what does a cnc router machine do A CNC router is a computer-controlled cutting machine that uses a rotary tool to cut soft materials and metals. Learn more about it here. Here are some common types of welding joints: A butt joint refers to aligning the edges of two steel plates opposite each other and joining them tightly through welding processes to form a straight line on their surfaces.

0 · cnc router machines for beginners

1 · cnc router machine for woodworking

2 · cnc router definition

3 · cnc router cutting

4 · cnc machine for home hobbyist

5 · best cnc router for hobbyist

6 · best cnc machine for woodworking

7 · best cnc machine for beginner

Our product inventory includes various types of sheet metal fabrication tools and equipment. They are as described below. English Wheels: English wheels are the most popular metalworking tools in use today. These tools enable a user to create compound curves on a flat sheet of durable metal such as steel or aluminum.

cnc router machines for beginners

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can . A CNC router is a computer-controlled cutting machine that uses a rotary tool to cut soft materials and metals. Learn more about it here. A CNC router, directed by computer programs and codes, is a machine used for milling, drilling, engraving, and routing. A CNC router was primarily used to cut wood but has now expanded to carving and cutting .

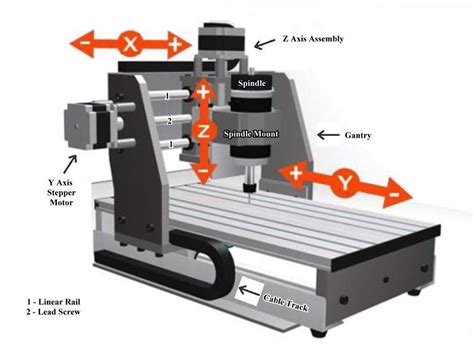

Key Takeaways. This article explains the fundamentals of CNC routers, including components and processes to help users achieve successful routing. The main components include a gantry assembly, Z-axis assembly, .

cnc router machine for woodworking

cnc router definition

How do CNC routers work and what can you make with a CNC router? Today's desktop CNC routers accurately cut parts to size and can do decorative carving. Throughout this ultimate guide, we have covered the basics of CNC routers and their various applications in CNC machining. We have discussed how to get started with CNC routers, including tips for building your . A CNC router is a computer-controlled machine that performs a wide range of functions in various industries, particularly woodworking. This article will delve into the different capabilities and applications of a CNC router to .

CNC routers are highly advanced machines capable of accurately transforming digital designs into complex parts. It utilizes computer programming to direct the tools along three-dimensional paths, creating cuts and shapes .

A CNC router is a computer-controlled cutting machine that is used for a wide range of applications, from woodworking and metalworking to plastic fabrication and signage. It operates on the Cartesian coordinate . A CNC router machine can be used for numerous applications, including: 2D and 3D carving, Woodworking, Acrylic fabrication, Aluminum fabrication, Cabinet making, Door making, Furniture making, Musical .Let’s have a look at using a CNC router to make wooden signs,mill brass,cut cardboardtemplates, machine polycarbonate and grave granite,and cut builders phone.Before getting started be sure to check the RPM of your spindle or router. In some cases the RPM is zero. You’ll also need to check the feed rate, the travel of the spindle, a router .

What a CNC router machine does. The main function of machine is to machine materials using a rotating cutter. A milling cutter is a cutting tool with sharp teeth that moves along a predetermined path, ensuring high precision .The CNC router we talk today is the wood CNC router, and often called wood CNC machine, CNC wood carving machine, CNC engraving machine, and wood router machine. It can process many materials, including hard and soft wood, MDF, particle board, acrylic, plastic, stone, soft metal etc.

wholesale cnc milling machine supplier

To the CNC router in Jinan (the mecca of CNC routers, fiber lasers, and other machines), there's a dark side, a positive side, and a big market waiting for CNC in the west. The avg ATC (Auto tool changer) machine cost between ⅓ to ⅕ Of similar machine in the west.

CNC routers can create intricate designs on a range of materials such as wood, plastic, and metal. Designs can be uploaded to the CNC router software, which then translates the design into code that the machine can execute. Some popular CNC router designs include: Geometric patterns; 3D carvings; Engravings; Custom signs and lettering . The bed is the foundation of a CNC router where the raw stock or material is mounted. It provides stability and support during the cutting process. CNC router beds may have holes or attachment points for clamping hardware to secure the material in place. 2. CNC Router Controller. The controller is the brain of the CNC router machine.Machine rigidity is a big concern, because a flimsy machine will deflect under load, causing poor tolerances and chatter - resulting in poor surface finish. Even if your machine were perfectly rigid, the cutting tool will not be - this is especially apparent in hobby CNC routers which usually use bits 1/4" diameter or smaller. CNC Routing Process: How Does CNC Router Machines Work? CNC routers can be made from all varieties of materials, from plywood to aluminum extrusion to bespoke cast components. The layout typically consists of a similar set of parts. Let’s take a brief look at the main components that make up a common CNC router. CNC Router Parts. Bed/Table

What Does a CNC Router Do? A CNC router is a computer-controlled cutting machine used for cutting various materials such as wood, plastics, and metals. It works by using a spinning cutting tool to cut and carve the material based on a pre-programmed design. The nesting CNC machine is multi-axis rotation, and the CNC router machine is one for six and one for eight. Although the simple nesting CNC machine and the CNC engraving machine are moving in a gantry, the nesting CNC machine with a high configuration also moves in the gantry and the platform also moves.

What is a CNC Router? CNC routers are one popular application for CNC machining platforms. As an advanced type of tooling method, CNC routers operate with CAM software programs, a visual programming tool used to create geometric code or simply, g-code, the CNC computer language that operates the CNC machines.A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling gaps in manual labor with automation, allowing industries to scale with consistency and quality. What Does A CNC Machinist Do? CNC (Computer Numerical Control) machining is a precision and efficient method of manufacturing in the modern day. . This article identifies the most common materials used for computer numerical controlled router machines and describes the appropriate materials for specific uses, while predicting the behaviors of .

What is stepover: Stepover is the distance your CNC machine moves your bit after each pass in the XY plane, measured as a percentage of the tool diameter.; How stepover affects surface finish: Smaller stepovers result in .

I bought a CNC router a few years ago and had 3 table saws, line boring machine, CNC beam saw and a slider. Through the years I have been eliminating equipment as we find more ways for the CNC to do the work. First to go was 2 table saws, then the line borer. The beam saw went this spring and the slider will stay, as it does come in handy if a .

It's no milling machine but a router can do it in a pinch, even with a cheap 24krpm 2.2kw spindle. Reply reply . The CNC router for wood and aluminum is the priority. So, I'm planning to use the space I have for a 4'x4' router. It will be my . I am getting ready to start the wiring of my DIY CNC Router and I am not sure what kind of wire I need to use/buy. Here is a list of my components. 1. Mesa - 7I76E STEP/IO Step & dir plus I/O daughtercard 2. SMPS 60V1200W switching power supply 60V20A DC power transformer AC220V / 110V to DC60V1500W Electric machine power supply 3.

The CNC router is a complex machine where every part plays a crucial role in achieving top performance, especially in precision and accuracy. Let’s look at three main parts: the spindle, frame, and software, and how they affect the machine’s abilities. . Even if a CNC router does not cut exactly 10 inches every time, it can still be . The Best CNC Routers for Woodworking. 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC MachineWhat does a CNC router machine do? Answer. Cutting and other shaping tasks may be performed with the help of a CNC Router, a computer-controlled equipment that employs a high-speed rotating cutter and a computer to achieve precise . A CNC, or Computer Numerical Control router, is an automated cutting tool that relies on a computer program to navigate the workpiece. The user puts their design specifications into the computer, then the CNC router executes the commands. Manual operation is available for 5-axis CNC routers, but it’s common for automated industrial cutting.

CNC routers are revolutionizing the way countless individuals and industries bring their works of art to life, optimizing efficiency far beyond what was once thought possible. But what exactly is a CNC router? To help you comprehend its inner workings, here's an overview of how these powerful machines operate. Definition CNC routers are state-of-the-art machinesStructure Upgrade: Masuter Pro is an All-Aluminum CNC router machine. The Z-axis uses Linear Rail instead of rods and T8 lead screw, this greatly improves the stability and accuracy. Upgraded Controller Box: Compact controller box desgin. The emergency stop button and home button are more easily and more convenient to access.

CNC machines are used in a wide range of industries, including aerospace, automotive, medical, and consumer products. CNC machines can be used to perform a variety of tasks, including cutting, drilling, milling, routing, and engraving. CNC machines are capable of producing complex shapes and intricate designs with high precision and accuracy. Besides your CNC machine itself, the next most important part of machining is the router bit. Different bits make different cuts and have different jobs, and if you’re new to machining, navigating bits can be confusing.

AnoleX 3030-Evo Pro CNC Router Kit with a spindle speed of 10000RPM and a working area of 11.3*11.81*2.87inch (287*300*73mm), this machine has perfect function and rigidity, making it an ideal choice for CNC hobbyists looking to explore the world of CNC routing.

cnc router cutting

Before you head off to get your materials, here are some of the different types of sheet metal and their advantages and disadvantages. Alloy steel, as the name implies, mixes various components to provide a customisable set of characteristics. Carbon steel serves as this material's primary element. Other components are included, such as:

what does a cnc router machine do|cnc router cutting