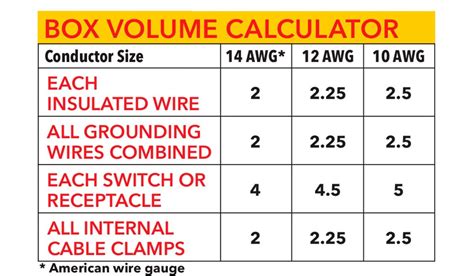

electrical box in section dimensions Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines . Understanding and preventing welding defects is crucial not only for the durability of your welds but also for safety. Weld defects can weaken joints, leading to the potential failure of the entire weldment. In extreme cases, this leads to severe consequences.

0 · standard size electrical box

1 · standard electrical box size chart

2 · indoor surface mount electrical box

3 · electrical metal box size chart

4 · electrical box wire size chart

5 · electrical box size chart

6 · electrical box dimensions standard

7 · dimensions of electrical outlet box

Most of my projects use either 1x1 or 1x2 square tubing, either 16ga or 14ga. For the skin, I usually use 20ga or 22ga sheet. On past projects, I have tried a few different methods. #2 is the easiest (I have a bench punch), but it leaves the edge of the sheet metal exposed. I would like to make the edge of the sheet metal blend in with the tubing.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . In the following sections, we will discuss the standard sizes of electrical boxes commonly used in residential and commercial settings, along with their specific applications and features. Understanding the standard sizes of .Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines . According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal .

Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box .Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this .Section 370.16 outlines requirements for sizing boxes containing conductors 6 AWG or smaller. Remember, specific dimensions are used to calculate the box size. Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be .

Electrical boxes come in metal and plastic and in a wide range of shapes and sizes. Choosing the right size is important because it's unsafe—and illegal—to cram too many wires and devices into a box. Both plastic and metal . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. In the following sections, we will discuss the standard sizes of electrical boxes commonly used in residential and commercial settings, along with their specific applications and features. Understanding the standard sizes of electrical boxes .

standard size electrical box

Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box.

According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula: \footnotesize L_\text {min} \geq 8 \times t_\text {max} Lmin ≥ 8 × tmax. where:Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.

Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.Section 370.16 outlines requirements for sizing boxes containing conductors 6 AWG or smaller. Remember, specific dimensions are used to calculate the box size. Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be necessary to perform box-fill calculations. These are covered in National Electrical Code (NEC) sections 314.16(A) and 314.16(B). Electrical boxes come in metal and plastic and in a wide range of shapes and sizes. Choosing the right size is important because it's unsafe—and illegal—to cram too many wires and devices into a box. Both plastic and metal electrical boxes are suitable for most household projects.

standard electrical box size chart

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. In the following sections, we will discuss the standard sizes of electrical boxes commonly used in residential and commercial settings, along with their specific applications and features. Understanding the standard sizes of electrical boxes .

cnc machine to make wooden signs

Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box. According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula: \footnotesize L_\text {min} \geq 8 \times t_\text {max} Lmin ≥ 8 × tmax. where:

Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.Section 370.16 outlines requirements for sizing boxes containing conductors 6 AWG or smaller. Remember, specific dimensions are used to calculate the box size.

Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be necessary to perform box-fill calculations. These are covered in National Electrical Code (NEC) sections 314.16(A) and 314.16(B).

indoor surface mount electrical box

electrical metal box size chart

electrical box wire size chart

electrical box size chart

I own it's bigger brother, but have run a buddy's Square Wave 175 a fair amount. They're a good, solid TIG power source with very little in the way of extra features. If you're going to be welding a lot of aluminum, I would look at something with a little more in the way of AC controls, but this will definitely do the job.

electrical box in section dimensions|standard electrical box size chart