cnc machine additive manufacturing Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and . With its clean white design, this junction box seamlessly blends into any environment .

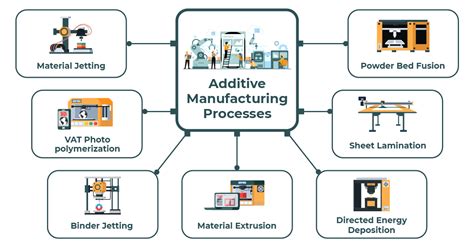

0 · types of additive manufacturing processes

1 · machine learning in additive manufacturing

2 · examples of additive manufacturing processes

3 · additive manufacturing materials list

4 · additive manufacturing machines for sale

5 · additive manufacturing 3d printing machines

6 · additive manufacturing 3d printer

7 · 3d metal printing machine

There is an historical reason for this; it’s all to do with keeping your sword hand free! In the Middle Ages you never knew who you were going to meet when travelling on horseback. Most people are right-handed, so if a stranger passed by on the right of you, your right hand would be free to use your sword if required.

Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material .Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while . For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is . A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.

In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for . Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time . CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production. For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines. While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.

types of additive manufacturing processes

machine learning in additive manufacturing

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material .

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.

CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility.

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production. For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines. While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining.In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material .

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.

examples of additive manufacturing processes

gopro 7 metal housing

The use of corrugated metal in Iceland came about as a response to natural disasters (volcanos, floods, and earthquakes), scarce wood supply (decimated by the Vikings), and catastrophic fires that ravaged the cities.

cnc machine additive manufacturing|types of additive manufacturing processes