cnc machine fixtures Fixtures, through their design and types, underpin CNC machining's efficiency and accuracy. From positioning workpieces to maintaining consistency, they are integral to smooth operations. To explore further, visit . Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes.

0 · workholding fixtures for machining

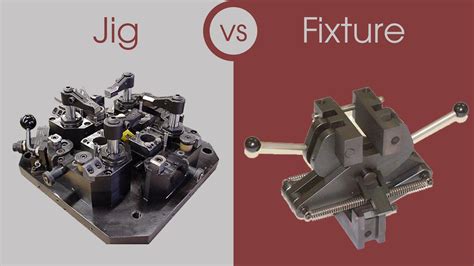

1 · types of fixtures and jigs

2 · tapped table fixture cnc machine

3 · list of jigs and fixtures

4 · jigs and fixtures for cnc

5 · holding fixtures for cnc machines

6 · fixture plates for cnc mills

7 · fixture plate for milling machine

Learn about a junction box as it pertains to a residential home and its electrical wiring, plus DIY tips to install an electrical junction box.

CNC fixtures are essential tools that play significant roles in CNC machining, allowing quicker operation and production of precise parts according to design specifications. The appropriate use of a CNC fixture guarantees . Fixtures, through their design and types, underpin CNC machining's efficiency and accuracy. From positioning workpieces to maintaining consistency, they are integral to smooth operations. To explore further, visit . CNC fixtures are essential in modern machining operations enhancing production efficiency and machining precision. Furthermore, using CNC fixtures allows you to churn out multiple identical parts to high accuracy .

Discover CNC jigs, fixtures and workholding solutions for milling machines. Get tips and ideas to optimize your machining process at CNCCookbook.

This comprehensive guide explores CNC fixtures, offering insights into their definition, types, mechanism and role in manufacturing processes. Computer Numerical Control (CNC) fixtures are crucial tools in the . A CNC fixture is a custom workholding device that securely holds a workpiece in place on a computer numerical control (CNC) machining center. It allows the machine tool to accurately locate and secure the workpiece for .This article will cover a detailed guide on a CNC fixture and its types so you can choose the ideal one before proceeding with CNC machining.

In this article, we’ll explore how choosing the right CNC fixtures can revolutionize small batch production, saving time and boosting efficiency. Get ready to learn practical tips that can transform your machining process! . CNC fixtures are essential tools that play significant roles in CNC machining, allowing quicker operation and production of precise parts according to design specifications. The appropriate use of a CNC fixture guarantees coherence and interchangeability in . In this guide, we will provide an overview of CNC fixture design and offer tips on how to create effective fixtures for your machining projects. We’ll discuss the different types of fixtures and their uses, as well as best practices for designing and testing your fixtures. Fixtures, through their design and types, underpin CNC machining's efficiency and accuracy. From positioning workpieces to maintaining consistency, they are integral to smooth operations. To explore further, visit CNCYANGSEN for a closer look at these remarkable tools that boost productivity in machining.

The ten most common fixtures range from CNC vises to self-fixturing and vacuum workholding. John Saunders of NYC CNC created a video series that breaks down the top 10 CNC fixturing types, from soft jaws to custom fixtures.

workholding fixtures for machining

CNC fixtures are essential in modern machining operations enhancing production efficiency and machining precision. Furthermore, using CNC fixtures allows you to churn out multiple identical parts to high accuracy useful in mass production. Discover CNC jigs, fixtures and workholding solutions for milling machines. Get tips and ideas to optimize your machining process at CNCCookbook.

gkd metal fabrics kiwi

This comprehensive guide explores CNC fixtures, offering insights into their definition, types, mechanism and role in manufacturing processes. Computer Numerical Control (CNC) fixtures are crucial tools in the manufacturing industry, providing support and precision for machining operations. A CNC fixture is a custom workholding device that securely holds a workpiece in place on a computer numerical control (CNC) machining center. It allows the machine tool to accurately locate and secure the workpiece for machining operations like .This article will cover a detailed guide on a CNC fixture and its types so you can choose the ideal one before proceeding with CNC machining.

In this article, we’ll explore how choosing the right CNC fixtures can revolutionize small batch production, saving time and boosting efficiency. Get ready to learn practical tips that can transform your machining process! Currently, machining operations can be broadly classified into two categories based on production volume: CNC fixtures are essential tools that play significant roles in CNC machining, allowing quicker operation and production of precise parts according to design specifications. The appropriate use of a CNC fixture guarantees coherence and interchangeability in . In this guide, we will provide an overview of CNC fixture design and offer tips on how to create effective fixtures for your machining projects. We’ll discuss the different types of fixtures and their uses, as well as best practices for designing and testing your fixtures.

types of fixtures and jigs

Fixtures, through their design and types, underpin CNC machining's efficiency and accuracy. From positioning workpieces to maintaining consistency, they are integral to smooth operations. To explore further, visit CNCYANGSEN for a closer look at these remarkable tools that boost productivity in machining. The ten most common fixtures range from CNC vises to self-fixturing and vacuum workholding. John Saunders of NYC CNC created a video series that breaks down the top 10 CNC fixturing types, from soft jaws to custom fixtures.

CNC fixtures are essential in modern machining operations enhancing production efficiency and machining precision. Furthermore, using CNC fixtures allows you to churn out multiple identical parts to high accuracy useful in mass production. Discover CNC jigs, fixtures and workholding solutions for milling machines. Get tips and ideas to optimize your machining process at CNCCookbook.

This comprehensive guide explores CNC fixtures, offering insights into their definition, types, mechanism and role in manufacturing processes. Computer Numerical Control (CNC) fixtures are crucial tools in the manufacturing industry, providing support and precision for machining operations.

A CNC fixture is a custom workholding device that securely holds a workpiece in place on a computer numerical control (CNC) machining center. It allows the machine tool to accurately locate and secure the workpiece for machining operations like .This article will cover a detailed guide on a CNC fixture and its types so you can choose the ideal one before proceeding with CNC machining.

tapped table fixture cnc machine

gioconda art set in metal box 8890

gioconda art set in metal box 8890

Electrical gang boxes, also known as electrical junction boxes, are containers used to house electrical connections and protect them from external elements. These boxes are typically made of metal or plastic and come in various shapes and sizes to accommodate different electrical installations.

cnc machine fixtures|fixture plates for cnc mills