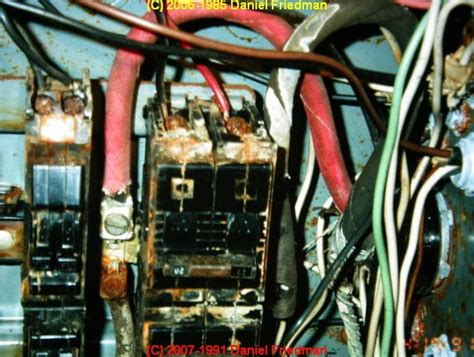

corroded electrical box Here we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report. Yantrang Precise has earned its reputation as an industry-leading CNC machine manufacturer by dedicating itself to research and development, ensuring that its products are at the cutting .

0 · electrical panel cabinet corrosion

1 · damaged electrical panels

2 · corrosion on electrical panels

3 · corroded panel cabinet

Rule 174. Box junctions. These have criss-cross yellow lines painted on the road (see ‘Road markings’). You MUST NOT enter the box until your exit road or lane is clear. However, you may.

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, . When should a corroded or damaged electric panel cabinet or disconnect box be replaced? They are officially called “electrical enclosures,” and serve two primary purposes: to .

Is this corrosion, indicative of a moisture issue? Is this a safety hazard, or just something to prevent from getting worse? In case it is relevant - outside the house on the other side of the service panel, the electric meter box . If water gets inside a breaker box, it can cause: Electrocution; Corrosion to the metal breaker box; Breaker switch corrosion; Electrical fire; Internal circuit breaker malfunction; Below we’ll take a closer look at five .Here we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report. Rust in an electrical panel is bad for multiple reasons. For one, if the outer housing of the panel box catches rust, it can compromise the housing itself. As rust spreads, it leads to corrosion, which eats through the metal .

electrical panel cabinet corrosion

Building diagnostics help determine the causes of corrosion in electrical boxes. A general service panel and two controlled-load panels for in-floor heating exhibit signs of moisture damage. Consequences of rusted or corroded electrical panels range from simply needing maintenance to needing a replacement panel.Don't ignore the signs of an outdated electrical panel box or breaker. Learn the warning signs and how to replace them to ensure your home's safety.

metal shed people turn into houses

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. When should a corroded or damaged electric panel cabinet or disconnect box be replaced? They are officially called “electrical enclosures,” and serve two primary purposes: to protect the user of the equipment from electrical shock, and shield the internal components from the environment. Is this corrosion, indicative of a moisture issue? Is this a safety hazard, or just something to prevent from getting worse? In case it is relevant - outside the house on the other side of the service panel, the electric meter box does show signs of rust and we need the utility company to come take a look at that.Field observations of residential service panel connections and components discovered significant occurrences of rust, corrosion, and damage to electrical equipment, risking failure to trip on overcurrent and thus risking building fires.

damaged electrical panels

If water gets inside a breaker box, it can cause: Electrocution; Corrosion to the metal breaker box; Breaker switch corrosion; Electrical fire; Internal circuit breaker malfunction; Below we’ll take a closer look at five possible outcomes that may occur if water gets inside a breaker box or onto a circuit panel. 1. Electrocution Risk is HighHere we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report. Rust in an electrical panel is bad for multiple reasons. For one, if the outer housing of the panel box catches rust, it can compromise the housing itself. As rust spreads, it leads to corrosion, which eats through the metal housing.

Building diagnostics help determine the causes of corrosion in electrical boxes. A general service panel and two controlled-load panels for in-floor heating exhibit signs of moisture damage. Consequences of rusted or corroded electrical panels range from simply needing maintenance to needing a replacement panel.

Don't ignore the signs of an outdated electrical panel box or breaker. Learn the warning signs and how to replace them to ensure your home's safety. Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit.

When should a corroded or damaged electric panel cabinet or disconnect box be replaced? They are officially called “electrical enclosures,” and serve two primary purposes: to protect the user of the equipment from electrical shock, and shield the internal components from the environment.

Is this corrosion, indicative of a moisture issue? Is this a safety hazard, or just something to prevent from getting worse? In case it is relevant - outside the house on the other side of the service panel, the electric meter box does show signs of rust and we need the utility company to come take a look at that.

Field observations of residential service panel connections and components discovered significant occurrences of rust, corrosion, and damage to electrical equipment, risking failure to trip on overcurrent and thus risking building fires.

If water gets inside a breaker box, it can cause: Electrocution; Corrosion to the metal breaker box; Breaker switch corrosion; Electrical fire; Internal circuit breaker malfunction; Below we’ll take a closer look at five possible outcomes that may occur if water gets inside a breaker box or onto a circuit panel. 1. Electrocution Risk is HighHere we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report. Rust in an electrical panel is bad for multiple reasons. For one, if the outer housing of the panel box catches rust, it can compromise the housing itself. As rust spreads, it leads to corrosion, which eats through the metal housing. Building diagnostics help determine the causes of corrosion in electrical boxes. A general service panel and two controlled-load panels for in-floor heating exhibit signs of moisture damage.

metal screw housing

Consequences of rusted or corroded electrical panels range from simply needing maintenance to needing a replacement panel.

corrosion on electrical panels

metal shed houses inside

metal saltine cracker box

Read real reviews and see ratings for Las Vegas, NV metal fabricators and restorers for free! This list will help you pick the right metal fabricators and restorers in Las Vegas, NV.

corroded electrical box|corrosion on electrical panels