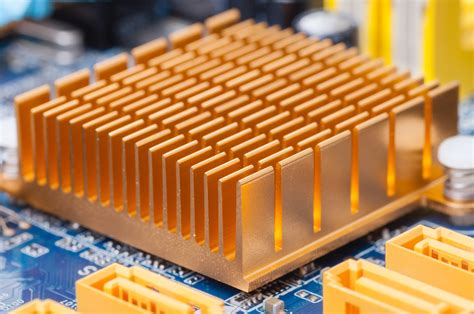

sheet metal heat sink A heat sink is a part that conducts heat from a heat generating component to a larger surface area to dissipate the heat to the surroundings thus reducing the temperature of the component. Based on this definition anything from a . Percy Martin is a family owned & managed business, and will soon be celebrating 100 years of continuous trading. Since being founded in 1921 by Percy Martin, it has passed through 4 generations of the Martin family to become one of the UK’s .

0 · what is a heat sink computer

1 · types of heat sinks

2 · how do heat sinks work

3 · heat sink thermal resistance

4 · heat sink meaning in computer

5 · best heat sink material

6 · aluminum heat sink material

7 · active liquid heat sink

The main spindle has a 15 kW power with speeds up to 4500 rpm, and the counter-spindle offers 11 kW power with speeds up to 5000 rpm. The machine has a large .

We’ve utilized this experience and knowledge to develop our Heat Sink Reference Guide to help you find the right heat sink solution. This article covers the most popular passive heat sink .These heat sinks are formed through progressive punching processes, where .Choosing the correct heat sink is essential to optimized cooling, with higher .These heat sinks are formed through progressive punching processes, where details and features are progressively added with each stamp of sheet metal going through the punching die. Stamped Heat Sinks are designed for specific .

A heat sink is a part that conducts heat from a heat generating component to a larger surface area to dissipate the heat to the surroundings thus reducing the temperature of the component. Based on this definition anything from a .Choosing the correct heat sink is essential to optimized cooling, with higher performance in more compact geometries at the correct price point. Our quick reference guide will help you to decide where to begin in building and .

A custom heatsink is designed to your device’s specifications, ensuring optimal thermal management. By considering factors such as the device’s power dissipation, airflow, and .

Heat sinks are crucial in dissipating excess heat from electronic devices, preventing them from overheating and ensuring optimal performance. Various heat sink types have emerged with .There are three main modes of heat transfer that heat sinks can use: conduction, convection, and radiation. Conduction is the direct transfer of heat through physical contact. Convection is the transfer of heat by the movement of fluids, . A heat sink is a mechanical component used in electronic devices to prevent overheating electrical components by providing supplementary cooling. It dissipates heat from an electrical component, usually a power transistor, to . Zipper fins heat sinks are a great heat transfer solution. While Genie uses them in the simplest form, zipper fins have a wide range of application and design flexibility. Contact Boyd Design Engineers for assistance with your .

The heat source is assumed to cover the entire base of the heat sink. The heat sink size calculator first calculates the optimum spacing between the fins to achieve maximum convection cooling. The width of the heat sink is then .Stamped heat sinks are made with sheet metal that has gone through a progressive punching process where details and features are added with each stamp of metal going through the punching die. Stamped heat sink geometries . In the thermal management world, folding metal sheets enables us to increase the amount of surface area within a given volume. Surface area is crucial for effective heat transfer. Folding fins from a single piece also .Heat Sinks, Power Supply Cabinet & Laser Cutting Services Manufacturer offered by Parmar Engineering Works from Mumbai, Maharashtra, India . Supplier, Service Provider and Exporter in providing qualitative range of Heat Sinks, Sheet Metal Fabrication, Sheet Metal Components, Laser Labour Job and many more. Read more. Nature of Business .

Sheet Metal Heat Sink product price in India ranges from 100 to 5,000 INR and minimum order requirements from 1 to 10,000. Whether you're looking for HSM Multispan Heat Sink, GSCSLX55 Thermo-Conductive Plate and Reservoir Modules Cool Sink, To-220 Heat Sink (Black) etc, you can explore and find the best products from Tradeindia. We offer a wide .

Sheet Metal Parts, Din Rail Channel, MCB Channel, Handles for Valve, Mounting Brackets, Stamped Parts, Laser Cut Sheet Metal Parts, Priyank Engineering, Ahmedabad Aluminium Heat Sink Manufacturer in Ahmedabad, India Brazed fin heat sinks have the added bonus of a stronger joint with less interface resistance between the base and fins. Pick your Process: The Different Types of Brazing. . Robust Sheet Metal Fabrication to Optimize Performance At Boyd, we leverage our expertise in sheet metal manufacturing. Zipper fins are sheets of metal that are progressively punched out of stock material. First the geometry of the fin is created with the punches. . Zipper fin heat sinks are ideal for high volume applications as opposed to low quantity production runs since the cost of the punches will be spread out across fewer heat sinks.Parmar Engineering Works | Sheet Metal Works And Heat Sinks - Manufacturer of Heat Sinks, Power Supply Cabinet and Laser Cutting Services from Mumbai. Parmar Engineering Works. Sakinaka, Mumbai, Maharashtra GST No. 27AAWFP4725B1Z1. Call 08048960148 68% Response Rate. Send Email. Home;

Extruded heat sink. Water-cooling plate. Stamped sheet metal. Heat pipe heat sink. Welded water-cooled plate. Glued heat sink. Riveted heat sink. Shovel tooth heat sink. Forged products. Die casting. Machined products. Electronic standard heat sink. Customization. Optimization of heat dissipation design. Sample development. Equipment. Equipment .The free flat plate heat sink calculator is a tool for calculating the perfomance a heat sink formed from a flat sheet of metal cool via natural convection and radiation. Home; Blog; About; FAQ; Login Login Sign . The heat sink thermal resistance and temperature of the heat source are calculated by the calculator. Dimensions. Air Flow. Power .Hot Dam Heat Stop Compound completely stops heat transfer down ferrous or non-ferrous pipe. It easily molds like clay to any shape and can be used over and over and removes quickly and cleanly after each application. No drip, mess or residue. Ideal for apCNC Machining Heat Sinks find applications in cooling electronic control units (ECUs), battery management systems, and advanced driver-assistance systems (ADAS). . we offering 5 and 3 axis,Laser Cutter,3D Printer,Sheet Metal Machine,Casting Machie,EDM,Injection Molding Machine,Forging Machine,Stamping Machine capability, see prototype .

Welders can struggle with thin sheet metal because the hot arc warps or burns through the metal easily. Even professional welders flounder with welding thin . Additionally, the heat retention in the HAZ encourages warping and burn-through. Using heat sinks is less effective with stainless steel than mild steel. Unlike steel, aluminum conducts . Lets design sheet metal Kitchen Sink in Creo Parametric.Insert flat pattern in the sheet metal drawing in Creo Parametric.https://youtu.be/GN8Uq_n72WUThe bas.

Stamped heat sinks are manufactured by stamping flat metal sheets into desired shapes, typically using a press. This cost-effective method is suitable for producing large quantities of heat sinks quickly. Pros: Cost-effective for large volumes: Stamping is .

If it's only a couple, then just bolt them flat to the board and leave a square inch of bare copper in case you need to add a stamped sheet metal heat sink under the part. If it's more like 10 Watts, then you want a vertical finned unit.

Related: Heat Sink Design Process: Materials, Manufacturing, and Design Considerations. . Case Studies: Successful Application of Embossed Heat Shields. Sheet metal embossing has proven to be an effective technique in various industries, especially in automotive manufacturing. One of its significant applications is in the production of heat .

CNC Machined Heat Sinks . . Heatsink material; aluminum, copper, or another sheet metal (copper metal heatsink) Step 2: Cutting out the Heatsink . Use the nibbler to cut shapes from your piece of aluminum. Then, ensure the heatsink has a large surface area to absorb excess heat. While it can be any shape, note that the tab should be taller .A novel method and apparatus utilizing sheet metal fabricated to form highly effective heat sinks having a low cost is disclosed. Fabrication techniques including punching and bending are used to create one or more tubes having substantially rectangular cross-sections. The rectangular-section tubes share a common base. In a particular illustrative example of the invention, a plurality of .

Supplier and Manufacturer of Sheet Metal Components and Heat Sinks offered by Sidh Engineers, Ghaziabad, Uttar Pradesh, India. Sheet Metal Components & Heat Sink. We provided best quality Heat Sink and Sheet Metal Components which reflects high durability and export quality. They can be sued in various engineering and other allied industries.

jah wobble metal box rebuilt in dub vinyl

Quality, precision and performance are the factors that play a key role in the success of any enterprise. Om Shiv Industries offers all this and more, ever since its inception in the year 1984. We are an acclaimed manufacturer and supplier of Sheet Metal Components, Sheet Metal Cabinets, P.A. System Cabinets, Power Supply Cabinets, Heat Sinks, etc.Bonded-fin heat sinks generally offer moderate performance and come at a high cost. #3 – Skived Heat Sinks. Heat sinks produced through this method are normally made from copper. They are produced from a solid block of metal. These heat sinks offer high design flexibility and you can achieve high fin-density.Supplier and Manufacturer of Sheet Metal Components and Heat Sinks offered by Sidh Engineers, Ghaziabad, Uttar Pradesh, India. Sheet Metal Components & Heat Sink. We provided best quality Heat Sink and Sheet Metal Components which reflects high durability and export quality. They can be sued in various engineering and other allied industries.Be-Cu is Custom manufacturer of heat sink die castings.We have accomplished operators in the workshop to execute each operation in a correct way to ensure the products meet or exceed international standards and customer expectations. . we offering 5 and 3 axis,Laser Cutter,3D Printer,Sheet Metal Machine,Casting Machie,EDM,Injection Molding .

what is a heat sink computer

Buy 100mm x 200mm x 0.07mm Ultra-Thin Graphite Film, GTS Heat Sink Sheet, . The surface can be combined with other materials such as metal, plastic, and self-adhesive to meet more design functions and needs. 6. Widely used in smart electronic products. Typical applications include handheld mobile phones, notebook computers, video cameras . A bonded fin heat sink has a few advantages over other heat sink technologies. For one, the aspect ratio between the fin gap and fin height exceeds anything you can produce with extrusion. You can get a 60:1 ratio with a bonded fin assembly, where extrusions can only get up to a 20:1 ratio. Besides the aspect ratio, you have the sheer height .

types of heat sinks

Used cnc milling machines for sale in Wisconsin, USA. Bridgeport. Find used vertical milling machines and horizontal milling machines on Machinio.

sheet metal heat sink|active liquid heat sink