cnc gear parts processing factory google-site-verification=MiH5HyAKz6JC8rPogNmZOYiDDUtyzVqRRfVWzKLTzhM . Check out our v shaped table leg selection for the very best in unique or custom, .

0 · hobbing gear manufacturing

1 · gear machining process

2 · custom cnc machining

3 · cnc machining parts

Enter the expression you want to factor in the editor. The Factoring Calculator transforms complex expressions into a product of simpler factors. It can factor expressions with polynomials involving any number of vaiables as well as more complex functions.

We have our own factory that provides comprehensive precision metal and plastic parts processing services. All our parts and equipment are certified by ISO 9001:2015 and .

CreateProto pioneers CNC machining, rapid prototyping, revolutionizing industries .google-site-verification=MiH5HyAKz6JC8rPogNmZOYiDDUtyzVqRRfVWzKLTzhM .

Our advanced techniques, including custom 3D printing, sheet metal fabrication, .

Low-volume manufacturing and CNC machining offer a plethora of benefits, .With CreateProto, you can create functional end-use parts for industrial applications, .Validation of Feasibility: A Proof of Concept (POC) furnishes tangible proof that a .

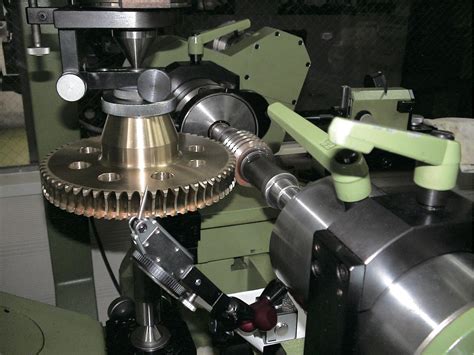

Our factory has several gear processing equipment and ancillary equipment such as gear hobbing machines, CNC gear shaping machines, CNC forming gear grinding machines, etc., specializing in the research and development, design, .As a professional CNC lathe processing factory, We provide customized CNC machining services and complete engineering solutions, not only based on customer drawings or requirements but also with professional engineering .InvoMilling™ is a process for machining external gears, splines and straight bevel gears that allows for in-house gear milling in standard machines. By changing the CNC program instead of changing the tool, one tool set can be used for many .

We are a manufacturer specializing in customized processing of parts in any field, with advanced equipment and technical personnel. Solve all the problems in the processing and customization fields for you! SHENZHEN PSSE METAL .Equipped with a professional factory, Wingfat Metal is one of the best manufacturers and suppliers of custom CNC lathe processing parts in China.We have our own factory that provides comprehensive precision metal and plastic parts processing services. All our parts and equipment are certified by ISO 9001:2015 and IATF16949. Whether it's injection molding, custom CNC milling, metal fabrication, or custom 3D printing, we ensure the development of your product design with the finest details.Our factory has several gear processing equipment and ancillary equipment such as gear hobbing machines, CNC gear shaping machines, CNC forming gear grinding machines, etc., specializing in the research and development, design, surveying and mapping, manufacturing, processing and sales of various specifications of gears and internal gear rings.

As a professional CNC lathe processing factory, We provide customized CNC machining services and complete engineering solutions, not only based on customer drawings or requirements but also with professional engineering advice and reverse engineering analysis.InvoMilling™ is a process for machining external gears, splines and straight bevel gears that allows for in-house gear milling in standard machines. By changing the CNC program instead of changing the tool, one tool set can be used for many gear profiles.

hobbing gear manufacturing

We are a manufacturer specializing in customized processing of parts in any field, with advanced equipment and technical personnel. Solve all the problems in the processing and customization fields for you! SHENZHEN PSSE METAL TECHNOLOGY CO., LTD. Hcompany is engaged in the machining industry for many years.Equipped with a professional factory, Wingfat Metal is one of the best manufacturers and suppliers of custom CNC lathe processing parts in China.This article will take you back to gear manufacturing, covering their common types and application, the processes that manufacture gear, and post-processing for gear manufacturing. Contents hide 1 Common Types of Mechanical Gears and Their ApplicationsIn this section, we lay the groundwork by explaining the fundamentals of gear manufacturing. From gear design principles to material selection, we explore how each decision impacts the final product. Designing gears requires a blend of precision and creativity.

24 x 24 16 gauge sheet metal

Specialize in CNC Milling, CNC Turning, 3D Printing, Urethane Casting, and Sheet Metal Fabrication Services. Gears have persisted for centuries, making them one of the oldest yet still pertinent mechanical elements today. CNC gears are important basic parts in industrial production. Their processing quality and processing capacity can reflect the industrial level at that time. The current development trend of gear processing is to realize the CNC and automation of gear processing, and the integration of processing and testing.

We have our own factory that provides comprehensive precision metal and plastic parts processing services. All our parts and equipment are certified by ISO 9001:2015 and IATF16949. Whether it's injection molding, custom CNC milling, metal fabrication, or custom 3D printing, we ensure the development of your product design with the finest details.

22g sheet metal

gear machining process

Our factory has several gear processing equipment and ancillary equipment such as gear hobbing machines, CNC gear shaping machines, CNC forming gear grinding machines, etc., specializing in the research and development, design, surveying and mapping, manufacturing, processing and sales of various specifications of gears and internal gear rings.As a professional CNC lathe processing factory, We provide customized CNC machining services and complete engineering solutions, not only based on customer drawings or requirements but also with professional engineering advice and reverse engineering analysis.InvoMilling™ is a process for machining external gears, splines and straight bevel gears that allows for in-house gear milling in standard machines. By changing the CNC program instead of changing the tool, one tool set can be used for many gear profiles.

We are a manufacturer specializing in customized processing of parts in any field, with advanced equipment and technical personnel. Solve all the problems in the processing and customization fields for you! SHENZHEN PSSE METAL TECHNOLOGY CO., LTD. Hcompany is engaged in the machining industry for many years.

Equipped with a professional factory, Wingfat Metal is one of the best manufacturers and suppliers of custom CNC lathe processing parts in China.This article will take you back to gear manufacturing, covering their common types and application, the processes that manufacture gear, and post-processing for gear manufacturing. Contents hide 1 Common Types of Mechanical Gears and Their ApplicationsIn this section, we lay the groundwork by explaining the fundamentals of gear manufacturing. From gear design principles to material selection, we explore how each decision impacts the final product. Designing gears requires a blend of precision and creativity.

Specialize in CNC Milling, CNC Turning, 3D Printing, Urethane Casting, and Sheet Metal Fabrication Services. Gears have persisted for centuries, making them one of the oldest yet still pertinent mechanical elements today.

custom cnc machining

Is It Okay To Cover a Utility Box? Before you hide a utility box with landscaping, check local regulations and ensure it’s safe. Some boxes, like gas, water, and cable, can be covered if they remain accessible for maintenance. However, electrical boxes usually need clearance and shouldn’t be obstructed.

cnc gear parts processing factory|hobbing gear manufacturing