sheet metal flat pattern calculator Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This . WASHINGTON — The U.S. Army has launched an effort to replace Stinger missiles with a next-generation interceptor for Short-Range Air Defense capability as the aging weapon system heads toward.

0 · sheet metal flat pattern layout

1 · sheet metal flat pattern formula

2 · sheet metal flat length calculation

3 · sheet metal flat layout calculator

4 · sheet metal bending calculator free

5 · flat pattern layout calculator

6 · calculate k factor sheet metal

7 · blank size calculator sheet metal

$5.98

sheet metal flat pattern layout

Calculate the increase in sheet metal length due to bending using k factor and flange length. Enter the material, bending, and flange details and get the results for bend deduction and flat pattern.K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a . Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This . Use SendCutSend’s bending calculator to input your desired material .

This calculator provides the calculation of flat pattern calculation for sheet metal fabrication. Explanation. Calculation Example: The flat pattern calculation (FPC) is used in .Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Effortlessly calculate K-Factor for sheet metal bending with our free online calculator. Save time and improve accuracy. Try it now!

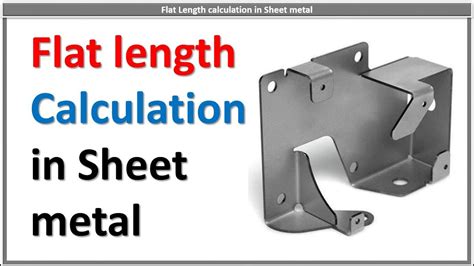

K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. Bend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the bending process.With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to .

The Sheet Metal Flat Pattern Calculator is a comprehensive tool designed for engineers, fabricators, and designers who need quick and accurate flat pattern layouts for a variety of complex shapes and transitions. This app simplifies .Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material. The layout may either be done on the material . Flat Pattern Area Calculation. This calculator provides the calculation of the flat pattern area of a sheet metal part. Explanation. Calculation Example: The flat pattern area is the area of the sheet metal before it is bent or formed into a three-dimensional shape. It is important to calculate the flat pattern area accurately in order to avoid .

Cone Calculator is helpful for Generating Flat Pattern Layout or Fabrication Layout of all types of cones. This Calculator gives a complete solution to all types of Cones Fabrication Layout. You Can save the Cost of Material by using this calculator. You can Save Time on your Fabrication Layouting process.K Factor Calculator This calculator can be used for calculating k factor in sheet metal using reverse engineering method. Sheet Thickness, Material and machine affect the value of K Factor. K Factor Calculator Sheet Metal Flat Length Calculator Sheet Metal Flat Length can be calculated with this calculator. This calculator can be used for number [.]

The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . Flat Pattern Degrees: degrees .

It’s used to calculate the flat pattern length. Why is K factor important in sheet metal? The K factor is crucial in sheet metal bending because it helps determine the accurate flat pattern length, which is essential for cutting and forming sheet metal parts to the correct dimensions. How do you calculate the flat length of sheet metal?

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Skip to content. Request a Quote (916) 419-0580; . " should be subtracted from the flat pattern so the formed part arrives at the desired dimensions. Because a bend deduction can be measured in a .

Several terms are at the heart of any sheet metal bending operation, including the neutral axis, inside bend radius, outside setback (OSSB), and bend allowance (BA). You calculate the bend deduction by doubling the OSSB and subtracting the BA. . You can apply all this in two different ways to your flat pattern layout. One way subtracts the BD . To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required (Inside Diameter + Thickness) x .Sheet Metal Calculator. This tool calculates the weight of sheet metal based on the specified parameters. Please fill in the form fields: Metal Type: . Estimate the flat pattern size for sheet metal parts based on the finished part dimensions and bend allowances. Input the final part dimensions and bend allowance to get the flat pattern size . A fundamental principle derived from the neutral layer concept is that the unfolded (flat pattern) length of a bent sheet metal part equals the length of the neutral layer. This can be mathematically expressed as: Unfolded length = straight length A + straight length B + arc length C. Where: A and B are the straight sections of the part

Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): Bend radius (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank diameter (in): Punch diameter (in): Ultimate tensile strength (psi): Factor of safety: Drawing ratio:

sheet metal flat pattern formula

For creating a cone from sheet metal or any flat material. Added the function of saving the development of a straight and truncated cone to a DXF file. Export the flat pattern as a dxf file, then you can open it with any CAD program like Acad. You can use the dxf file to cut the sheet on a laser or cnc machine. For creating a cone from sheet metal or any flat material. Added the function of saving the development of a straight and truncated cone to a DXF file. Export the flat pattern as a dxf file, then you can open it with any CAD .

Overlap Normally, the flat pattern dimensions are are exact and dont have any extra material for overlapping the edges. If you want extra material on the edges of the cone then add here. The material is added evenly along the edge. If you .K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the . The calculator generates DXF files that include two layers, one with the flat or unfolded pattern, and the other with a 3D wire-frame model of the transition. These are opened in the 2D software . Calculator will calculate the necessary dimensions for the construction flat pattern segments lobsterback bend, elbow , tee piece, frustum cone and truncated pipe, truncated cone with an accessible vertex and triangulation method, Truncated Pipe Layout or Pipe cut at any angle Flat Pattern, Pipe to Cone intersection at Perpendicular to Axis Flat Pattern, Pipe .

In Sheet Metal or Fabrication Industry Flat Pattern making is useful for forming various shapes such as Conical Shapes, Box Shapes, Pipe Shapes, Transition Shapes such as Square to Round or Round to Square, or any complex shapes used for various applications in various Industry. . Previous Post Fabrication Flat Pattern Calculator App By Let .Layer 2Dref is the same, with auxiliary lines, to help bending or folding the sheet metal patterns into finished metal entities: 2D MESH; color red; Layer txt is for the texts, as name of the pattern, pattern calculation date, user parameter input, user settings at that moment; and annotations of number of flat pieces and its thickness Sheet Metal Square to Round Calculator Square Width (in inches): . Flat Pattern Development (in inches): FAQs. How do you calculate square to round? The calculation for converting a square shape to a round shape depends on the specific dimensions and requirements of the conversion. In general, you would need to determine the side length of .

Since 2011 FLAT METAL PATTERNS has been observing the insolation industry community. On January 19, 2016 we decided to undertake this project as we saw the need to provide more knowledge to those in this industry to make a profit. Our . At this point, I can leverage this value in SOLIDWORKS to get accurate sheet metal flat patterns. SOLIDWORKS will then subtract this amount of material per bend giving me the most accurate flat pattern as possible. This information would need to be calculated for each thickness, angle and bend radius (if you are using multiple punch radii). .The fact that you can take the software out "on the corner of the table" as you would take out a calculator on your smartphone is an incredible asset to be used on workshop and sites. Flattening files generated by MetalFox can be read by Solidworks, Autocad and all CAD softwares. . an operation which consists in defining the “patterns” of .

Welcome to dxfcreator.com. The website for online creation of flat pattern sheetmetal parts and generation of DXF files of these sheetmetal parts, all this without using CAD software and within a very short space of time. A preview of the sheet metal will be displayed once the requested parameters have been entered.

I've been in tool and die, sheet metal shearing, cutting and forming for years. Using this app is easier than relying on my memory! 4 people found this review helpful. . Flat Pattern Bend Calculator. S.E. 4.5 star. Metal Bending Calculator. S.E. 3.9 star. Flat pattern cone calculator. S.E. 4.5 star. Tank Volume Calculator. S.E. 4.4 star. Pipe .

whats the box metal gear solid

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly distribute the wastewater into the leach field.

sheet metal flat pattern calculator|flat pattern layout calculator