how to strengthen sheet metal Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for stiffening panels or adding decorative elements to automotive parts. Buyers Products 1702510 Black Steel Truck Tool Box With Aluminum Diamond Tread Door, 18 x 18 x 48 Inch, Made In The USA, Truck Box for Organization & Storage, Job Tool Chest, Contractor Toolbox

0 · stiffening ribs in sheet metal

1 · shrinking and stretching sheet metal

2 · sheet metal strengthening ribs

3 · sheet metal stiffening techniques

4 · how to stiffen sheet metal

5 · how to flatten steel sheet

6 · how strong is sheet metal

7 · flaring operation in sheet metal

These 3 axis Rotary draw CNC tube benders are designed to take the .

Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for stiffening panels or adding decorative elements to automotive parts.3.99

Consider material and finishing options along with design elements like bends, reliefs, holes, and slots when developing sheet metal components. For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under .

Sheet metal is strong, durable, moldable, lightweight and cost-effective. For example, with sheet metal you can create lightweight yet structurally rigid parts, unlike bulky casting or machined parts.

"Strengthen" is not actually the correct term, stiffen is, although most car shows use them interchangeably. Thin material stock like sheet metal is really only stiff in one direction, that is it resists deformation in the direction with most material.To meet unique sheet metal design challenges like manufac-turability, Solid Edge streamli-nes the entire sheet metal product development process, from CAD design through flat pattern and drawing development. Unlike general-purpose CAD tools, Solid Edge includes sheet metal-specific features like emboss, dimple, drawn cutout, In this video JD goes over exactly how to use the bead roller stretching dies. Motorized Bead Roller Dies: https://www.eastwood.com/eastwood-motorized-bead-r. For more sheet metal strengthening tips and tricks, visit the Eastwood Garage and How-To Center or call our tech experts at 1-800-343-9353. Eastwood also has a growing network of brick-and-mortar stores where you can speak to a real person and check out many of the tools we mentioned in this guide. We’ve been helping DIY auto body workers Do .

Hardening steel at home can be a rewarding skill, whether you're tackling a big project or simply want to strengthen your tools. It might seem intimidating if you're new to working with metal, but with a little knowledge and some basic tools, you can achieve great results without advanced equipment or years of experience.

metal wood bracket

stiffening ribs in sheet metal

After a piece of tempered sheet metal or aluminum is worked with a hammer for a while, it begins to get hard and brittle, so you may need to temper it again to be able to keep working it without cracking or splitting it. . That covers the basics of metal strengthening techniques and how those techniques influence a metal's microstructure . As such, excessive bends may cause the sheet metal to crack instead of strengthening it. There are several ways of bending sheet metal. The simplest involves clamping the stainless steel metal on a table and using your weight to bend it over. Alternatively, you can use a body hammer and the edge of a dolly to fold the metal to create a firmer bend.

Flanges make the process of creation of a sheet metal part quick and convenient. In the course of conceptualizing a flange, the following should always be taken into consideration – Flange width must never be less than four times the thickness of the sheet metal. On failing to do so, the tool of choice will leave a mark on the sheet metal . In sheet metal forming, the embossing technique can be used to strengthen sheet metal materials and to improve their properties. Increase in strength is achieved by strain hardening and residual . When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. . The primary reason for taking production time to stiffen and strengthen duct is compliance. SMACNA sheet metal standards deem that ductwork of various gauges should be put through a stiffening process .

Help strengthen sheet metal part I have this sheet metal part (1.2mm ss304) that is cracking due to fatigue at the joint shown in pic. Is there any way I can strengthen this area and keep the flanges where they are?

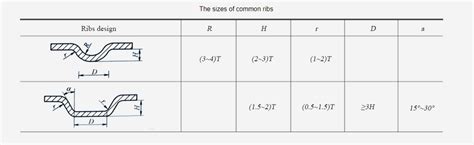

Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Beaded Emboss Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add strengthening .add big crossbraces, like that red one shown. the longer the cross brace, the stiffer it will make the structure. Steel angle iron will be fine. If the sheet metal is very thin, you might have to strengthen the sheet metal with a square patch where the angle iron attachesAt present, there are two mainstream methods to strengthen aluminum sheet metal in aluminum industry: it is strengthening in product process and solid-solution to strengthen the aluminum sheet metal. 1. Strengthening in Aluminum Sheet Metal Processing Strengthening in product process is also called the cold hardening, it is means aluminum sheet .

However, because the sheet metal parts are relatively thin, there are often challenges related to rigidity and strength under certain conditions. This article will introduce the 4 main design tips to enhance the strength (rigidity) of sheet . In addition to strengthening sheet metal panel, this method helps in enhancing the finish of the panel edges. Bead Roller - Use a bead roller to create various bead profiles and designs, which contribute in boosting the panel’s structural integrity. The tool is supplied with several dies with which you can create desired beads and steps.

Sheet Metal strengthening rib across a bend - SW 2020 Student version . Hello, Trying to learn SW and using a Student version. . The only exception is the feature called "Sheet Metal Gusset" but I doubt that is what you're looking for .

Choosing the right hardware and designing sheet metal to fit it is one of the most critical aspects of sheet metal manufacturing.Designing parts correctly for hardware can be difficult – countersinking material for flush rivets, picking the right depth of threading, ensuring the part is actually thick enough to accommodate screws. Solidworks Sheet Metal Gusset How to add strength to sheet metal bendsGussets in Solidworks Sheet MetalIn This Solidworks Sheet metal Tutorial, we are going .

shrinking and stretching sheet metal

Adding a front flange leg to adjust the lower mounting pad will bridge the sides of the bracket and help strengthen the part. (first view) Figure 4. Adding a front flange leg to adjust the lower mounting pad will bridge the sides of the bracket and help strengthen the part. . the manufacture of angle brackets in sheet metal is limited to the . Another way to strengthen sheet metal is through the use of rivets. Riveting can also be replaced by brazing. A MAPP gas torch and brass brazing rods are used to heat the joint. The brass is drawn into the joint by capillary action. In addition, hemmed seams can be used to join two edges. Another option for connecting two edges is a grooved seam.There are several things you can do to strengthen your metal shed: 1. Securely anchor the shed to the ground. You can do this by using concrete or metal anchors, making sure you securely attach them to the frame of the shed. 2. Add diagonal bracing across the wall frames. This will provide extra support and can reduce wear and tear.

This phenomenon of metal strengthening through the formation of a solid solution by dissolving a specific solute element is known as solid solution strengthening. When the . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. . SOLIDWORKS Sheet Metal Tutorial (Full Course 2hr:05min) playListhttps://www.youtube.com/playlist?list=PLx-VY2mDlK2H6eywmlpdQf2-Xpm_NqQxQvideo-tutorials.net Check Out Our FREE GUIDE: *25 Must-Have Carpentry Tools.Under Each!*https://www.thehonestcarpenter.com/AFFILIATE TOOL/MATERIAL LINKS:National Hardware . Hoping I can get some advice here: I'd like to learn a technique that would allow me to form strengthening ribs in sheet steel. Ultimately the sheet would be made into repair sections for my Land Rover footwells (actually both my Land Rovers need doing). . (correct terminology?) and just gently tapping the sheet metal into the shape with a .

Stretching is the process of extending the metal sheet in a certain direction. This process strengthens the sheet metal by orienting the metal’s grain in a certain direction. It also adds an aesthetic aspect to your sheet metal design. Stretching can be easily achieved by adding embosses, such as a formed punch or beaded emboss.

metal wedding cake boxes

Tri-Tec Industries | Precision CNC Machine Shop is located in Charlotte, North Carolina, and was founded in 1997. At this location, Tri-Tec Industries | Precision CNC Machine Shop employs approximately 12 people. This business is working in the following industry: Car repair.

how to strengthen sheet metal|sheet metal strengthening ribs