sheet metal fabrication techniques pdf Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .

WSM Industries is the leader in heating, ventilation and air conditioning supplies. We manufacture pipe, duct, spiral pipe and fittings, and carry a comprehensive supply of flat sheets, venting, registers and grills, insulation supplies, and Ducane equipment and linesets.

0 · sheet metal handbook free download

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guideline pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal bending guide pdf

Diébédo Francis Kéré is one of the most celebrated African architects of recent times, and his uniquely informed, sustainable designs are leading the global conversation around the future of considered constructions.

sheet metal handbook free download

From the production of computers to the construction of airplanes, sheet metal fabrication is a crucial component in producing materials, parts, and components. Sheet metal fabrication .

sheet metal fabrication handbook pdf

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of .

Introduction. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage - High strength, .DESIGN TIPS. OFFSET. Whenever possible, maintain minimum spacing of 2-2.5x raw material thickness from edge of cutout to bend radius tangency. Lesser spacing requires secondary .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on .

Learn about the latest technology and techniques for cutting, bending, and finishing sheet metal projects with precision and efficiency. Master the art of sheet metal fabrication with our comprehensive handbook. Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines .

sheet metal die design pdf

sheet metal design handbook pdf

scythe metal coin box legendary box

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000.

1.0 INTRODUCTION Sheet metal fabrication process In fabrication, sheet metal refers to thin, flat pieces of metal that are commonly used to create a wide variety of parts, structures, and products. The thickness of sheet metal typically ranges from 0.002 inches (0.05 mm) to several millimeters, though thicker materials are sometimes referred to as plate metal.

Ready to tackle your next metalworking project? In this video, we reveal essential techniques for DIY metal cutting, whether you're working with sheet metal,.Every metal fabrication process comprises three major steps: design, fabrication, and installation. The resulting components of metal fabrication are found in everyday items such as computers, smartphones, tools, and cars, as well as high-performance, mission-critical applications the likes of aircraft. Here are some of the common types of .

In addition, sheet metal manufacturers can use sheet metal fabrication techniques to produce extremely high-quality, durable parts and structures. Versatility and availability of options: Sheet metal fabrication has various capabilities and characteristics that make it a highly versatile manufacturing process. This process can create standalone . Metal fabrication : a practical guide by O'Con, Robert L. Publication date 2015 Topics Metal-work, Travail des métaux, metalworking, Metals Forming Publisher . Pdf_module_version 0.0.18 Ppi 360 Rcs_key 24143 Republisher_date 20220629024201 Republisher_operator [email protected] .

The sheet metal materials we specialize in are carbon steel, stainless steel, aluminum, brass, copper, and various other types of sheet metal substrates. Our team of experts utilizes your AutoCAD, IGES, PDF, or SolidWorks file as a starting point to manufacture custom OEM parts with precise tolerances, ensuring that they consistently meet your .7 Sheet and plate metalwork 277 7.1 Sheet and plate metalwork (introduction) 278 7.2 Roll-bending sheet metal and plate 296 7.3 Flow forming sheet metal 301 7.4 The principles of metal spinning 318 7.5 Swaging sheet metal 324 7.6 Basic fabrication procedures 330 Exercises 345 8 Structural steelwork and pipework 347Sheet Metal Fabrication Eddie Paul,2008-03-15 Sheet metal fabrication--from fins and fenders to art--with all the necessary information on tools, preparations, materials, forms, mock-ups, and much more. Professional Sheet Metal Fabrication Ed Barr,2013-04-15 Professional Sheet Metal Fabrication is the number-one resource for sheet metal

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which . A .pdf drawing can be attached to the uploaded model if further specifications are required. Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, .Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal.

A sheet metal tool development results from an ingenious use of a large number of manufacturing technologies, both using state-of-the-art automated processes and long-established metalwork, often . Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. Close; Articles Metalworking. Bending/Folding; Shearing; Grooving; Roll Forming; Punching; Stamping; . In this article, we delve into essential tips for sheet metal design, exploring techniques. Fabrication is not a single-shot process. It is a combination of different tools, processes, and techniques. So, manipulating a raw sheet into final shapes involves different sheet metal fabrication techniques, from cutting to .

expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . %20can.pdf Deep Drawing of drinks cans . Hydro-forming – cheap tooling, no net thinning, slow(ish), high formability Low volume batches .

1. Interpreting metal fab drawings . Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and

Recommended for: Beginner & Advanced Sheet Metal Workers Professional Sheet Metal Fabrication is another successful book by Ed Barr. This is the bestselling predecessor to Sheet Metal Shaping, where the author describes the basic concepts to start fabricating sheet metal and completing projects.. The start-to-finish aspect of the information covered in this .View 03 Sheet Metal Basic.pdf from EIE EIE3109 at Hong Kong Polytechnic University. Sheet Metal & Welding IC348 Appreciation of Manufacturing Processes IC348 Sheet Metal & Welding rundown >Day 1 -

Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. The thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. CommonlySheet metal fabricators also have these same choices. The most significant choice involves coatings such as plating or powder coating. In many cases, the cost of the equipment is simply too much given the small amount of customer requirements for the coating. In other cases, the EPA requirements or theSheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Various special tools are used in this process to convert sheet metals into useful components by minimal efforts. It is a value-added process to create machines, structures, or component parts following engineering drawings which usually serves as the .

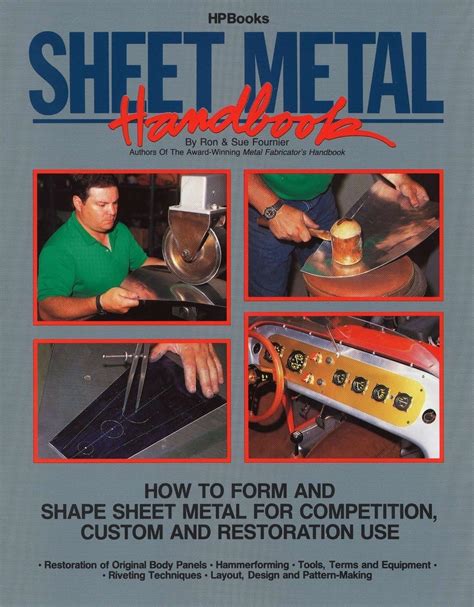

These are just a few of the many tips and techniques shared by master metal craftsman Ron Fournier. Author of HP's award-winning Metal Fabricator's Handbook, Fournier packs decades of experience designing and shaping sheet metal components for Indy cars, drag race cars, road racers, street rods and street machines into 144 pages.Chapter 6.Formulas for Sheet Metal Layout and Fabrication 6.1 6.1 Sheet Metal Flat-Pattern Development and Bending / 6.8 6.2 Sheet Metal Developments,Transitions,and Angled Corner Flange Notching / 6.14 6.3 Punching and Blanking Pressures and Loads / 6.32 6.4 Shear Strengths of Various Materials / 6.32 6.5 Tooling Requirements for Sheet Metal .Lean over to keep the weld pool in view. 51 SPECIAL TECHNIQUES FOR WELDING SHEET METAL Once you feel that the machine is properly set up to run a continuous bead on thicker metal, clamp two pieces of your chosen sheet metal together in anticipation of creating a butt joint. Leave a gap between the pieces equal to a little more than the . Sheet Metal Fabrication: Techniques and Tips for Beginners and Pros covers the necessary tools and how to use them; how to choose, prepare, and work with the most suitable material; how to make bucks, plugs, and mock-ups; and how to cut, bend, form, and join sheet metal. Whether you want to shape a fender for a custom car, re-create damaged .

a1 - SHEET METAL PLANT. 100,000 SQUARE FEET FACILITY. Our On-stop-shop started operations since 2015 providing Sheet metal fabrication, welding, powder coat (up to 2,100 salt spray hours) and final assemblies to customers in Northern Mexico and USA. This facility is located in Monterrey, Mexico; only 138 miles from the U.S. border.

sheet metal design guideline pdf

sheet metal design calculations pdf

The question is, "Does every metal box need to be grounded via a screw in the hole in the back of the box?" For safety, yes. .in addition to the ground terminal of the .

sheet metal fabrication techniques pdf|sheet metal fabrication handbook pdf