch or purchase a CNC kit. The former approach takes much longer than the latter and requires you to possess advanced skills. Despite appearances, [This Old Tony]’s latest series has little to do with CNC-ifying an Etch A Sketch. Although he certainly achieves that, more or less, automating the classic toy is just the.

lded light built in junction box

BBB accredited since 4/12/2019. Roofing Contractors in Willoughby, OH. See BBB rating, reviews, complaints, request a quote & moreServing north Alabama, Willoughby Roofing & Sheet Metal Inc specializes in residential and commercial roof installation and repair services. 24/ emergency leak repair. Multiple warranties available. Competitive prices. Call today.

building a cnc from an old machine|build it yourself cnc router