difference between cnc and milling machine Generally, CNC routers are designed to cut softer materials. However, softer materials can fall under a wide range – wood, plastic, and even softer metal, like aluminum. . Sigma's weatherproof round extension ring increases the capacity of a weatherproof box. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations. Extension rings are powder coated for corrosion resistance and include closure plugs, hardware and gasket.

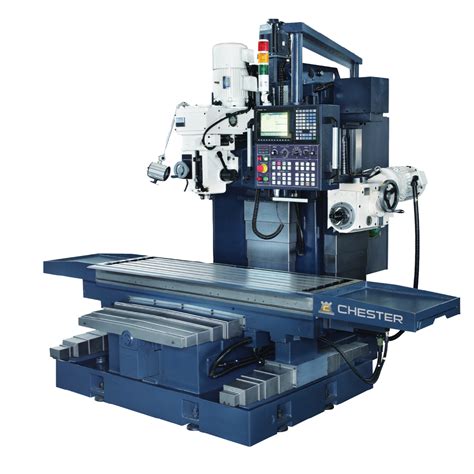

0 · types of cnc milling machines

1 · most affordable cnc milling machines

2 · cnc milling machine pdf

3 · cnc milling machine near me

4 · cnc milling machine description

5 · cnc milling machine definition

6 · best milling machine for small shop

7 · affordable cnc milling machines

$148.99

Because of how they are designed, CNC milling machines will always be the better choice for machining industrial-grade hard materials, while CNC routers will work well on wood, acrylic, and soft metals. CNC routers and CNC milling machines perform similar standard tasks in significantly different ways. The first step is understanding the difference between these two machines to choose the best one for your applications. The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall .

Here’s a breakdown of the key differences between CNC turning and milling: CNC Turning: In turning, the workpiece rotates while the cutting tool remains stationary, and material is removed from the workpiece’s outer diameter to create . Generally, CNC routers are designed to cut softer materials. However, softer materials can fall under a wide range – wood, plastic, and even softer metal, like aluminum. .While CNC machines can handle large-scale orders, manual machines can fill in smaller orders requiring simpler parts. If setting up your CNC machine and writing the code for it would take more time than simply machining the part yourself, . Put simply, the difference between the two processes comes down to which part moves – in general terms, the metal or the machine. With CNC turning a metal bar is fed into the lathe and rotates at speed while a single .

CNC Milling In milling, the work material is held stationary and the cutting tool revolves to remove material in up to 5 axes. Some examples of parts include structural type components (e.g., mounting plates) and parts with 3D forms . Put simply, the difference between CNC turning and milling is which part actually moves – the machine itself or the raw material. CNC milling processes involve the material being held in place while the cutting tools . CNC Router vs. Mill: How They Work. Both a CNC router and mill create parts by removing material from a piece, also known as subtractive manufacturing. This process is different from CNC machines, such as 3D printers, that add materials to create a shape or part. Because of how they are designed, CNC milling machines will always be the better choice for machining industrial-grade hard materials, while CNC routers will work well on wood, acrylic, and soft metals.

CNC routers and CNC milling machines perform similar standard tasks in significantly different ways. The first step is understanding the difference between these two machines to choose the best one for your applications. The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall material blocks, and are more rigid and accurate since they move the table, not the workpiece.

Here’s a breakdown of the key differences between CNC turning and milling: CNC Turning: In turning, the workpiece rotates while the cutting tool remains stationary, and material is removed from the workpiece’s outer diameter to create cylindrical shapes. Generally, CNC routers are designed to cut softer materials. However, softer materials can fall under a wide range – wood, plastic, and even softer metal, like aluminum. Meanwhile, milling machines are made to cut metal. Milling machines can cut any metal, from soft aluminum to hard titanium.While CNC machines can handle large-scale orders, manual machines can fill in smaller orders requiring simpler parts. If setting up your CNC machine and writing the code for it would take more time than simply machining the part yourself, manual machining becomes more efficient.

Put simply, the difference between the two processes comes down to which part moves – in general terms, the metal or the machine. With CNC turning a metal bar is fed into the lathe and rotates at speed while a single-point cutting tool removes portions of the metal to create the desired shape.CNC Milling In milling, the work material is held stationary and the cutting tool revolves to remove material in up to 5 axes. Some examples of parts include structural type components (e.g., mounting plates) and parts with 3D forms (e.g., mold cavities). Put simply, the difference between CNC turning and milling is which part actually moves – the machine itself or the raw material. CNC milling processes involve the material being held in place while the cutting tools rotate around it.

CNC Router vs. Mill: How They Work. Both a CNC router and mill create parts by removing material from a piece, also known as subtractive manufacturing. This process is different from CNC machines, such as 3D printers, that add materials to create a shape or part.

Because of how they are designed, CNC milling machines will always be the better choice for machining industrial-grade hard materials, while CNC routers will work well on wood, acrylic, and soft metals. CNC routers and CNC milling machines perform similar standard tasks in significantly different ways. The first step is understanding the difference between these two machines to choose the best one for your applications.

The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall material blocks, and are more rigid and accurate since they move the table, not the workpiece.

Here’s a breakdown of the key differences between CNC turning and milling: CNC Turning: In turning, the workpiece rotates while the cutting tool remains stationary, and material is removed from the workpiece’s outer diameter to create cylindrical shapes. Generally, CNC routers are designed to cut softer materials. However, softer materials can fall under a wide range – wood, plastic, and even softer metal, like aluminum. Meanwhile, milling machines are made to cut metal. Milling machines can cut any metal, from soft aluminum to hard titanium.While CNC machines can handle large-scale orders, manual machines can fill in smaller orders requiring simpler parts. If setting up your CNC machine and writing the code for it would take more time than simply machining the part yourself, manual machining becomes more efficient.

northshore sheet metal

Put simply, the difference between the two processes comes down to which part moves – in general terms, the metal or the machine. With CNC turning a metal bar is fed into the lathe and rotates at speed while a single-point cutting tool removes portions of the metal to create the desired shape.CNC Milling In milling, the work material is held stationary and the cutting tool revolves to remove material in up to 5 axes. Some examples of parts include structural type components (e.g., mounting plates) and parts with 3D forms (e.g., mold cavities).

types of cnc milling machines

most affordable cnc milling machines

Buy Weatherproof Junction Boxes at Screwfix.com. Protect exterior electrical wiring and connections from damage. Weather and dust resistant. Free returns.

difference between cnc and milling machine|cnc milling machine definition