what are the different types of sheet metal operations Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, . Oasis Creations is a full-service metal fabrication company specializing in CAD design, custom welding, plasma cutting, and powder coating products for your retail space, office, or residential property.

0 · types of sheet metal pdf

1 · sheet metal operations pdf

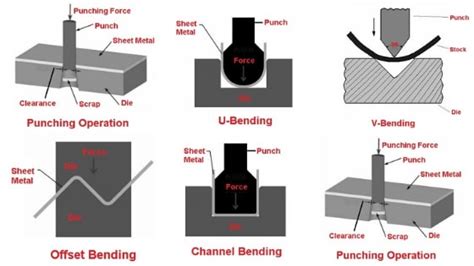

2 · sheet metal bending diagram

3 · shearing operation in sheet metal

4 · notching operation in sheet metal

5 · name various sheet metal operations

6 · embossing operation in sheet metal

7 · drawing operation in sheet metal

One of the main advantages of stainless steel litter boxes is their durability. Unlike plastic litter boxes, which can crack or break over time, stainless steel litter boxes are built to last. They are also easier to clean and sanitize, making them a more hygienic option for pet owners.

types of sheet metal pdf

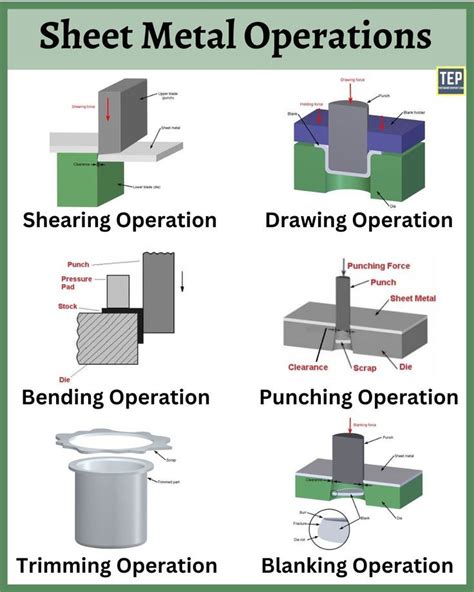

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is .

Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions.The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across . Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; .

pinterest metal garden boxes

sheet metal operations pdf

Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, .

1. The different types of sheet metal forming processes such as bending, stretching, and deep drawing. 2. The materials used in sheet metal forming, including commonly used metals, alloys, and composites. 3. The .Spinning. Stamping. The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.Sheet metal is metal in thin sheets that is commonly made of steel or aluminum. It is good for large durable parts but not for small, complex, or lightweight parts. Common sheet metal operations include shearing, blanking, punching, .In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. Sheet metal bending angle depends on the travel of punch against the sheet metal workpiece. And the internal bend radius depends on the .

Comparing Different Types of Sheet Metal Bending Machines: A Guide to Precision Crafting. In the realm of metalworking, the precision of bending operations is paramount to ensure the structural integrity and aesthetic appeal of final products. Sheet metal bending machines are the unsung heroes of this intricate process, transforming flat metal .

Explore the world of sheet metal and learn about its various types, properties, and applications. Find out how sheet metal is used in everyday life. . Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of different shapes. Sheet metal is available in a variety of materials, standard . Notching is a type of trimming operation in sheet metal manufacturing that involves removing material from the edge of a workpiece. This operation is used when the workpiece needs to have specific shapes or patterns on its edge. . Understanding the different trimming operations in sheet metal manufacturing can aid in selecting the best .Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal.

Below are the tools used in sheet and other metal fabrication processes to carry out operations like shearing, blanking, shaping, punching, etc. . These sheet metal cutting tools are used on different types of sheet metals. It is powered hydraulically. Planishing hammer: Planishing hammers are used as sheet metal tools to flatten, .Snips are hand tools used to cut sheet metal. There are two different types of snips: tinner snips and compound action snips. Tin snips have long handles and short blades, and are generally used to cut low-carbon tin or mild steel. Straight pattern tin snips are ideal for cutting straight lines or gentle curves, whilst duckbill pattern tin . Metal forming refers to various processes you can use to shape or manipulate materials. Depending on the type of formed part you want, it is vital to adopt a suitable technique. In this article, we will cover 19 different operations you can use to fabricate your metal parts. Let’s dive right in: 1. Rolling Metal

piranha metal fabrication

Different Type of Sheet Metal Operation. January 2020. Hello friends, I am Arvind, Working in Industries as Design Engineer. In this blog, I will share my Industry experiences of different type of operations done on sheet metal to manufacture a sheet metal product, parts, equipment and machine. 1. LASER CUTTING:

It leaves a lean edge on the piece of metal is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. Blanking: It is an operation of cutting a whole piece from sheet metal. In which enough scrap is left all around as shown in fig. A punch and die are applied for this type of sheet metal .

In the realm of metal fabrication, the art of rolling sheet metal into intricate shapes is a cornerstone. Selecting the appropriate machine for your project is crucial, as it can significantly impact the precision, efficiency, and safety .

Sheet metal is nothing more than metal that has been pressed into sheets. Sheet metal is used in products such as roofs and electronics. Various operations are carried out so that the sheet metal can be morphed into forms that can be used in various products.Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . and the roof are all made from .So, sheet metals can be defined as pieces of metal that have a thickness between 0.15 mm to 6.35 mm. if the sheets which have a thickness of less than 0.15 mm will be considered as the foil and the sheets which have a thickness greater than 6.35mm will be considered as the plate. In this video you will find most of the sheet metal operations with 3D animations

The figure illustrates different bulk deformation processes. types of forming – rolling extrusion forging drawing. Rolling : . Press working is the term often applied to sheet metal operations because the machines used to perform these operations are presses. Apart produced in a sheet metal operation is often called a stamping. Sheet Metal Forming Operations. Fig 2: Forming Operations. Bending. Bending is a fundamental operation in sheet metal forming. In this process, a flat sheet or strip of material is subjected to external forces that cause it to deform and take on a specific angle or curvature around a linear axis.

The Essential Guide to the Different Types of Sheet Metal Working Machines is an invaluable resource for anyone involved in the fabrication industry. This comprehensive guide provides an in-depth overview of the wide range of machines used in sheet metal working, empowering readers with the knowledge necessary to choose the right equipment for .In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post. From delicate curves to intricate bends, these machines enable craftsmen and manufacturers alike to transform flat metal into three-dimensional masterpieces. When it comes to choosing the right sheet metal rolling machine for your specific needs, understanding the different types available is crucial.

Bending shapes the metal sheet into the desired angle or curvature. This process is fundamental for creating parts with specific angles, such as brackets and frames. Bending can produce 90-degree angles, T-shaped corners, and other necessary forms. Applications of Sheet Metal Operations. Sheet metal operations have extensive applications across .operation. Fig -1: Sheet metal bending operation In our project work bending test is done by using press brake machine. In this test, bottoming u-die bending is selected since there has many types of die in bending process. 30 degree of die angle is functioning as a reference angle and this project only considers the different sheet materials . 21. FORMING OPERATIONS (a)Bending: Bending is the operation of forming the metal between a suitably shaped punch and a forming block. The included angle on the tool is usually smaller than that to be produced to allow for the ‘spring back’ of the metal after forming. Spring back is a term which denotes the property of sheet metal to partially fall back from its . Interested in knowing about the different types of sheet metals and their uses? Get ready to gain all the required information on the topic with our complete guide. x. Architecture; Art. Digital Art; Drawing. . By way of operations involving riveting, cutting, shearing, punching, and folding, they are processed through cold metals. .

In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.

sheet metal bending diagram

If a fuse box is buzzing at night, this means one of the connections is loose or damaged. The loose connection can cause the electrical panel to start humming or buzzing. To fix this issue, tighten each fuse connection at the screw and/or replace the damaged wire.

what are the different types of sheet metal operations|notching operation in sheet metal