making a cone out of sheet metal The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height . From corner braces to shelf brackets, the versatility of metal brackets makes them a must-have item in your toolkit. Explore our wide selection of metal brackets designed to meet your specific needs and help you complete your projects with confidence and precision.

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

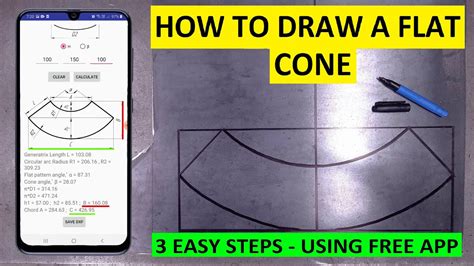

6 · cone sheet metal calculator

7 · cone layout formula

It's critical to match the metal roofing color to your house. You want the color to blend in with your neighborhood, environment, and property. It should complement all of the surrounding features. Your metal roof should blend in nicely with your stucco, siding, or brick and create a balanced look. Metal Roofing Colors And Styles

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone. Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .

Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago. .more. Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height .

Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size . How To Build A Steep Cone in Sheet Metal. Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted several.

Fabricating a cone with sheet metal requires precision and expertise from professional metal fabricators like the experienced team at Avon Lake Sheet Metal. By choosing the right material, accurately calculating the .

Step 1: Draw Elevation View & Plan View for Full Cone Shape. Step 2: Divide Top View Circle of Cone in equal no. of Parts. Step 3: Measure Slant Height of the Cone in elevation view. Step 4: Draw Development Circle with Radius as Slant . Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I'm here to alleviate your worries and provide you with the correct workflow. #MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late.

The workshop has this piece of machinery that rolls sheet metal to bend it to a curve, but as far as I can tell it will only produce a curve in one way. So a cone would be fine, but the parabolic shape requires curves in two directions and .

and cutout , to make perfect cones. that other cone program ain't it. W. winchman Stainless. Joined Jun 19, 2003 Location Thomasville, GA. Aug 28, 2005 #13 Marv, . The patern of the cones are a half circle cut out of a 13" wide strip of sheet metal. So the question is - is there a source of a simple machine that I have missed, or even . Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this blog post, the experts at Avon Lake Sheet Metal will guide you through the steps we take when fabricating a cone with sheet metal for . Next, use the tin snips to carefully cut out the circular shape. Make sure to follow your marked line precisely to ensure accuracy. Step 3: Forming the Cone Shape . Making a sheet metal cone may seem daunting at first, but with the right tools and step-by-step guidance, it becomes a straightforward process. By following this guide, you can . Make a straight line on the cone from the top to the bottom. Place the cone back onto the construction paper, with the line you drew facing up. Wrap the paper around the cone. With a pencil, make a line from the top of the cone to the bottom, on the construction paper where the paper overlaps the line on the cone.

Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I’m here to alleviate your worries and provide you with the correct workflow. I typically like to start my first sketch on the Top Plane. Using my sheet metal open sketch technique, we can draw an arc and its construction lines. With the radius (or diameter) dimension .

Layout a half profile of your cone as shown. transfer the NR radius to base line and drawl an arc or circle. CR will be your cut radius, you can then either step off the length needed (new radius X 3.1416) on the CR arc with a divider or figure the difference in circumference between the two radia CR - R = amount to cut that out of the circle pattern. I wanted to make a transition fitting for my dust collector, that would go from 10" diameter at the top to 4" diameter at the bottom - basically a big funnel to drop sawdust into a bucket. I remembered from pre-school that you can take a circle of paper, cut a wedge out of it, and it will make a cone. Cut the bottom off the cone, and there you go. I have done this, but you wont really like the answer. The way you do it is, you special order a 3000 series soft aluminum sheet. Then, using a shot filled leather bag and a rounded mallet, you rough shape it, then you smooth it out with an english wheel, then you repeat as needed to get the right shape.

There are many reasons that you might need to bend a cone from sheet metal. Metal cones are good for finishing chimneys, topping off certain types of outdoor fire and grill buildings and occasionally for decor purposes. . Cut this circle out with your sheet metal shears. Wear gloves for this, since the edges of the metal can be very sharp .

This Tutorial is about how to design a Cone of Sheet Metal in SOLIDWORKS. Lofted Bend and Flatten commands are used for this design. Flattened view shows ho.

What you are trying to do is literally mathematically impossible. A cone can be flattened. A parabolic contour cannot. What you will need to do if you’re adamant about making a parabola from sheet metal is accept some “faceting” of the shape and make an approximate parabola that’s actually a bunch of cones with changing angles. Learn how to convert a solid cone into sheet metal, and pattern a cut feature along a curve driven pattern at the flat pattern level.For more information abo.Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size .

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt.Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Industry, Process Equipment Manufacturing Industry, Pressure Vessel Manufacturing Industry, . I have been intrigued with this shortcut, which you may find of interest. Cones have several uses, such as sheet-metal chimney caps, but the layout of a cone is puzzling to some craftsmen. Here is a fast method that doesn’t require higher mathematics. The example shows how to lay out a cone 6 in. high with a 24-in. dia. base.

In this video I make a sheet-metal slip roll for shaping cones and cylinders. The tool I made is quite small, but yet very rigid due to the variable width de. Secure the cone along the seam. Gluing the cone will give the nicest finish, or a piece of tape or staples can be used. If taping the cone, place the tape on the inside and outside of the cone to keep the flaps down. A glue stick will work for this, but liquid glue will hold better. SolidWorks II Sheet Metal II Four Ways To Create Sheet Metal - ConeIn this video, I am going to explain Four difference ways to create Sheet Metal - Cone----.

truncated cone from flat sheet

Sheet metal chapter 17. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. All lines must radiate from a common _____ for radial line development to be used. Center. 1 / 22. . The stretch out arc is swung half the stretch out diameter when developing a cone pattern. False. Patterns for truncated right cones are developed using radial line .

Make sure to purchase a large enough roll of sheet metal to make the desired size. Be aware that the edge of the metal is razor sharp, so you may need to buy more than you need. To make the baffle more durable, you can cut the metal baffle to fit the trunk of the tree. A quick how-to showing my favorite way to make a cone from 3 measurements. All you need to know is the small diameter, the large diameter and the height. Che.The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . “You all helped us out greatly when no one else seemed they could. Everything worked out wonderfully!”

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Use a drill with a small metal drill bit to make the holes. Start with a few holes and gradually increase the number and size based on your preference. Remember to wear your protective gear throughout this step. Step 4: Form the Cone. Now, carefully shape the flat sheet metal into a cone by overlapping the edges and securing them together.

electrical box green

electrical box hatch fasteners

Claim: Five-pointed stars decorating the exteriors of houses mean the inhabitants are "swingers."

making a cone out of sheet metal|sheet metal cone formula