cnc lathe machine calibration Steps to Calibrate a CNC Machine 1. Check Machine Geometry. The first step in calibrating a CNC machine is to check its geometry. This involves measuring the distance between various points on the machine, such as the . Open the electrical box panel so you can access the circuit breakers. Starting from left to right, flip each circuit breaker switch to the "Off" position. This will temporarily isolate all the electricity in your home. Listen to ascertain if you can hear a buzzing noise.

0 · mastering cnc calibration

1 · cnc calibration tools

2 · cnc calibration process

3 · calibration for cnc machine

5. Is a metal roof more expensive than an asphalt shingle roof? A metal roof is almost always more expensive than shingles. However, it heavily depends on the metal type .

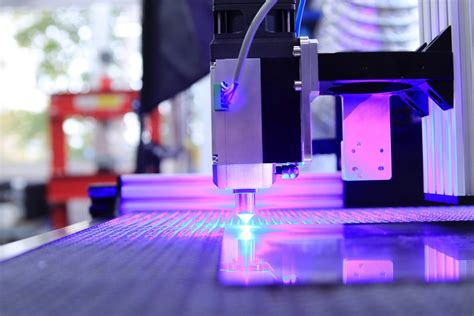

CNC Lathe machines are highly accurate and precise, allowing them to produce high-quality parts with tight tolerances. However, in order to maintain this level of accuracy, it is important to .Welcome to our comprehensive guide on CNC lathe setup and calibration. In this .Calibration, done right, follows meticulous step-by-step procedures and employs a variety of exclusive techniques such as machine warming, params checking, and backlash analysis, . Steps to Calibrate a CNC Machine 1. Check Machine Geometry. The first step in calibrating a CNC machine is to check its geometry. This involves measuring the distance between various points on the machine, such as the .

Calibration is the process of aligning and adjusting various components of the CNC machine to ensure consistent and accurate results. It plays a vital role in achieving the desired precision, .

Welcome to our comprehensive guide on CNC lathe setup and calibration. In this blog post, we will delve into the intricacies of setting up and calibrating a CNC lathe machine, providing you .

To achieve precise calibration of CNC machines, several essential tools are required. A QC20 ballbar is a precision measuring device that detects minute variations in radius by following a programmed circular path around a .

Calibration of CNC floor-type lathes is essential for maintaining precision and ensuring the machine operates within its specified tolerances. A systematic calibration process . Machine tool calibration encapsulates a series of meticulous procedures aimed at ensuring the accuracy and reliability of machining operations. From CNC machines to lathes and grinders, each tool undergoes .

Calibration and tuning your CNC machine will help you achieve consistent and reliable results. There are three primary procedures we recommend after initial machine assembly (and before creating the spoilboard). Step 1: Open the MDI window using the MDI button in F2 Screen or CTRL+M and load the tool you would like to calibrate, in this example we will be calibrating Tool No.1. Step 2: Machine a small test piece or use an existing piece.

CNC Lathe machines are highly accurate and precise, allowing them to produce high-quality parts with tight tolerances. However, in order to maintain this level of accuracy, it is important to calibrate the machine regularly.

Calibration, done right, follows meticulous step-by-step procedures and employs a variety of exclusive techniques such as machine warming, params checking, and backlash analysis, alongside the use of precision calibration instruments. Steps to Calibrate a CNC Machine 1. Check Machine Geometry. The first step in calibrating a CNC machine is to check its geometry. This involves measuring the distance between various points on the machine, such as the spindle centerline and the worktable, to ensure that they are within tolerance.Calibration is the process of aligning and adjusting various components of the CNC machine to ensure consistent and accurate results. It plays a vital role in achieving the desired precision, reducing errors, and optimizing the machine's performance.

Welcome to our comprehensive guide on CNC lathe setup and calibration. In this blog post, we will delve into the intricacies of setting up and calibrating a CNC lathe machine, providing you with detailed instructions and insightful tips. To achieve precise calibration of CNC machines, several essential tools are required. A QC20 ballbar is a precision measuring device that detects minute variations in radius by following a programmed circular path around a fixed mount. Calibration of CNC floor-type lathes is essential for maintaining precision and ensuring the machine operates within its specified tolerances. A systematic calibration process helps achieve optimal performance, reduce waste, and extend the machine’s lifespan.

Machine tool calibration encapsulates a series of meticulous procedures aimed at ensuring the accuracy and reliability of machining operations. From CNC machines to lathes and grinders, each tool undergoes a rigorous calibration process to uphold stringent quality standards.Calibration and tuning your CNC machine will help you achieve consistent and reliable results. There are three primary procedures we recommend after initial machine assembly (and before creating the spoilboard). Step 1: Open the MDI window using the MDI button in F2 Screen or CTRL+M and load the tool you would like to calibrate, in this example we will be calibrating Tool No.1. Step 2: Machine a small test piece or use an existing piece.CNC Lathe machines are highly accurate and precise, allowing them to produce high-quality parts with tight tolerances. However, in order to maintain this level of accuracy, it is important to calibrate the machine regularly.

Calibration, done right, follows meticulous step-by-step procedures and employs a variety of exclusive techniques such as machine warming, params checking, and backlash analysis, alongside the use of precision calibration instruments. Steps to Calibrate a CNC Machine 1. Check Machine Geometry. The first step in calibrating a CNC machine is to check its geometry. This involves measuring the distance between various points on the machine, such as the spindle centerline and the worktable, to ensure that they are within tolerance.Calibration is the process of aligning and adjusting various components of the CNC machine to ensure consistent and accurate results. It plays a vital role in achieving the desired precision, reducing errors, and optimizing the machine's performance.Welcome to our comprehensive guide on CNC lathe setup and calibration. In this blog post, we will delve into the intricacies of setting up and calibrating a CNC lathe machine, providing you with detailed instructions and insightful tips.

To achieve precise calibration of CNC machines, several essential tools are required. A QC20 ballbar is a precision measuring device that detects minute variations in radius by following a programmed circular path around a fixed mount. Calibration of CNC floor-type lathes is essential for maintaining precision and ensuring the machine operates within its specified tolerances. A systematic calibration process helps achieve optimal performance, reduce waste, and extend the machine’s lifespan.

Machine tool calibration encapsulates a series of meticulous procedures aimed at ensuring the accuracy and reliability of machining operations. From CNC machines to lathes and grinders, each tool undergoes a rigorous calibration process to uphold stringent quality standards.

Calibration and tuning your CNC machine will help you achieve consistent and reliable results. There are three primary procedures we recommend after initial machine assembly (and before creating the spoilboard).

stainless steel bread box canada

BR Metal is the #1 custom metal fabrication company in Wisconsin. Get custom CNC machining, welding, powder coating, and more. Shop our POS & LCD mounts online.

cnc lathe machine calibration|mastering cnc calibration