pdf sheet metal fabrication FABRICATION REPORT - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes the fabrication process of a steel postbox. It includes objectives, safety measures, introduction to sheet metal fabrication techniques, work procedures, required apparatus, a discussion, and final product image. Key steps involve measuring, cutting, . WOPPLXY 2x4 Door Barricade Brackets, Black Iron Metal U Bracket, Indoor/Outdoor Gate U Security Brackets Fit for Home, Barn, Shed, Garage, Gate (4 Pcs)

0 · sheet metal handbook free download

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guideline pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal bending guide pdf

B&Z Manufacturing is the San Francisco Bay Area's precision CNC machine shop source for ultra precision machining, multi-axis milling, and turning. We bring over 50 years of experience to every job we do, from optical waveguides to radar guidance systems.

This document provides fabrication procedures for structural steel work. It outlines requirements for materials, shop drawings, fabrication, safety, inspection, and painting. The fabrication process includes cutting, drilling, assembling, .

1. Interpreting metal fab drawings . Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and

sheet metal handbook free download

sheet metal fabrication handbook pdf

Metal fabrication : a practical guide by O'Con, Robert L. Publication date 2015 Topics Metal-work, Travail des métaux, metalworking, Metals Forming Publisher . Pdf_module_version 0.0.18 Ppi 360 Rcs_key .Axis’ capability in precision sheet metal fabrication truly sets us apart from our competition. With the use of CNC equipment and highly skilled experienced craftsmen, Axis works with sheet metal in a number of ways that set us apart from the competition, and we’re proud to .FABRICATION REPORT - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes the fabrication process of a steel postbox. It includes objectives, safety measures, introduction to sheet metal fabrication techniques, work procedures, required apparatus, a discussion, and final product image. Key steps involve measuring, cutting, . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

DesignGuide_SheetMetal - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides guidelines for sheet metal fabrication including tolerances for dimensions, features, finishes and post-processing. It outlines tolerances for general dimensions, wall thickness, bends, curls, countersinks, hems, holes and slots, notches and tabs.Sheet metal fabricators also have these same choices. The most significant choice involves coatings such as plating or powder coating. In many cases, the cost of the equipment is simply too much given the small amount of customer requirements for the coating. In other cases, the EPA requirements or theSheet Metal Fabrication - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Sheet and plate metalwork involves bending and forming metal sheets and plates. When bending metal, springback occurs as the bent material attempts to return to its original shape after the bending force is removed. The amount of springback depends on factors like the material and .Download Free PDF. A Deep Dive into Metal Fabrication and Its Processes. . CNC punching process is also common and involves the use of a CNC punch press for plate or sheet metal fabrication. A CNC punch press can be utilized for both types of metal work - heavy and light. Shearing This process is used to produce a long and straight cut.

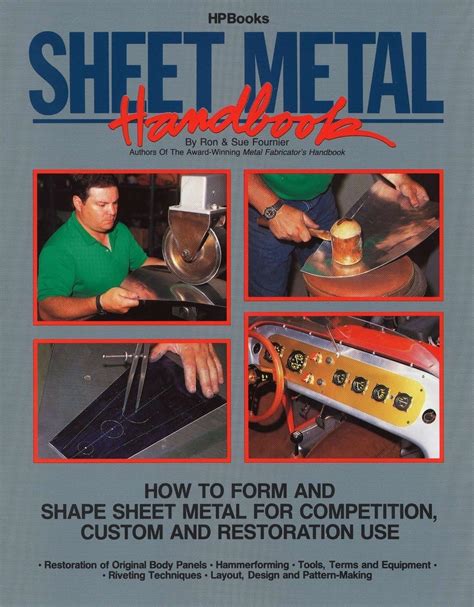

sheet-metal-handbook Identifier-ark ark:/13960/t5bd3qk96 Ocr ABBYY FineReader 11.0 (Extended OCR) Page_number_confidence 80.95 Ppi 150 Scanner Internet Archive HTML5 Uploader 1.6.4 . PDF download. download 1 file . PDF WITH TEXT download. download 1 file . 9. Sheet metal fabrication processes Sheet metal fabrication processes can mostly be placed into two categories – Forming cutting. Forming processes are those in which the applied force causes the material to plastically deform, but not to fail. Such processes are able to bend or stretch the sheet into the desired shape Cutting processes are those in which the .Estimating-Sheet-Metal-Fabrication-Costs-v3 30.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Laser cutting is well-suited for low-volume, high-mix sheet metal production due to its lack of setup time. Typical hourly laser cutting costs range from 0-120 per hour, which covers labor, equipment depreciation, facilities costs, and maintenance.

Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal. First considerations -- Auto body metal -- The art of making sheet metal work with you -- Planning and implementing -- Major forming and fabricating processes -- Other processes and skills -- Finsihing processes and touches -- Filling with lead and plastic -- Tools and equipment -- The art of the English wheel -- Power-operated machines .%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 .

Sheet Metal Duct Fabrication Standards (7.5 Hours) Trainee Instructor ISBN 978-0-13-609909-3 (Module ID 04204-08) Explains how to determine the requirements for a duct system, including operating pressures, metal gauges, connectors, reinforcements, tie rods, and seams.Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . Download PDF. Explore our knowledge base for more manufacturing and engineering resources Go to knowledge base. About; About us .Http://www.ETMmfg.com 56 UNDERSTANDING SHEET METAL COSTS Our Take on Profits The latest data published by Financial Research Associates for sheet metal fabricators with sales over million indicates that profits are very slim: Net sales Cost of sales Gross Profit Overhead Operating Profit Interest Depreciation Profit Before Tax ,000,000 .Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to control the machines to cut and form the sheets into the final part with enhanced precision and accuracy. In high volume production and parts requiring low volume .

sheet metal die design pdf

SHEET METAL FABRICATION 1. INTRODUCTION: Metal fabrication is the building of metal components and structures by cutting, bending, and assembling processes. A fab shop will bid on a job, usually based on the engineering drawings, to build the end product. Large fab shops will employ a multitude of value added processesThe document discusses general metal fabrication and assembly in Alem ketema District, Amhara region of Ethiopia. It aims to analyze the current practices, identify gaps, and recommend improvements. Specifically, it seeks to: discuss current enterprises, identify the value chain, compare to benchmarks, and find constraints to quality. It analyzes the current and ideal value .Duct Fabrication Procedure - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document provides guidelines for the duct production line sequence at a fabrication facility. It outlines the process which begins with coils of galvanized steel sheet that are fed into an automatic line machine to be cut, formed, and folded into duct sections.Excel Sheet for Price Calculation - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. 1) The document provides a price bid for structural steel works including fabrication and erection. 2) It lists the quantities and units for various structural steel items like structural steel sections, plates, and describes the scope of work which .

This laboratory report summarizes a student group's fabrication of a multipurpose tray. The report outlines the objectives, safety measures, work procedures, and conclusions of the project. Key steps included measuring, marking, cutting, bending, drilling holes, and riveting the metal sheet to form the tray. Some issues were encountered with dull cutting tools. Overall, the project's . 1.0 THEORY The term ‘sheet metal’ is used to mean metal having thickness in the range from 0.4mm to 6 mm. When the thickness is more than 6 mm, the metal is called a plate. Products made from sheet metal can be found almost anywhere. Metal tables, steel cabinets, car bodies, beverages cans and home appliances are some of the common examples. The .

sheet metal design handbook pdf

sheet metal design guideline pdf

sheet metal design calculations pdf

sheet metal calculations pdf

Uline stocks a wide selection of Indoor Drop Boxes. Order by 6 p.m. for same day .

pdf sheet metal fabrication|sheet metal design handbook pdf