u bending sheet metal Sheet metal bending has distinct advantages over alternative sheet metal fabrication processes, including higher output, lower cost and high flexibility in design. It also removes many difficulties associated with assembly techniques . Example of a large trendy eat-in kitchen design in Florence with a drop-in sink, flat-panel cabinets, white cabinets, stainless steel countertops, metallic backsplash, stainless steel appliances and an island.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

White House Black Market offers polished black and white women's clothing with pops of color and patterns. Shop tailored dresses, tops, pants and accessories.

types of bending sheet metal

Die Basics 101: Rotary and reverse U bending. Part XV of this series described several bending methods—wipe, coin, relief, pivot, and V. It also discussed springback and how to compensate for it when using these .

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .Sheet metal bending has distinct advantages over alternative sheet metal fabrication processes, including higher output, lower cost and high flexibility in design. It also removes many difficulties associated with assembly techniques .

Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal .Channel bending uses a shaped punch and die to form a sheet metal channel. A U bend is made with a U shaped punch of the correct curvature. Figure:269 : Many bending operations have been developed to produce offsets and form . U-bending. In this type of a bending operation, in which when the punch is pressed by a force to move into the die, the sheet metal piece gets formed into a U-shape. 4. Offset Bending. It is a type of bending operation, in which a piece of sheet metal is formed into an offset shape with the help of a punch and die. .Our Metal U-Channels, are crafted with precision and strength in mind. . B&B Sheet Metal is a leading manufacturer of exterior architectural sheet metal products in the northeast. We are known for our attention to detail, our design capabilities, our competitive pricing and our lead time on all our projects. . Heavy Guage Metal Bending .

sheet metal bending standards

Bending sheet metal parts is a process that is completed by utilizing press brakes and our very skilled press brake operators. At Approved Sheet Metal, we can hold tolerances of +/- 1 degree on most bend angles. The ideal bend radius on formed parts is 0.030 in., this ensures that you can get consistent, quality parts that will maintain solid .Sheet metal bending, particularly when it comes to bending U-channel flanges, is a critical process in manufacturing and fabrication industries. It involves the plastic deformation of the sheet metal over an axis to create a desired geometric shape, often used to impart strength, stiffness, and aesthetic appeal to the final product. Learn more here:https://www.wilsontool.com/Products/Bending/American-Precision/Special/ChannelWatch how this custom press brake channel .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. 7. Joggle Bending. Joggling or segmented bending is shaping a sheet metal section by section using stringers and formers. The technique is especially helpful when there is a need to bend an extended workpiece in a periodically repeated pattern. The working principle of the method is pushing a sheet metal workpiece in an equipment unit or a brake.

Not everything requires a brake; there are lots of other ways to bend sheet metal, especially if it’s a smaller piece. One way that I often work with sheet metal for automotive panels is to sandwich 2×4’s in a vise with the workpiece in the middle, then work the metal with a rubber mallet. The nice thing with this is that you can use .

The only problem with the pan brake is that I can only bend the metal at a wide thickness of 1.5" thick. I can not make thin U channels. This would be ideal for a press brake but I do not want to invest a ton of money in a heavy duty one. The sheet metal I am forming is 20 gauge. I am using 24" long sheet metal stock cut into 4" thick pieces. U-Bending. U-bending uses a U-shaped punch and die to bend metal sheets into a U shape, not a V shape like V-bending. This is important when precise bending of the sheet metal is required, especially when the end product needs to enclose or house other parts. By using U-shaped tooling, you ensure the bent metal sheet is uniform along the bends . Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum .

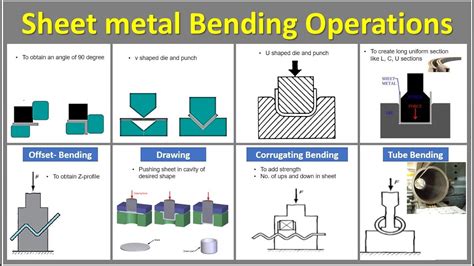

The purpose of sheet metal bending methods is to shape sheet metal into its intended forms. Multiple factors play a role in deciding which sheet metal bending method is optimal for a given project. These factors include the thickness of the sheet metal, the bend radius, the overall size of the bend, and the desired use. Sheet metal bending is a deformation process that uses a machine called a brake to bend metal. Metal can be bent into U shapes, V shapes, or channel to an angle of up to 120 degrees. 331-223-4378 [email protected]

2.4 Two-ply sheet reverse-bending It is assumed that in sheet reverse stretch–bending, (a) in each layer, the stretching force is uniform and keeps constant, and (b) the sheet thickness remains unchanged. During punch movement, the sheet is initially stretched and bent around the die radius, then unbent due to leaving the contact surface. There are several specific methods of sheet metal bending, including each of the following: V-bending. The most popular type of sheet metal bending is called V-bending, which involves bending the material into something of a “V” shape. The key piece of equipment here is a punch and v-die, which is used to create the shape.

Solidworks Animation Tutorial: Sheet Metal U BendingThe Tutorial Consists of :1. Die and Punch Design2. Assembly (the most crucial part) 3. AnimationSince th.

sheet metal bending near me

First we cut the metal part out of a huge sheet of metal. It is so exact so please, make sure your measurements are accurate. Then we might bend it Depending on the shape you have chosen, we need to bend the sheet metal, once, twice or even three or four times. Then sometimes, we need to weld it. And always we will send it. In sheet metal bending, you work a flat metal piece by applying a force that deforms it along a straight axis. The result is an angular change in shape allowing you to form curved and angled parts. When bending sheet metal, you consider bend .U Bending - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses various methods for bending sheet metal, including: 1. U-bending requires a punch, die, and pressure pad to hold the workpiece during bending. Spring-actuated plungers and hook strippers can also be used for stripping. 2. Positive knock-off uses a spreader plate to . That s why; in this study, the optimum bend radii were (R) determined using the Finite Element Analysis (FEA) based on the sheet metal thickness (T) in order to compensate for the springback to .

Sheet Metal and Plastic Bending Calculator. . If you’re utilizing 3D CAD software, d raw the part with the flanges in place using the sheet metal function in whatever CAD software you are using. Once you have the flanges in place, edit the bend radius to match the advanced details found at the bottom of the bending calculator. .The u-bend test is a method for the determination of the ductility of sheet metals and is used to test finishes and coatings. Testing the Coating A u-shape specimen is drawn from a coated metal strip and the coating adhesion is determined with the use of an adhesive tape.GL Engineering Works - Offering U Bending Die, For Sheet Metal Part at Rs 35000 in Faridabad, Haryana. Get Bending Dies at lowest price | ID: 20098219233

sheet metal bending guidelines

corrugated metal sheeting

A junction box is a standard electrical box that contains two or more spliced electrical cables. The box must have a removable, accessible cover. Junction boxes can be .

u bending sheet metal|sheet metal bending guidelines