cnc machining medical parts The future of CNC machining in the medical sector looks extremely promising. Advancements in automation, materials, integration with additive manufacturing, digital technologies, customization and quality assurance will continue to drive . The Tuf-tite 4 Hole D-Box with Lid is designed to accommodate multiple pipes, allowing for an even distribution of wastewater into the leach field.

0 · parts made by cnc machine

1 · online cnc shop

2 · cnc replacement parts manufacturer

3 · cnc machining parts usa

4 · cnc machining parts supplier

5 · cnc machining parts manufacturer

6 · cnc machining custom made parts

7 · cnc machine parts list

Buy Tuf-Tite 6 Hole Drain Distribution Box with Lid and Seals from Walmart Canada. Shop for more available online at Walmart.ca.

High precision CNC machined parts and components for medical devices and surgical instruments. Get your instant quote today!We fabricate a wide variety of medical equipment components with CNC machining, including graspers, ligation devices, handheld surgical equipment and catheters.As an ISO 9001:2015 certified and ISO 13485:2008 compliant company, we are a medical parts specialist. The manufacturing of medical parts requires working with tighter tolerances and unique materials. The top-of-the-line equipment, .The future of CNC machining in the medical sector looks extremely promising. Advancements in automation, materials, integration with additive manufacturing, digital technologies, customization and quality assurance will continue to drive .

Metal materials for CNC machined medical devices must be corrosion-resistant, sterilizable, and easy to clean. Among them, stainless steel is a common metal material for manufacturing medical parts because of its .

Our medical parts precision machining service offers our clients confidence in the products they receive. Confidence is a uniquely meaningful term if you are a designer or manufacturer of medical devices. We 3Q MACHINING is specialized in all different medical parts machining manufacturing. Thanks to our trusted reputation for meeting exceptional requirements. Medical parts such as joint implants, cardiovascular implants, and ventricular assist devices have complex geometries. Creating such geometries is often not possible without using 5-axis CNC machining operations while also maintaining required geometric tolerances and surface finish requirements. CNC machining is fast becoming the leading method for manufacturing medical parts. The medical industry requires precise and high-quality components. CNC machining makes it possible to create these parts with a high degree of accuracy, consistency, and speed.

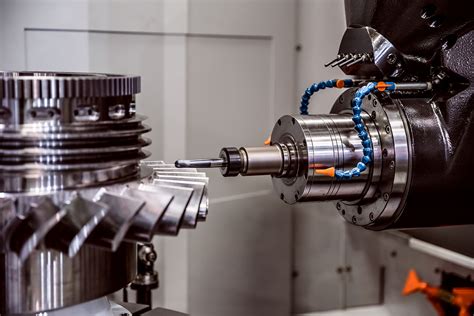

Medical CNC machining is a specialized process that utilizes computer numerical control (CNC) technology to manufacture precision medical components and devices. This advanced manufacturing technique allows for the precise cutting, CNC milling, and shaping of materials into parts with tight tolerances and complex geometries.

Medical CNC Machining. Here are some factors determining the ideal material for machining medical parts: Chemical Resistance. Most medical equipment, such as ventilator masks & tubes, diagnostic and testing equipment, surgical equipment, etc., often need repeated use, cleaning, and sterilizing.AbleMed customizes precision medical device components.Our services include medical CNC machining,medical injection molding,CNC medical,medical device prototyping,rapid prototyping parts,and medical assembly.CNC Milling Machining PEEK Medical Parts; 2022-01-26. 4-Axis CNC Machining Aluminum 2011 Medical Parts; Request a Quote. For more than three decades, we simply the working process, from the prototypes to parts deliveried fast only with 4 simple steps. 1. Send Design For Quote.The Importance of CNC Machining in Medical Parts Manufacturing The medical industry is constantly innovating to find ways to improve the quality of life and treatment outcomes for patients. One such technology is computer numerical control ( CNC ) machining, which has become a revolutionary tool in the field of medical hardware manufacturing.

CNC machining is important to handle the increasing demand for high-quality precision machined parts and prototyping in the medical industry. These CNC machined medical equipment and instruments must be on-demand manufacturing and meet the industry’s standards. Therefore, product teams and manufacturers rely on CNC machining to meet quality standards .Our medical parts precision machining service offers our clients confidence in the products they receive. Confidence is a uniquely meaningful term if you are a designer or manufacturer of medical devices. . Cnc Machining Aircraft Parts Learn more detail for Machining Field Reply Within 24 Hours Hotline:+86-769-88033280 E-mail: sales .If you need CNC Swiss Machining or CNC Turning and Milling for your healthcare project, check out our medical CNC Machining services today! 920.954.9648 Menu . About. About McCormick; Blog; Careers; Quality; Machining Services. Swiss Precision; CNC Milling . Machining medical parts entails the use of a broad range of materials that are . Medical CNC machining utilizes different processes & techniques, milling is one of them. Understand how CNC milling upholds precision & medical safety. . Here, CNC milling ensures that medical parts, from implants to .

Case Studies PTJ Hardware Inc, High Precision CNC Machining, Rapid Milling ,Turning and Special CNC Parts&more. E-mail: [email protected]. Hotline:+86 0769 82886112 Blog FAQ Video. Sitemap. Toggle navigation. Home; . CNC .

parts made by cnc machine

online cnc shop

CNC machining, the process by which machinists use code to automatically run a machine like a mill, router, or lathe, can help these manufacturers produce parts faster and more efficiently. In turn, hospitals, .

Prerequisites for CNC Machining Medical Parts. It is not the same as machining components for other industries when it comes to machining medical parts for the medical business. In contrast to most common metal components, which must conform to ISO 9001 for quality management, medical parts must adhere to additional standards.

CNC machining are the ideal method for processing such Medical parts, multi-axis linkage CNC turning and milling have outstanding performance in the field of precision medical equipment manufacturing, which is mainly used to manufacture orthopedic implants (vertebral hooks, bone plates, bone screws, acetabular balls, etc.) and dental implants .

CNC Machining for Medical Device Applications. From connected devices to mass personalization of healthcare products, digital manufacturing can accelerate development in many different ways. We offer production-grade materials for functional and regulatory testing of medical parts. Some common components we machine for medical applications include:

Contract medical equipment parts manufacturers & medical machining specialists utilizing multiple medical-grade materials for precision medical devices. Skip to content (603) 644-1555; [email protected]; . Our precision medical CNC machine shop features .The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are [.]SR Machining’s extensive experience is in the manufacture and production of the precision CNC machining of plastics, alloys and metals. One of the strengths of . manifolds that house fiber optics (for use in surgical procedures), and various other cartridges and parts with medical uses and applications. Medical components can be produced in . Introduction to CNC Machining in the Medical Industry. At Worthy Hardware, we’ve harnessed the power of our 35 CNC machines, including advanced 3-axis and 5-axis machining centers, to produce components that meet the stringent standards of the medical field.. Our clientele, spanning Europe, North America, Australia, and New Zealand, often seek .

CNC machining is important to handle the increasing demand for high-quality precision machined parts and prototyping in the medical industry. These CNC machined medical equipment and instruments must be on-demand manufacturing and meet the industry’s standards. Therefore, product teams and manufacturers rely on CNC machining to meet quality standards .With CNC machining, parts can be made to exact specifications and tolerances, which gives designers more freedom to create complex shapes and designs. Improved durability of parts . Medical CNC machining is not just about designing or manufacturing medical appliances or instruments. It’s about offering high-grade service that ensures the .

cnc replacement parts manufacturer

cnc machining parts usa

The Tuf-Tite B1 Riser is a square riser that can be attached to the top of your Tuf-Tite 4 Hole Distribution Box. This allows you to bring the lid up to grade allowing for easy access. The risers are stack able so you will can purchase as many as you need to reach desired height.

cnc machining medical parts|cnc replacement parts manufacturer