cnc machine code list List of G-codes commonly found on Fanuc and similarly designed . The most common types of electrical boxes include junction boxes, outlet boxes, switch boxes, and ceiling boxes. Junction boxes are used to connect wires and cables, while outlet boxes are used to house electrical outlets.

0 · list of all g codes

1 · g code table listing

2 · complete g code list

3 · cnc turning g codes list

4 · cnc milling g codes list

5 · cnc machine codes list pdf

6 · cnc machine code example

7 · cnc g code list download

Power poles are vertical structures that are used to support electrical power lines. They play a crucial role in the distribution of electricity from power plants to homes, businesses, and other facilities. Power poles are typically made of wood, steel, or concrete, depending on the specific requirements and environmental conditions.

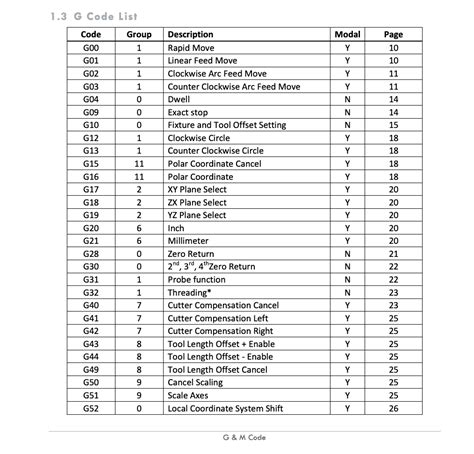

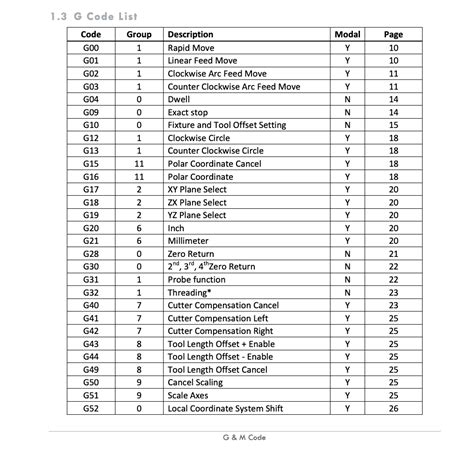

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.Check out our guide to every CNC code including multiple examples to help you .

CNC G-codes & M Codes for milling and turning with explanations, .

sheet metal union indianapolis

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections . List of G-codes commonly found on Fanuc and similarly designed .Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining .

G Codes are used to make CNC Machines programmable and give CNC machines the flexible to make almost any part. CNC machines use G and M codes for CNC programming. These codes tell the machines what EXACTLY .

list of all g codes

Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code.CNC (Computer Numerical Control) machines operate based on coded instructions that dictate their movements and operations. These instructions are written in G-code and M-code, which are essential for machining processes.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.

List of G-codes commonly found on Fanuc and similarly designed cnc controls.G code are also called preparatory codes (preparatory functions). To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential.

Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining centers. In a typical CNC program, G-codes and M-codes are used in combination. G Codes are used to make CNC Machines programmable and give CNC machines the flexible to make almost any part. CNC machines use G and M codes for CNC programming. These codes tell the machines what EXACTLY they should do, including: When to move ; Where to move ; How to move Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code.

CNC (Computer Numerical Control) machines operate based on coded instructions that dictate their movements and operations. These instructions are written in G-code and M-code, which are essential for machining processes. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

sheet metal union ottawa

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.List of G-codes commonly found on Fanuc and similarly designed cnc controls.G code are also called preparatory codes (preparatory functions). To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential.

Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining centers. In a typical CNC program, G-codes and M-codes are used in combination.

g code table listing

complete g code list

G Codes are used to make CNC Machines programmable and give CNC machines the flexible to make almost any part. CNC machines use G and M codes for CNC programming. These codes tell the machines what EXACTLY they should do, including: When to move ; Where to move ; How to move Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code.

sheet metal training

cnc turning g codes list

Factors to Consider When Selecting the Best Glue for Metal to Wood Bonding: Epoxy: Provides high bond strength and durability. Cyanoacrylate (super glue): Offers fast bonding but may not be as strong as epoxy. Polyurethane: Known .

cnc machine code list|g code table listing