deep drawing metal power box Whether you require deep draw hydroforming, custom aluminum instrument enclosures, sheet metal enclosure fabrication, aluminum electronic project box, or custom stainless enclosures, we will work with you to create a solution that . What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and .

0 · metalforming drawing depth

1 · deep metal drawing

2 · deep drawn metal enclosures

3 · deep drawn metal enclosure catalog

4 · deep drawing of sheet metal

5 · deep drawing metal parts

6 · deep drawing metal forming

7 · deep drawing die

What is an Electrical Pull Box? An electrical pull box, also known as a junction box, is a container that is used to house electrical connections and provide a safe and accessible location for splicing wires.

Hudson Technologies manufactures deep drawn metal battery enclosures for a wide range of industries and applications across the globe —including . Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. However, when broken down into simple components, such as .We have over 25,000+ standard shapes and sizes of deep drawn metal enclosures available with little to no tooling costs. We can also engineer your customized tooling for any standard metal .

cnc machining tucson salary

Whether you require deep draw hydroforming, custom aluminum instrument enclosures, sheet metal enclosure fabrication, aluminum electronic project box, or custom stainless enclosures, we will work with you to create a solution that .Amalco is a leading manufacturer of deep drawn and hydroformed metal parts for the aerospace, communications, industrial, lighting, medical, military, and nuclear sectors. Our expert machinists prepare every part in advance of the forming .Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal .Hudson Technologies manufactures deep drawn metal battery enclosures for a wide range of industries and applications across the globe —including implantable medical devices, aerospace, aviation, oil exploration, military, energy storage, and hybrid electric vehicles, to name just a few.

Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation to understand and troubleshoot.

We have over 25,000+ standard shapes and sizes of deep drawn metal enclosures available with little to no tooling costs. We can also engineer your customized tooling for any standard metal enclosure to your specific specifications. Enhance your metal stamping and die design skills with our comprehensive guide on deep drawing. Learn the process, techniques, and tips for successful metal forming.Whether you require deep draw hydroforming, custom aluminum instrument enclosures, sheet metal enclosure fabrication, aluminum electronic project box, or custom stainless enclosures, we will work with you to create a solution that meets your specific needs.

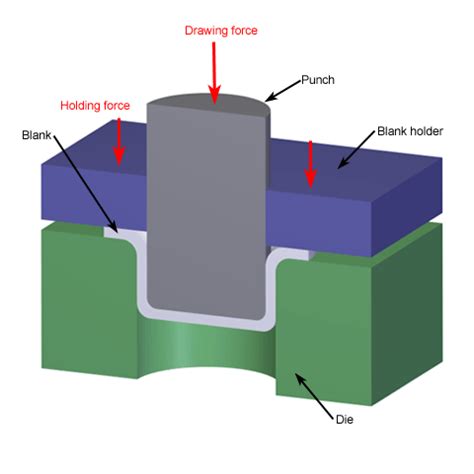

Amalco is a leading manufacturer of deep drawn and hydroformed metal parts for the aerospace, communications, industrial, lighting, medical, military, and nuclear sectors. Our expert machinists prepare every part in advance of the forming process to ensure that the results are free from tears, cracks, voids and imperfections.Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal blank over a cavity.Master deep drawing stainless steel with our guide. Explore techniques, applications, and industry insights for superior metal forming. Deep drawing transforms flat stainless steel sheets into three-dimensional shapes without welding or joining.With our extensive deep-drawing capabilities, National can produce deep drawn cases, deep drawn enclosures and deep drawn metal stampings in a wide variety of metals to exacting tolerances, in various configurations, complex shapes and sizes.

A metal enclosure that is deep drawn is a type of enclosure that is formed by drawing a flat sheet of metal into a three-dimensional shape using a stamping press. The process involves placing a sheet of metal over a die and then using a punch to force the .

Hudson Technologies manufactures deep drawn metal battery enclosures for a wide range of industries and applications across the globe —including implantable medical devices, aerospace, aviation, oil exploration, military, energy storage, and hybrid electric vehicles, to name just a few. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. However, when broken down into simple components, such as boxes and cups, deep drawing becomes a much simpler operation to understand and troubleshoot.We have over 25,000+ standard shapes and sizes of deep drawn metal enclosures available with little to no tooling costs. We can also engineer your customized tooling for any standard metal enclosure to your specific specifications.

Enhance your metal stamping and die design skills with our comprehensive guide on deep drawing. Learn the process, techniques, and tips for successful metal forming.

Whether you require deep draw hydroforming, custom aluminum instrument enclosures, sheet metal enclosure fabrication, aluminum electronic project box, or custom stainless enclosures, we will work with you to create a solution that meets your specific needs.Amalco is a leading manufacturer of deep drawn and hydroformed metal parts for the aerospace, communications, industrial, lighting, medical, military, and nuclear sectors. Our expert machinists prepare every part in advance of the forming process to ensure that the results are free from tears, cracks, voids and imperfections.

Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal blank over a cavity.Master deep drawing stainless steel with our guide. Explore techniques, applications, and industry insights for superior metal forming. Deep drawing transforms flat stainless steel sheets into three-dimensional shapes without welding or joining.With our extensive deep-drawing capabilities, National can produce deep drawn cases, deep drawn enclosures and deep drawn metal stampings in a wide variety of metals to exacting tolerances, in various configurations, complex shapes and sizes.

cnc machining wood handle manufacturers

metalforming drawing depth

cnc machining topics

deep metal drawing

deep drawn metal enclosures

Owner/electrical contractor Feb 15, 2020 . Still wouldn’t make it compliant. (Picture of a 1900 box)

deep drawing metal power box|metalforming drawing depth