metal 3d printing vs cnc machining The development of stronger 3D printing materials has encouraged manufacturers across industries to explore CNC vs 3D printing, and find ways to 3D print functional parts that were previously CNC machined. The 3D printing . $23.49

0 · subtractive manufacturing 3d printing

1 · metal 3d printing vs cnc

2 · is 3d printing better than cnc

3 · cnc machine vs 3d printer

4 · 3d printing vs cnc manufacturing

5 · 3d printing and cnc machining

Check out our floating wood box selection for the very best in unique or custom, handmade pieces from our boxes & bins shops.

Compare metal 3D printing and CNC machining to find the best method to make metal parts. 3DSRPO metal 3D printing services and post-processing solutions.CNC Machining of Metal Parts vs 3D Printing. CNC milling technology has existed ever since MIT introduced it in the 1950s. CNC routing is essentially the reverse of 3D printing. Instead of using a computer to control the armature and print .

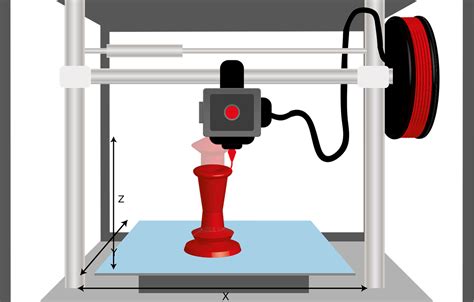

CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications. This article discusses a detailed review and a distinction between CNC machining vs 3D printing. It also includes the advantages of either process and factors to .The development of stronger 3D printing materials has encouraged manufacturers across industries to explore CNC vs 3D printing, and find ways to 3D print functional parts that were previously CNC machined. The 3D printing .3D Printing. 3D printing or additive manufacturing builds parts by adding layers of material until the object is created. M3DP (Metal 3D Printing) is an emerging technology with its own specific advantages and drawbacks. M3DP offers reduced material waste, efficiency, and greater design freedom. Advantages. Very low up-front costsIs 3D printing or CNC machining better? 3D printing is cheaper for single parts but CNC can achieve tighter tolerances (±0.001″). NEW online CNC machining instant quote calculator. . Metal is more popular than plastic for CNC machining, though plastic has become increasingly popular. In contrast, plastics were once more popular than metals .

The advantages of CNC machining compared to 3D printing are: CNC machining uses engineering materials and delivers the full properties of the materials, undisrupted by the process. 3D printing, on the other hand, can sometimes achieve .

Ian J. Davies 2

Both CNC machining and 3D printing have significantly transformed the manufacturing landscape through the use of computer-guided processes. However, the fundamental difference lies in their approach to material transformation-CNC machining removes, while 3D printing adds. Within this guide, we will conduct a comprehensive comparison between CNC machining and 3D printing, . Learn what the differences are between CNC machining and 3D printing in order to find out if CNC machining or 3D printing is a better choice for your design..A Complement to CNC Machining. The vision of metal 3D printing companies has been to reduce the cost-per-part far enough so that additive manufactured parts can move towards larger volumes and in the direction of the industry holy grail, which is high volumes of end-use production parts. While new technologies are steadily moving in the .

What is 3D Printing? 3D printing, also known as additive manufacturing, is a process where parts are built layer by layer from materials like plastic, metal powder, or resin. Because it builds up from nothing, 3D printing enables the creation of complex shapes and internal structures not feasible with traditional machining. Best For:CNC Machining vs. 3D Printing: Top 10 Main Differences. . You can easily CNC machine plastic, metal, titanium alloys, wood, and composites. 3D printing machine, on the other hand, can work with very few materials. They can only be used on resins, plastics, some metals and .

Metal 3D Printing: Think of investing in a metal 3D printing system as establishing an on-demand manufacturing facility within your own company, giving you greater control over your production processes and timelines. While the initial investment in metal 3D printing equipment can be significant, it eliminates the need for expensive specialized .

The ability to produce complex metal parts easily and affordably without any tooling makes metal 3D printing very attractive. Join this webinar to learn specifically about how metal 3D printing compares to traditional CNC machining; comparing material properties, part economics, and throughput will all be discussed.Choosing the right manufacturing path: 3D printing vs. CNC machining metal parts CNC machining and 3D printing methods come with theirs own set of advantages and considerations, making the choice a complex but critical one for OEMs striving to meet the demands of precision, speed, and cost-effectiveness. Let’s explore the differences between CNC machining and 3D .

Let’s dive into the specifics of manufacturing these parts using CNC machining and metal 3D printing such as DMLS. CNC machining is typically more expensive. Machine costs range from ,000 to 0,000, setup costs .3D printing is easier. The only forces a printer has to overcome are the inertia of its (light weight) components. Mechanical accuracy, sufficient for 3D printing, is easily achieved. CNC mills have mich higher mechanical loads due to cutting forces, and the weight of the machine's elements.

Metal 3D printing is plagued by issues like porosity, . Aerospace is a perfect example of an industry in which 3D printing and CNC machining can nicely complement each other – CNC machining .As others have said, the two are similar but the process of getting there can be considered the inverse of one another. The simplest way to show the difference is via examples: 3D printed Globe VS CNC 4 axis globe.Both techniques produce a similar result but .

subtractive manufacturing 3d printing

The ability to produce complex metal parts easily and affordably without any tooling makes metal 3D printing very attractive. Join this webinar to learn spec.Plasma Cutters. According to CNC.com, a plasma cutter works on metals such as steel, aluminum, copper, or brass.It can cut through these materials using hot plasma jets. Like all CNC machines, you work with a computer to cut out specific parts of a material. It uses extreme heat to make the desired cut-outs on a piece of metal.. These cutters are found in welding shops, auto . The disadvantage of CNC Machining compared to Metal 3D Printing is: CNC machining uses special cutting tools to shape parts which means the need for such tools. Another process is required to manufacture the tool without such .Desktop metal 316L stainless steel material rods were used for metal 3D printing, and 316L stainless steel bulk material in billet form was used for CNC machining. Three impellers (AM1, AM2, AM3) were additive manufactured while three .

CNC Machining vs. 3D Printing Ideal Material. The ideal material is one of the first considerations when choosing between CNC machining and 3D printing. 3D printing can now handle various materials, including thermoplastics, ceramics, and metals, but this process has some limitations in terms of the product’s mechanical properties. This means that as a manufacturing process, it is not as useful or as viable as CNC machining for quality or quantity. These are the answers to the debate on CNC vs 3d printing. CNC vs 3d printing – the advantages of CNC Machining. CNC machining is a fairly simple concept that offers many advantages to manufacturers in almost every field of . However, CNC machining does have higher initial costs due to setup, tooling, and programming, which can make it less cost-effective for simple, low-volume prototypes compared to 3D printing. When to Choose 3D Printing Over CNC Machining. 3D printing is best suited for projects that prioritize speed, cost-efficiency, and design complexity. With large batches (e.g. over 500) the price for CNC machining of ABS will be lower than any 3D printing, especially with the parts where there is more material to remove than to print it. Conclusion : Go with 3D printing for small series and go with CNC machining for mid-large series as the cost reduces with quantity and gets much lower.

jordan sheet metal

joining techniques for sheet metal

Yamaha Banshee YFZ350 Extended Swingarms. What length of chain will I need for my swingarm?. You can use the chart or do a little math to get close to what you need, but keep in mind your chain may be stretched and the new one will not be.

metal 3d printing vs cnc machining|3d printing and cnc machining