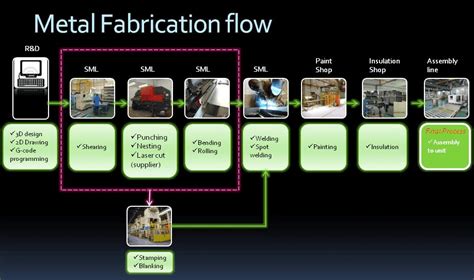

sheet metal fabrication operations What is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. Trenton Sheet Metal Profile and History. Trenton Sheet Metal custom fabricates all types of metal, as well as plasma cutting, shearing, cnc punching, bending, welding, metal cutting, metal stamping and metal rolling.

0 · types of sheet metal forming

1 · sheet metal manufacturing process

2 · sheet metal forming techniques

3 · sheet metal forming processes

4 · sheet metal assembly techniques

5 · how to form sheet metal

6 · curling process in sheet metal

7 · aluminum sheet metal forming

$100.02

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . What is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling.

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .A complete guide on processes, applications, pros, and cons. Discover essential tips and techniques in our comprehensive guide to sheet metal fabrication for both beginners and professionals.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .

1. What is sheet metal fabrication? Sheet metal fabrication is a valuable prototyping and production method for making robust functional parts like panels, brackets, and enclosures.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

Sheet metal fabrication services involve cutting and forming sheet stock using various tools such as shears, lasers, waterjets, plasma, or punch presses. A brake press is commonly used to create angular bends and .

Zetwerk provides high-quality Sheet Metal Components and all secondary operations. Submit the relevant part drawings, 3D files, and other information by clicking on the button below. . The spinning sheet metal fabrication process . Here are some ways leading fabricators are doing so today. 7 Sheet Metal Fabrication Best Practices to stay competitive and improve profitability. Running a sheet metal fabrication shop requires careful planning, . However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing . See also The .Sheet metal design guidelines; Materials; Manufacturing process; Finish operations. Read this article on sheet metal design guidelines before reading these questions and answers. This article will help you to answer below interview questions in a better way. Here is the list of best sheet metal design interview questions with their answers.

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . and the roof are all made from sheet metal that has been cut by laser and punching operations and formed in .

metal electronic enclosures manufacturer

types of sheet metal forming

Summary : Fabrication sheet metal workers, sometimes called precision sheet metal workers, make ducts, gutters, and other metal products. Most work in shops. . stretch forming, axis water jet operation, heat treatment and artificial aging processes, chemical process and primer application. Worked with insulation and sheet metal. Experience . Through controlled mechanical operations, the sheet metal notching process transforms raw material into precisely notched components. Each step builds upon the previous one to ensure consistent, high-quality results. . How Sheet Metal Punching and Notching Operation Compare? Sheet metal fabrication uses punching and notching, yet each .

Overview of Sheet Metal Fabrication. Sheet metal fabrication is essential for various manufacturing processes, ranging from the manufacturing of toys to large-scale airplane parts. Despite its popularity, it is important to know how this manufacturing process works. Here’s a detailed overview of sheet metal fabrication.Drive excellence in your sheet metal fabrication operations with Hitech i2i. Get total control of your shop floor with real-time visibility into every stage of your manufacturing orders. Align your resources with the specific needs of your sheet metal fabrication operations. Our software perfectly meets the needs of small to medium-sized .expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr 0.3-4pts/hr . Drawing – expensive tooling, no net thinning, quick Deep-drawing Shallow-drawing (stamping) Deep-drawing

In this video you will find most of the sheet metal operations with 3D animations

Tim Heston, The Fabricator's senior editor, has covered the metal fabrication industry since 1998, starting his career at the American Welding Society's Welding Journal. Since then he has covered the full range of metal fabrication processes, from stamping, bending, and cutting to grinding and polishing.Sheet metal fabrication Nix Industrial is dedicated to maintaining the highest standards of quality. Our ISO 9001:2015 certification ensures that every project is produced with attention to detail and adherence to internationally recognized quality management practices. This certification reflects our commitment to efficiency, reliability, and continuous improvement—so you can trust that . Sheet metal fabrication can be a fun and rewarding experience, but it is crucial to understand the basics of sheet metal fabrication before you get started. . overlapping cuts to prevent unnecessary material waste and reduce the risk of warping or distortion during cutting operations. Tabs and Bends: Tabs and bends increase part stability .

Definition of sheet metal. While no universally accepted definition of sheet metal exists, industry consensus generally characterizes it as follows: Sheet metal refers to thin, flat metal material, typically less than 6 mm (0.25 .In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post. . Sheet Metal Fabrication. Types of Forging Operations. Following are the main types of .

From cylindrical tanks to architectural cladding, these rolling machines empower fabricators to bring their visions to life. Types of Sheet Metal Rolling Machines. There exists a myriad of sheet metal rolling machines, each tailored to specific applications. Three-roll: The most common type, offering both vertical and horizontal bending .

Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision-driven process transforms flat metal sheets into intricate components. Over the decades, sheet metal manufacturing has evolved from manual . The sheet metal fabrication, and metal mechanics industry as a whole, is one of many thriving manufacturing sectors in Mexico and is an important pillar of the country’s economy. Exports of metal mechanical products in 2017 totaled more than billion, and the sector includes more than 600,000 direct-industry employees.

sheet metal manufacturing process

In this article, you’ll learn the various types of sheet metal operations with their diagrams. In this article, you’ll learn the various types of sheet metal operations with their diagrams. . Tri-State Fabricators. 1146 Ferris Rd. Cincinnati, OH 45102; 513-752-5005; 513-752-2539; [email protected]; Monday - Friday 7:00am - 5:00pm.Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient operations. This comprehensive guide serves as your roadmap to navigating and leveraging this complex process effectively.Sheet Metal Fabrication Services avail the services of cutting out perfect shape and sized portion of the sheet metals which are further used for the construction of several industrial components. These sheet metal services which we use are made up of very tough, tensile and robust quality raw materials which provide these components a long .

Westwood Fabrication & Sheet Metal 1752 Stanley Ave Dayton OH 45404; Phone: 937-837-0494 Fax: 937-837-2704 It is a high-precision welding technique, which makes it suitable for operations with intricate details. The laser beams can focus on the tiniest of substances for extreme accuracy welding. Moreover, . To help you make the most of sheet metal fabrication, we put together this comprehensive guide to the fundamentals of this technique that .Physical Integrity: Electronics are protected against accidental impacts and vibrations that occur during operations. Sheet metal fabrication is also used to manufacture essential components like cable and electrical trays, ensuring proper organization and protection of wiring systems. Precision sheet metal fabrication is a versatile manufacturing process used to create a wide range of components and products with high accuracy and consistency. . We use top-of-the-line machines to run various metal fabrication operations. Our machines perform tried-and-true fabrication methods, such as punching and forming, and more recent .

Contract Manufacturing in Metal Fabrication: 4 Key Reasons Explained; Unlocking Value: The Benefits of Custom Sheet Metal Fabrication; 5 Key Considerations for Creating a Sheet Metal Prototype; A Guide for Minneapolis Businesses to Successfully Set Sheet Metal Fabrication Goals for the New Year; The Environmental Sustainability of Laser Cutting

metal enclosure box singapore

16"x 6.7" Treestands Footrest Kit, Heavy Duty Metal Climbing Treestand Platform Footrest Kit for 0.8"-1" Square Tube Bracket, Climbing Tree Stand Accessories for Outdoor Hunting Standing Safety

sheet metal fabrication operations|sheet metal forming techniques