sheet metal bending formula k factor K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the . You will have to use a ground screw or pigtail to tie the box and ground wires all together. You may or may not need to have a ground wire attach to the receptacle, depending .

0 · k factor sheet metal chart

1 · k factor sheet metal calculator

2 · k factor for stainless steel

3 · k factor for 5052 aluminum

4 · k factor calculator excel

5 · how to calculate k factor

6 · bend allowance k factor chart

7 · 304 stainless steel k factor

Need a connector or lead for your TV setup? We explain what the connectors do, and aim to point you in the right direction. An Aerial Flylead is used to connect from a TV aerial socket on the wall to an aerial input socket on a TV or set-top box. They are also used to connect set-top boxes and recorders to TV sets.

what mens cologne comes in yellow metal box

k factor sheet metal chart

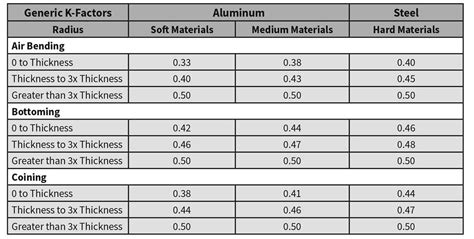

We calculate k-factor by dividing t by the material thickness (Mt): k-factor = t/Mt, The k-factor is nothing more than a multiplier that can give you an accurate value for the . K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the .Use our K-factor calculator to determine the position of the neutral axis in the sheet of metal you are planning to bend.

k factor sheet metal calculator

The K-Factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. It’s used to determine Bend Allowances and Bend Deductions ahead of the first piece.

How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and . Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the .

We've created a comprehensive guide to explain the K factor, its formula, and its implications. Simply input your material thickness, initial length, and inner radius into our calculator, and . The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending .

To calculate the k-factor, you need to collect some information: specifically, the BA and the Ir. Measure each test piece, determine the average, then insert that value into the k-factor formula, which I’ll get to later.How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°. The k-factor allows you to calculate the bend allowance, the outside setback, the bend deduction, and the flat layout of the precision part you’re forming. The neutral axis does not suffer any change [of] length during . This K-factor is applied as an average value for most bend allowance calculations. There are other values for stainless and aluminum, but in most cases, 0.446 in. works across most material types. . More Than One .

5 Important Sheet Metal Design Formulas #1 K-Factor. The K-Factor is a crucial parameter used to determine how much a given material will stretch or compress during bending. The K-Factor is used to calculate the Bend Deduction and Bend Allowance (formulas #2 and #3), which in turn are used to determine the correct size of the unfolded flat . To enhance the readers’ understanding of basic concepts in sheet metal design calculation, the following points will be summarized and explained:. The definitions of the two bending algorithms: bend allowance and bend deduction, and their connection to the actual sheet metal geometry. The relationship between bend deduction and bend allowance, and how .Bend Allowance (mm): Material Thickness (mm): Bend Angle (degrees): K Factor: Calculate The K Factor in sheet metal bending is a crucial parameter that helps in determining the correct bend allowance and bend deductions for creating accurate sheet metal parts. It is essential for ensuring that the final dimensions of the bent parts match the . Bend Calculation option in the dialog. The dropdown options are: K Factor: A dimensionless factor representing the ratio of the neutral axis length to the material thickness during bending. It is a common choice for many sheet metal .

k factor for stainless steel

k factor for 5052 aluminum

what size are electrical box screws

what parts should be used in a cnc mill

If you look at a receptacle from the back, you'll typically see that the attachments to the box are part of the same metal band that the ground screw is attached to. That, too, can rust. A copper wire under the brass screw is a better ground.

sheet metal bending formula k factor|k factor sheet metal chart