overhead sheet metal weld Following these step-by-step guidelines on how to weld overhead can help you successfully weld overhead and achieve strong, reliable welds. Remember to always prioritize safety and seek professional guidance if needed. $1,200.00

0 · welding overhead positions

1 · welding overhead cost

2 · welding overhead

3 · welding in overhead arc

4 · overhead welding instructions

5 · overhead fillet welding

6 · overhead arc welding problems

7 · overhead arc welding angle

Get the best deals on Metal Jewelry Boxes when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

If you need to weld overhead or out of position, be sure your filler metal is capable of that and then dial in your weld parameters to help optimize out-of-position welding. To learn more about the five basic types of weld joints, .

Following these step-by-step guidelines on how to weld overhead can help you successfully weld overhead and achieve strong, reliable welds. Remember to always prioritize safety and seek professional guidance if needed. Sheet metal welding is a vital aspect of sheet metal fabrication. Read on to understand the welding methods and tips for the sheet metal parts. . This means you won’t get a clean arc, and you’ll end up with a poor-quality .Massive projects require proper and intricate planning. Cost estimation is usually a core aspect during the planning process. At the same time, you will have to clearly specify the needs of the project, especially if it will involve specially . Groove weld. Flat Surface. In sheet metal welding, this surface appears to be the simplest and easiest to work with because of the flat position. The welding is performed from the upper surface and the molten floe is .

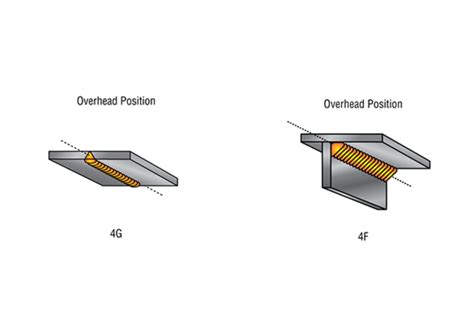

It is mainly used for very light gauge sheet metal welding. Most refineries and petrochemical plants do not allow the short circuiting mode of transfer in their welding specifications to weld on pressure retaining equipment. . weld is vertical, flat and overhead •6G- Pipe is inclined fixed at a 45 deg angle and not rotated during welding . To MIG weld overhead, first select the correct wire, gas, and settings. Position yourself comfortably and tilt the welding gun at a 45-degree angle. Use a . Overhead welding is a popular welding technique because it is one of the only ways to weld metal in place for larger objects such as buildings, pipelines, and more. However, overhead .

Changing the torch angle changes the percentage of heat that is transferred into the metal--ideal angle for the welding torch is 45º and distance between inner cone and metal is ideally 1/8" to ¼"--90° increase heating 0° reduces heating . thin sheet metal usually has enough reinforcement to give adequate strength, if reinforcement is .Conversely, if you make a bigger weld pool you will not achieve a good weld and molten filler metal and base metal will sag. Overhead Arc Welding Techniques! Stick Welding Weave Beads: The angle of your welding rod should be at ninety degrees to .

Study with Quizlet and memorize flashcards containing terms like A change in the number of sparks given off by the weld as it progresses can be used as an indication of ____. a) changes in the weld temperature b) changes in the temperature of the atmosphere c) changes in the torch angle d) changes in the flame size, Small amounts of total penetration usually will not cause a .

In this video I show how to set up your mig welder to be able to weld on super thin metal with out warping it. I go through step by step comparing how to pre.Study with Quizlet and memorize flashcards containing terms like Shirtsleeves should be rolled up when overhead welding., An electrode holder is held with knuckles facing upward and the palm facing downward., A 75° work angle is used when welding in overhead position. and more.I worked at a sheet metal manufacturer for years as a project manager and design engineer, the quoting process is quite simple. Laser time x laser rate +setup charges all divided by the qty ordered. . that probably means welding. Welding overhead is far more expensive (think roughly a dollar per inch) than bending up a piece of metal (~ per .

Sheet metal welding is a vital aspect of manufacturing. Read on to learn the different welding methods for the sheet metal parts. Capabilities. CNC Machining. CNC Milling; CNC Turning; Injection Molding. . To ease the difficulty of overhead welding, minimize the weld puddle. Also, ensure to use enough filler material to have a good weld. Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.You can use the pull technique in specific situations like when welding in tight spaces or when welding pieces in the overhead position. . Can you MIG weld sheet metal without gas? No, you cannot. Although some might argue that you can use Flux-Core wires for MIG welding thin gauge sheets, they have higher heat input which has risks of . On the other hand, if you are working with sheet metal, the welding can also be done downhill because you don’t need much penetration. To better understand overhead welding, compare it to bricklaying. Similar to bricklaying, the welder creates a weld slowly from the bottom and only works on a small section every time. The welder keeps working .

Workers who weld, braze and solder seams and joints may face hazards from overhead work. . Sheet Metal & HVAC. 2. Task. Weld, braze and solder seams and joints. 3. Hazard. Overhead work. 4. Hazard Analysis. 5. . Overhead work is a risk factor for musculoskeletal disorders (MSDs) such as tendonitis of the shoulder, and lifting can cause MSDs . Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process .Additionally, ensure the filler metal is always thinner than the sheet metal. Thinner fillers require less heat to melt, thus reducing the risk of overheating and its associated problems. 3. Choose a Small Wire Diameter. When welding sheet metal using the MIG welding process, you should always choose a small wire diameter.overhead Stick welding Skills by Brad...no problem . 💥overhead Stick welding Skills by Brad...no problem 😉💪👊👌👍 | Guernsey Sheet Metal 1993 Ltd Facebook

Overhead MIG Welding; Can You MIG Weld Aluminum Without Gas? Stick welders. Welding Rods Sizes; 7014 vs 7018 Welding Rods; 6011 vs 7018 Welding Rods . Each of the wires offers its own set of benefits and also possesses unique drawbacks. For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you . In summary, MIG welding is a widely used method of sheet metal welding that is relatively easy to learn and can be used to weld a variety of materials, such as mild steel, aluminum, and stainless steel. . while a faster speed is used for welding in the vertical and overhead positions. This is to ensure that the wire is fed at the appropriate .

Family owned, founded by Dan & Margie Bazella, Specialized Welding Inc. has been providing quality welding, machining, and fabricating to the greater Pittsburgh area for over 45 years. Some of our services include sheet metal fabrications, assembling and manufacturing. We specialize in welding of aluminum, stainless steel, titanium, nickel, carbon, inconel and low alloy steels. We . The filler metal is the material that melts into the weld and fills the gap between the two pieces being joined. MIG welding simplifies the feeding of filler metal, making the welder’s job easier. While the specific material may not be critical, the form of the filler metal is important when working with thin sheet metal. 3. Adjust the Torch .Here provides insights into sheet metal welding, covering processes, methods, and key factors for strong metal fabrication bonds. . Overhead Surface; Welding on an overhead surface is the most challenging due to the gravity pulling the molten metal downwards. It requires precise control to avoid excessive spatter and ensure a uniform weld. For sheet metal and plate, we have material yields between 75 and 90 percent, depending on the part shape, and around 80 to 92 percent for structural material, depending on the lengths and drop. . “For comparison, a welding process might have overhead costs for labor, consumables, supplies, and equipment of to an hour. .

Workers who weld, braze and solder seams and joints may face hazards from overhead work. . Sheet Metal & HVAC. 2. Task. Weld, braze and solder seams and joints. 3. Hazard. Overhead work. 4. Hazard Analysis. 5. . Overhead work is a risk factor for musculoskeletal disorders (MSDs) such as tendonitis of the shoulder, and lifting can cause MSDs .

welding overhead positions

According to Academia.Edu Trusted Source Mig Welding Research Papers - Academia.edu View Mig Welding Research Papers on Academia.edu for free. www.academia.edu , MIG welding has been in use for more than 25 years. If you’re just getting started with overhead MIG welding, you’re probably having a hard time perfecting your technique.

cnc manufacturer visalia ca

Vogel Sheetmetal, Inc in Stillwater, MN | Photos | Reviews | 172 building permits. Recent work: Furnish and install one (1) new vav and duct distribution to serve new space 182. duct insulation & test & balance. Contractor, Heating And Ventilation, Mechanical Contractor Bond, Plumbing License: BV003453, Mb003480, MB003480, PC003480.

overhead sheet metal weld|welding overhead cost