checking continuity of an junction box The most accurate way to verify whether or not there a proper ground connected, would be to check for continuity between the junction box and the grounding electrode system. In most . Standard Die International is a full-service precision metal stamping & deep drawn parts company for a growing list of industries. Get a free quote today! (800) 838-5464

0 · testing continuity with multimeter

1 · multimeter continuity readings

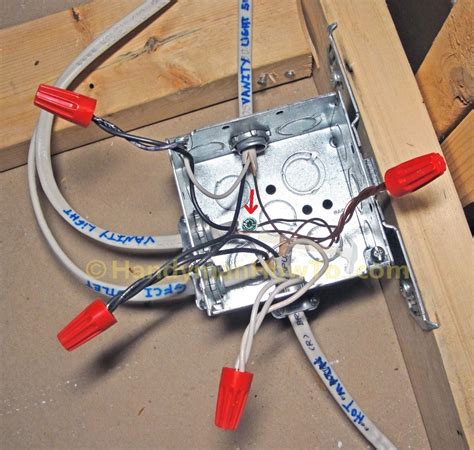

2 · metal junction box wiring diagram

3 · metal junction box voltage reading

4 · metal junction box not charging

5 · junction box wiring problems

6 · how to test continuous wire

7 · how to check for continuity

D&H Industries are experts at producing high-quality, precision metal stampings for leading OEMs across various industries. Our 200, 1000, and 2,000-ton hydraulic press are capable of deep drawing up to 11 inches in both light and .

You can't use a voltmeter to check the box by putting one of your probes to one side of the box and one on the other side. You need to kill all power to the electrical circuits in the box and using you continuity tester to "ring out" which hot wire is going to ground at the box.The most accurate way to verify whether or not there a proper ground connected, would be to check for continuity between the junction box and the grounding electrode system. In most .

To test continuity, all you have to do is stick 2 terminals on your multimeter against 2 ends of an electrical current. Testing continuity in a wire, current, or fuse is a good idea if . To test your fixtures, use a multimeter for voltage testing. And to measure AC voltage, set your multimeter to 200 volts. Make a note of the reading. The fixture is good if the .

Visual Inspection: Start by visually inspecting the wiring within the junction box for any obvious signs of damage or errors, such as loose connections or exposed conductors. Check Continuity: Use a multimeter to .There are mainly two methods for checking the continuity of a circuit using a multimeter. The first method is to use the continuity mode in the multimeter, which is specially made for this purpose. The second method is to use the Ohmmeter . Check continuity. If you have a circuit tester, you can use it to determine if the box is grounded. Set your meter to beep when it finds continuity and touches one wire from this box with each prong of the tester, testing for an .If you've 100% ruled out all known junction boxes then you need to narrow down the problematic section of cable and go hunting between with a cable tracer. With each section of wiring (ie: .

Check Continuity: Ensure that all wires have proper continuity and there are no breaks in the wiring. Inspect for Corrosion : Look for signs of corrosion on the wire .

You can't use a voltmeter to check the box by putting one of your probes to one side of the box and one on the other side. You need to kill all power to the electrical circuits in the box and using you continuity tester to "ring out" which hot wire is going to ground at the box.

Testing for continuity is an easy and reliable way to determine whether a switch or outlet has internal damage. If you're using a multimeter, set it to the "Continuity" function, or select a midrange resistance setting, in ohms.The most accurate way to verify whether or not there a proper ground connected, would be to check for continuity between the junction box and the grounding electrode system. In most situations this is not an option, so another test must be performed. To test continuity, all you have to do is stick 2 terminals on your multimeter against 2 ends of an electrical current. Testing continuity in a wire, current, or fuse is a good idea if you’re installing or repairing any electrical components in an outlet, fuse box, car, or appliance. To test your fixtures, use a multimeter for voltage testing. And to measure AC voltage, set your multimeter to 200 volts. Make a note of the reading. The fixture is good if the voltage is close to 120 volts. A continuity test can be used to determine the resistance between light fixture connectors.

Visual Inspection: Start by visually inspecting the wiring within the junction box for any obvious signs of damage or errors, such as loose connections or exposed conductors. Check Continuity: Use a multimeter to test for continuity between wire connections. Lack of continuity indicates a faulty or incomplete connection that needs to be addressed.There are mainly two methods for checking the continuity of a circuit using a multimeter. The first method is to use the continuity mode in the multimeter, which is specially made for this purpose. The second method is to use the Ohmmeter . Check continuity. If you have a circuit tester, you can use it to determine if the box is grounded. Set your meter to beep when it finds continuity and touches one wire from this box with each prong of the tester, testing for an audible beep.If you've 100% ruled out all known junction boxes then you need to narrow down the problematic section of cable and go hunting between with a cable tracer. With each section of wiring (ie: junction box to next junction box), test continuity of the cable.

Check Continuity: Ensure that all wires have proper continuity and there are no breaks in the wiring. Inspect for Corrosion : Look for signs of corrosion on the wire connections. Corroded connections should be cleaned or replaced as necessary. You can't use a voltmeter to check the box by putting one of your probes to one side of the box and one on the other side. You need to kill all power to the electrical circuits in the box and using you continuity tester to "ring out" which hot wire is going to ground at the box. Testing for continuity is an easy and reliable way to determine whether a switch or outlet has internal damage. If you're using a multimeter, set it to the "Continuity" function, or select a midrange resistance setting, in ohms.

The most accurate way to verify whether or not there a proper ground connected, would be to check for continuity between the junction box and the grounding electrode system. In most situations this is not an option, so another test must be performed. To test continuity, all you have to do is stick 2 terminals on your multimeter against 2 ends of an electrical current. Testing continuity in a wire, current, or fuse is a good idea if you’re installing or repairing any electrical components in an outlet, fuse box, car, or appliance. To test your fixtures, use a multimeter for voltage testing. And to measure AC voltage, set your multimeter to 200 volts. Make a note of the reading. The fixture is good if the voltage is close to 120 volts. A continuity test can be used to determine the resistance between light fixture connectors.

Visual Inspection: Start by visually inspecting the wiring within the junction box for any obvious signs of damage or errors, such as loose connections or exposed conductors. Check Continuity: Use a multimeter to test for continuity between wire connections. Lack of continuity indicates a faulty or incomplete connection that needs to be addressed.There are mainly two methods for checking the continuity of a circuit using a multimeter. The first method is to use the continuity mode in the multimeter, which is specially made for this purpose. The second method is to use the Ohmmeter .

testing continuity with multimeter

multimeter continuity readings

Check continuity. If you have a circuit tester, you can use it to determine if the box is grounded. Set your meter to beep when it finds continuity and touches one wire from this box with each prong of the tester, testing for an audible beep.

If you've 100% ruled out all known junction boxes then you need to narrow down the problematic section of cable and go hunting between with a cable tracer. With each section of wiring (ie: junction box to next junction box), test continuity of the cable.

metal junction box wiring diagram

metal junction box voltage reading

metal junction box not charging

There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that .

checking continuity of an junction box|metal junction box wiring diagram