cnc lathe machine sketch A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. These lathes contain different equipment, including a spindle, a chuck to hold the object, a motor to . $499.99

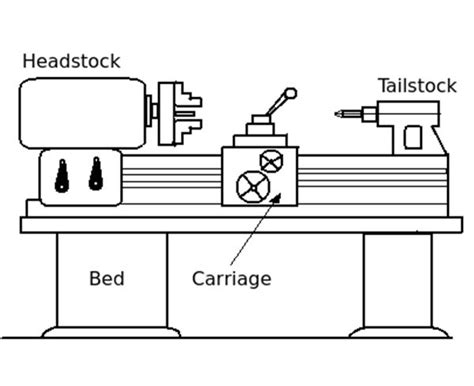

0 · sketch of a lathe machine

1 · simple diagram of lathe machine

2 · lathe machine specification with diagram

3 · lathe machine schematic diagram

4 · lathe machine drawing with parts

5 · labelled diagram of lathe machine

6 · easy drawing of lathe machine

7 · easy diagram of lathe machine

If the smoke detectors were installed properly, there should be a junction box behind them. If so, capping each of wires with appropriately sized wire nuts and leaving them in the junction box .

This is my cnc lathe machine project that I am working on. This lathe machine have some cool feature like atc 8 station live tooling. 1.5 kw ac servo spindle. Everything is made from sketch.In addition to an accurate and clear detail drawing, you must also complete a setup sheet for the machine you plan to use to manufacture your part: CNC Lathe Setup Sheet The setup sheet .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or . A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. These lathes contain different equipment, including a spindle, a chuck to hold the object, a motor to . Technical CNC drawings for CNC machining is a detailed, precise, and scaled representations of a part or component that will be manufactured using CNC machines. It includes information such as dimensions, tolerances, .

What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, .

In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques .

This is my cnc lathe machine project that I am working on. This lathe machine have some cool feature like atc 8 station live tooling. 1.5 kw ac servo spindle. Everything is made from sketch.In addition to an accurate and clear detail drawing, you must also complete a setup sheet for the machine you plan to use to manufacture your part: CNC Lathe Setup Sheet The setup sheet includes details of each tool used in the manufacturing, as well as sketches and notes explaining where your part datums/zeros are located for each operation.The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. A CNC lathe is a fully automated machine capable of precise turning and drilling operations. It follows G-code programming intended for subtractive manufacture (cutting) and starts with either a suitable material blank or a preform.

While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components.

A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. These lathes contain different equipment, including a spindle, a chuck to hold the object, a motor to rotate the object, and servo motors to shift the cutting tool to the machining area. Technical CNC drawings for CNC machining is a detailed, precise, and scaled representations of a part or component that will be manufactured using CNC machines. It includes information such as dimensions, tolerances, material specifications, and any other relevant details needed to accurately produce the part.

What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes. In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.

This is my cnc lathe machine project that I am working on. This lathe machine have some cool feature like atc 8 station live tooling. 1.5 kw ac servo spindle. Everything is made from sketch.In addition to an accurate and clear detail drawing, you must also complete a setup sheet for the machine you plan to use to manufacture your part: CNC Lathe Setup Sheet The setup sheet includes details of each tool used in the manufacturing, as well as sketches and notes explaining where your part datums/zeros are located for each operation.

sketch of a lathe machine

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. A CNC lathe is a fully automated machine capable of precise turning and drilling operations. It follows G-code programming intended for subtractive manufacture (cutting) and starts with either a suitable material blank or a preform.While CNC machines can be found in different configurations, the most common ones are CNC mills and CNC lathes. CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components.

A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. These lathes contain different equipment, including a spindle, a chuck to hold the object, a motor to rotate the object, and servo motors to shift the cutting tool to the machining area. Technical CNC drawings for CNC machining is a detailed, precise, and scaled representations of a part or component that will be manufactured using CNC machines. It includes information such as dimensions, tolerances, material specifications, and any other relevant details needed to accurately produce the part.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

how to choose a cnc machine

how to calculate sheet metal flat pattern

In this guide, we'll explore the pros and cons of unfinished cabinets, how to add finish to your unfinished cabinets, types of cabinet finishes, and ideas to make them beautifully complement your ideal aesthetic.

cnc lathe machine sketch|simple diagram of lathe machine