fused filament fabrication metal FFF for metallic parts can be divided into five steps: (1) raw material selection and feedstock mixture (including palletization), (2) filament production (extrusion), (3) production of AM components using the filament extrusion .

Putty pads are used in conjunction with metallic and nonmetallic electrical boxes under the following conditions: 1. Where the aggregate area of the boxes will exceed 100 sq. in. per 100 sq. ft. of wall.

0 · who invented fdm printing

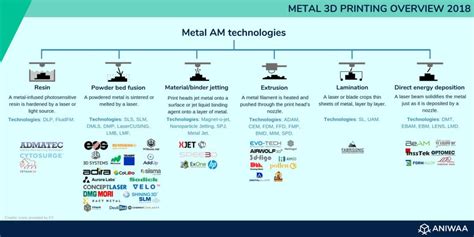

1 · types of metal 3d printing

2 · markforged metal 3d printing system

3 · markforged metal 3d printing

4 · fused filament fabrication 3d printing

5 · fused deposition modeling printer

6 · explain fused deposition modeling

7 · 3d printing fused deposition modeling

With a Japanese car, I doubt any of the sections on the car are 1.2mm. That is classic car thickness, not modern car metal. 1.0mm sheet will be plenty! ;-) 1.2mm is easier to weld with 0.6mm wire if you weld to the edge of the thicker material and let it run onto the thinner.

Metal fused filament fabrication (FFF) is the most accessible, easy to use, and affordable type of metal 3D printing technology. As a result, a range of industries — such as aerospace and automotive — have already tapped into metal FFF .FFF and the other technologies of additive manufacturing by material extrusion (EAM) techniques are commonly used for prototyping and rapid manufacturing. Rapid prototyping facilitates iterative testing, and for very short runs, rapid manufacturing can be a relatively inexpensive alternative. EAM is also used in prototyping scaffolds for medical tissue engineering applications. Moreover, E. Metal Fused Filament Fabrication (MFFF) uses powders from steel, ceramics, carbides, aluminum and copper. The powder particles must have a specific shape and size. . The very popular and economical material extrusion AM technique is fused filament fabrication (FFF). The article outlines the key concepts for FFF-based 3D printing of .

Fused filament fabrication (FFF) is one of the additive manufacturing (AM) techniques that have revolutionized the manufacturing strategy in the last 2 to 3 decades. The . FFF for metallic parts can be divided into five steps: (1) raw material selection and feedstock mixture (including palletization), (2) filament production (extrusion), (3) production of AM components using the filament extrusion .

What is fused filament fabrication and is it different from FDM? Learn what it is and how it was developed! FFFm is a quickly growing technology, relying on the extrusion of feedstocks consisting of metallic powder and a polymeric binder. The shaping step is identical to the wide . Additive manufacturing of metals using metal-fused filament fabrication (MF 3) is based on highly filled, metal powder-polymer filaments, where polymer binder helps to hold metal particles together in a feedstock and assist in material flow and deposition during extrusion-based printing [[1], [2], [3], [4]].As shown in Fig. 1, the printing process in metal-fused filament .Metal fused filament fabrication (metal FFF) is the most easy-to-use and affordable type of metal additive manufacturing technology.In a relatively simple three step process, metal FFF utilises bound metal powder and sintering – a .

Fused filament fabrication (FFF), otherwise known as fused deposition modeling (FDM) and a member of the material extrusion AM class, involves the directed deposition of a thermoplastic polymer filament in a layer-by-layer fashion. Shown in Fig. 4, a feeding system forces the spooled filament through a heating element in a process similar to a hot melt adhesive (hot glue) gun.In the metallic Fused Filament Fabrication (FFF) process, the material to be processed is stored on spools as filament (= wire) with a typical diameter of 1.75 mm or 2.85 mm. In this process, the filament consists of metal powder and a polymer mixture that melts at 150 °C - 200 °C. During the process, the filament is fed to a hot nozzle in . Metal-fused filament fabrication (MF3), which is a variation of the conventional fused filament fabrication (FFF), has recently gained interest due to its distinctive process flexibility and rapid prototyping capability to produce metallic parts. With respect to the additive manufacturing (AM) of aluminum alloys, most efforts have been centered on laser powder bed .Solutions for metal 3D printing with filament technology. Metal Fused Filament Fabrication is - to date - the simplest, and above all accessible technology to produce real metal parts. Its purpose is to create Full Metal functional parts, on which it is possible to carry out all surface finishing treatments, heat treatments and any post-processing for chip removal, such as grinding.

Fused Filament Fabrication (FFF) is an extrusion process where the object is built by depositing melted material layer-by-layer. The plastics used correspond to the same thermoplastics that can be found in conventional manufacturing processes, like ABS and Nylon .

who invented fdm printing

types of metal 3d printing

The article presents the main ideas for 3D printing of metal products based on the FFF technology. The technology utilizes layering of molten metal-containing filament. Metal Fused Filament Fabrication (MFFF) uses powders from steel, ceramics, carbides, aluminum and copper. The powder particles must have a specific shape and size.1 Introduction. Fused filament fabrication (FFF), also known as fused deposition modeling (FDM, which is the original trademark by Stratasys), is currently one of the most popular additive manufacturing (AM) techniques. [] According to the classification in ISO/ASTM 52900, [] FFF belongs to the “material extrusion” group, as the functioning mechanism of this technique .

In light of this, extrusion-based metal AM techniques, which utilize the fused filament fabrication (FFF) approach, are a great alternative to the current laser-based metal AM solutions.

Metal Fused Filament Fabrication (MF3) is an emerging additive manufacturing technology gaining popularity as a non-toxic and cost-effective alternative to other metal additive manufacturing methods. While offering applications in medical prosthetics, implants, automotive, aerospace, and sensors; challenges remain in achieving geometric . Fused filament fabrication (FFF) is an extrusion-based additive manufacturing (AM) technology mostly used to produce thermoplastic parts. However, producing metallic or ceramic parts by FFF is also a sintered-based AM process. FFF for metallic parts can . Fused filament fabrication (FFF) is one of the most popular additive manufacturing (AM) processes that utilize thermoplastic polymers to produce three-dimensional (3D) geometry products. The FFF filament materials have a significant role in determining the properties of the final part produced, such as mechanical properties, thermal conductivity, and electrical .

Fused Filament Fabrication (FFF) belongs to the Material Extrusion category and can be a cost-effective alternative for the fabrication of metal parts [5]. This process typically uses a thermoplastic polymer in form of filament that is fed into an extrusion system, heated above its glass transition temperature and then extruded and deposited in . One strategy is the development of novel processing methods which are outside conventional processing strategies. A contemporary example is additive manufacturing (AM), which, for thermoplastics, has enabled 3D printing of complex shapes through a material extrusion process, called fused filament fabrication (FFF). Fig. 8. SEM images of PLA-based scaffolds immersed in PBS for different immersion times. 4. Conclusions This work studied PLA/316L composite scaffolds with different metal contents fabricated by fused filament fabrication.

They are designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. BASF Forward AM Ultrafuse® Metal Filaments combine greater freedom of design with a lower total cost of ownership – printing metal . The exploitation of mechanical properties and customization possibilities of 3D printed metal parts usually come at the cost of complex and expensive equipment. To address this issue, hybrid metal/polymer composite filaments have been studied allowing the printing of metal parts by using the standard Fused Filament Fabrication (FFF) approach. The resulting .FFF (fused filament fabrication) FFF is the most commonly used 3D printing technology, due to its ease of use and lack of reliance on harsh chemicals. FFF uses a thick string of raw material, commonly referred to as filament. Filament is a constant width of either 1.75 mm or 2.85 mm, and is typically a thermoplastic that is delivered on a spool.

Fused filament fabrication (FFF) is a new procedure for the production of plastic parts, particularly if the parts have a complex geometry and are only needed in a limited quantity, e.g., in specific medical applications. In addition to the production of parts which are purely composed of polymers, fused filament fabrication can be successfully applied for the . Metal-fused filament fabrication (MF 3) is a hybrid additive manufacturing technique which essentially combines green part fabrication by fused-filament fabrication (FFF) and thermal processing of metal injection molding (MIM).As per ASTM terminology, the MF 3 process falls under material extrusion additive manufacturing (MEAM). MF 3 can offer several advantages . With fused filament fabrication (FFF), it is possible to produce large and complex components quickly with high material efficiency. In FFF, a continuous thermoplastic filament is melted in a heated nozzle and deposited below. The computer-controlled print head is moved in order to build up the desired shape layer by layer. To address this issue, hybrid metal/polymer composite filaments have been studied allowing the printing of metal parts by using the standard Fused Filament Fabrication (FFF) approach.

The application of additive manufacturing (AM) for tooling in the mould and die industry brings a disruptive potential in process performance, design flexibility and product enhancements. Maturing of existing AM technologies and emerging technologies such as metal-fused filament fabrication (metal FFF) can further support the applicability of AM tooling in .

Tosto C, Tirillò J, Sarasini F, Cicala G (2021) Hybrid metal/polymer filaments for fused filament fabrication (FFF) to print metal parts. Appl Sci 11:1. Article Google Scholar Rane K, Barriere T, Strano M (2020) Role of elongational viscosity of feedstock in extrusion-based additive manufacturing of powder-binder mixtures. A strategy that is gaining momentum in several industrial sectors is metal replacement, which aims to find suitable alternatives for replacing metal components with lighter ones. . In this research, an investigation was carried out on the Fused Filament Fabrication (FFF) of different 3D printed PEEK samples, evaluating the effect on final . Fused filament fabrication (FFF), a much-appreciated three-dimensional printing (3DP) technology, has triggered the industrial innovations by providing viable and cost-effective solutions for design validations, product prototyping, and the production of high-performance functional components. . PLA, LayWood, Metal Composite, Conductive .

markforged metal 3d printing system

metal meets house

Distribution boards are crucial in keeping power flowing smoothly in all these places. A distribution box is a smaller, protective unit in electrical systems. It houses electrical connections and helps distribute power safely. Think of it .

fused filament fabrication metal|types of metal 3d printing