steel box section tensile strength calculator for structural steel hollow sections designed to AS 4100:1998. TubeComp® can provide exact calculated values for specific effective lengths and screens are dynamically updated . Metal Supermarkets offers a variety of shapes and grades of bronze, cut to the size you need, including: 932 and 954. Select from one of the available shapes below to get started. Or contact your closest store for assistance with metal sourcing.

0 · structural steel hollow sections

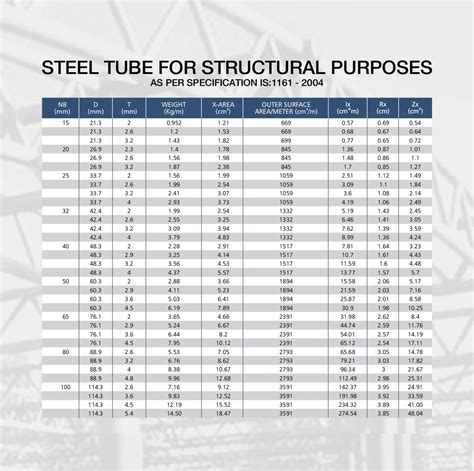

1 · structural steel hollow section table

2 · structural steel hollow section dimensions

3 · structural steel hollow capacity chart

4 · steel hollow section capacity table

5 · box steel strength chart

6 · box steel strength

7 · 2500mm steel box strength

When it comes to welding a car, one commonly used method is Metal Inert Gas (MIG) welding. MIG welding utilizes a wire that is fed directly through the welder, along with a shielding gas and filler material.

Table of design properties for steel square profiles / square hollow sections (SHS) according to Eurocode 3 including cross-section dimensions & design resistance.Nominal width minus 3 times the design wall thickness, t (in.) Torsional shear constant of cross-section (in.3) Outside diameter of round HSS (in.) Nominal depth minus 3 times the design .calculator for structural steel hollow sections designed to AS 4100:1998. TubeComp® can provide exact calculated values for specific effective lengths and screens are dynamically updated . I haven't worked out deflection but at 15% of capacity it's going to be minimal. 2mm wall I'd have to work out from first principles to tell you exactly what it will take, but 65kg won't .

%PDF-1.6 %âãÏÓ 1 0 obj /Rotate 0 /HDAG_Tools 2 0 R /TrimBox [28.3465 28.3465 447.874 623.622] /CREO_Tools 3 0 R /MediaBox [0.0 0.0 476.22 651.968] /CropBox [28.3465 28.3465 .illustrating the design of structural hollow sections for beams and columns in buildings. All the examples were prepared by Miss M E Brettle and checked by Mr A S Malik of The Steel .

The Structural Steel Properties and Design Charts Catalogue is a directory of products and services available from Fletcher Easysteel and is provided as a guide to assist customers .High strength low alloy steel plate (comparable to CSA G40.21-50A). Intended for applications requiring improved strength levels and increased resistance to atmospheric corrosion. .

For structural design according to Eurocode 3 (EN1993-1-1), the nominal values of the yield strength f y and the ultimate strength f u for structural steel are obtained as a simplification from EN1993-1-1 Table 3.1, which is . Research on the behavior of CFS box sections has reached a relatively advanced stage, with investigations of various steel grades. This observation is evident in the work of Gardner and Yun [5], who collated the results of the material property tests on various CFS grades.More recently, significant attention and efforts have been spent studying the behavior .Once you have a section and real-world structures it’s more complicated. Bending due to long spans is hard to resist, so requiring large material (Ritter for stress or deflection, but the basic principle holds). . steel does have higher .

Young's Modulus (or Tensile Modulus alt. Modulus of Elasticity) and Ultimate Tensile Strength and Yield Strength for materials like steel, glass, wood and many more. Engineering ToolBox - Resources, Tools and Basic . Durable and strong - the mild steel box section shape gives these steel products incredible strength. What’s more, the malleability of mild steel (thanks to its higher carbon content) means these are easier to form, and also incredibly durable. This means that these sections can withstand large amounts of pressure. Before you Buy Steel Box . Induced residual tensile and compressive stresses generated by the fabrication process can cause premature buckling and reduce the ultimate axial strength of welded steel box sections subjected to .

With high torsion rigidity and compressive strength, JINDAL-HISSAR make MS Hollow Section Pipes are comparably more efficient, convenient, durable and long life span than conventional steel sections. The excellent distribution of material around the axis of the square and rectangular steel hollow sections allows for remarkable strength . Tensile residual stresses are not significantly effected by the plate slenderness and the thickness of plates, . Residual stress of 460 MPa high strength steel welded box section: experimental investigation and modeling. Thin-Walled Struct, 64 (2013), pp. 73-82. View PDF View article View in Scopus Google Scholar

(CNC) machine. The yield strength (Fy), the ultimate tensile strength (Fu), the elongation, and the dimensions for the steel sections were depicted in (Table 1). The tensile test results was conform to the requirements of ASTM A36/A36M specifications [18]. Table 1. Tensile test results of the steel material Steel material Dimensions,

Through data fitting and reliability analysis, buckling curves tailored to S35657 austenitic stainless steel welded box-section and I-section long columns for global buckling were proposed for the first time, providing guidance for relevant designs based on the European code (prEN 1993-1-4), the American code (SEI/ASCE 8-22) and the Chinese .Residual stresses in high strength steel welded box sections . Correlating weld process conditions, residual strain and stress, microstructure and mechanical properties for high strength steel—the role of neutron diffraction strain scanning. David Hughes. Materials Science and Engineering: A, 2006. Six welded square box section shapes were measured in this program as summarized in Table 1 where the geometrical parameters are defined in Fig. 1.All component steel plates of Q460C (460 MPa) HSS were flame cut with moderate thicknesses of 10 mm, 12 mm and 14 mm, and welded together using butt welds.During the welding process, the manual .

structural steel hollow sections

It was indicated that the box-sections had a lower compressive residual stress ratio compared to 235MPa steel, and the hole-drilling method was better to adopt the tensile residual stresses.

The experimental programme was performed on three π-shaped sections and two cruciform sections, fabricated from 5 mm thick S700MC high strength steel plates by means of gas metal arc welding, and included material tensile coupon tests and membrane residual stress measurements, with two measurements for each of the five S690 high strength steel .Residual stresses in high strength steel welded box sections . Correlating weld process conditions, residual strain and stress, microstructure and mechanical properties for high strength steel—the role of neutron diffraction strain scanning. David Hughes. Materials Science and Engineering: A, 2006. download Download free PDF View PDF .SECTIONS PAINTED & GALVANISED SHS AUSTRALIAN STANDARDS Hollow sections to be used for structural purposes are manufactured to meet: AS/NZS 1163 - Structural Steel Hollow Sections (Grades C250, C350, C250L0 & C350L0). Standard Mechanical Properties - Structural Tube & Pipe *L0 designation indicates guaranteed impact strength

Box section strength, how to calculate. Thread starter barracuda816; Start date Apr 17, 2017; 1; 2; 3; Next. 1 of 3 . Of course i could weld a 1mt section of box onto a suitable hold and try it but i would like to know the maths behind it. . I is the "Area moment of inertia" a property related to the shape of the steel F = 100*9.81 = 981N L .

the residual stress distribution of three box section specimens made of three different steel grades (Domex 420, Weldox 700, Weldox 1100). Pavlovcˇicˇ et al. (2012) measured the residual stress distribution of a welded box section made of S355 steel grade. Two welded box sections made of S690 HSS were tested by Nishino et al. (1967).The design resistances of the profiles correspond to cross-section resistances reduced by the partial material factor γ M0 in accordance with EN1993-1-1 §6.2.3(2), §6.2.4(2), §6.2.5(2), §6.2.6(2). The aforementioned design resistances do not take into account a) flexural buckling, b) local shell buckling, c) interaction effects of axial force, shear force, bending moment, and d . Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of CNC machining material or product design. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and . The maximum tensile residual stresses were found to reach approximately 90% and 85% of the 0.2% proof strength for S35657 stainless steel box sections and I-sections, respectively. Comparisons of the test results with existing residual stress distribution models revealed a significant deviation.

The test specimens were fabricated from Q460 steel (nominal yield strength 460 MPa) plates s in China.The original plate with thickness of 11 mm was flame cut into small component plates.Four component plates were welded together to form a box section specimen by manual gas metal arc welding, as shown in Fig. 2.As current practice does not employ . High-strength steel (HSS) has a higher yield-tensile strength ratio and a lower fracture elongation than conventional mild steel, resulting in poor ductility in comparison to the latter. This paper aims to investigate the hysteretic performance of Grade Q690 steel welded box-section columns with slender webs.

In 1967, Nishino et al. [7] studied local buckling of high-strength steel (717 MPa, 800 MPa) columns on welded box-sections, and discussed the magnitude and distribution of residual stress. Their plate slenderness ratios were 26.2 and 44, and the thickness was 6.5 mm.In 1982 and 1984, Usami and Fukumoto [8], [9] presented the average residual stress of two sets of .

The residual stresses distributed in all cross-section satisfies the self-balancing requirement. Comparison of distribution and magnitude of residual stresses between test data and existing models are made. A simplified model is suggested to estimate the residual stresses distribution of steel welded box section made of 800 MPa high strength steel. In the tables, E is elastic modulus, f y is yield strength, ε y is yield strain, ε st is yield stage end strain, f u is tensile strength, . Residual stress of 460 MPa high strength steel welded box section: experimental investigation and modeling. Thin-Walled Struct., 64 (4) (2013), pp. 73-82. View in Scopus Google Scholar

structural steel hollow section table

IS 4923 : 1997 HOLLOW STEEL SECTIONS FOR STRUCTURAL USE — SPECIFICATION . Tensile testing (second revision) a) b) Cl 3 TERMINOLOGY A hot formed rectangular hollow sectional with outside dimensions of 40 mm depth, 25 mm breadth and 2.65 mm thickness is designated as 40 x 25 x 2.65 HF RHS. .

Junction box 47B is the closest junction box to the last one you flipped, as it’s located on the same level as you. If you choose to flip it first, . See more

steel box section tensile strength|2500mm steel box strength